RFID Laundry Tracking & Linen Management System

Subtitle: Automating Linen Inventory, Washing Cycles, and Distribution with RFID Technology

Hotels, hospitals, industrial laundries, and uniform rental companies manage millions of pieces of textiles daily—bedsheets, towels, gowns, uniforms, tablecloths, and more. Traditional barcode systems or manual counting are labor-intensive, error-prone, and provide no real-time visibility. As a result, organizations struggle with:

Lost or stolen linens

Excessive replacement costs

Inaccurate inventory data

Delays in delivery cycles

Difficulty enforcing hygiene and compliance regulations

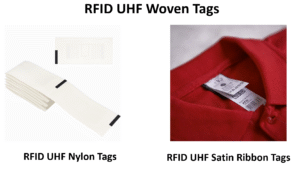

RFID technology provides a game-changing solution. By embedding washable RFID tags inside each textile, linens can be automatically identified, tracked, and managed throughout their entire lifecycle—from issuance, washing, sterilization, distribution, to disposal.

Our RFID Laundry Tracking & Linen Management System integrates RFID linen tags, tunnel/antenna readers, handheld readers, and cloud-based management software. It provides real-time visibility, accurate inventory counts, automated laundry operations, and significant cost savings.

Key benefits include:

24/7 linen visibility

Loss prevention & accountability

Automated inventory at hospitals, hotels, laundries

Extended linen lifespan through usage cycle monitoring

Compliance with health & hygiene regulations

This solution empowers hotels to enhance guest satisfaction, hospitals to ensure patient safety, and laundries to maximize operational efficiency.

Why Choose RFID Laundry Tracking

Accuracy & Automation

Count hundreds of items in seconds with RFID tunnels and readers.

No need for line-of-sight scanning, unlike barcodes.

Operational Efficiency

Reduce manual counting staff by up to 70%.

Automate check-in/check-out at laundry facilities.

Loss Prevention & Accountability

Each textile has a unique ID linked to its history.

Track when and where linens disappear (e.g., theft from hotels).

Lifecycle & Hygiene Monitoring

Record how many times an item has been washed.

Retire items automatically after exceeding washing limits.

Cost Savings

Reduce replacement costs by 20–30%.

Optimize stock levels to prevent over-ordering.

Scalability & Integration

- Works for small hospitals to multi-site hotel chains.

- Integrates with PMS, ERP, hospital information systems.

Application Scenarios

RFID Solution Hotels & Resorts

Hotels and resorts typically manage tens of thousands of pieces of linens daily, including bed sheets, pillow covers, towels, bathrobes, spa garments, and banquet textiles. Traditional methods like manual counting or barcode systems often lead to inventory mismatches, theft, and excessive replacement costs.

Challenges Faced by Hotels:

Frequent loss of linens due to theft or mishandling.

Inability to track linen usage per room or guest.

High operational costs from inaccurate inventory.

Slow housekeeping turnaround, affecting guest satisfaction.

How RFID Helps:

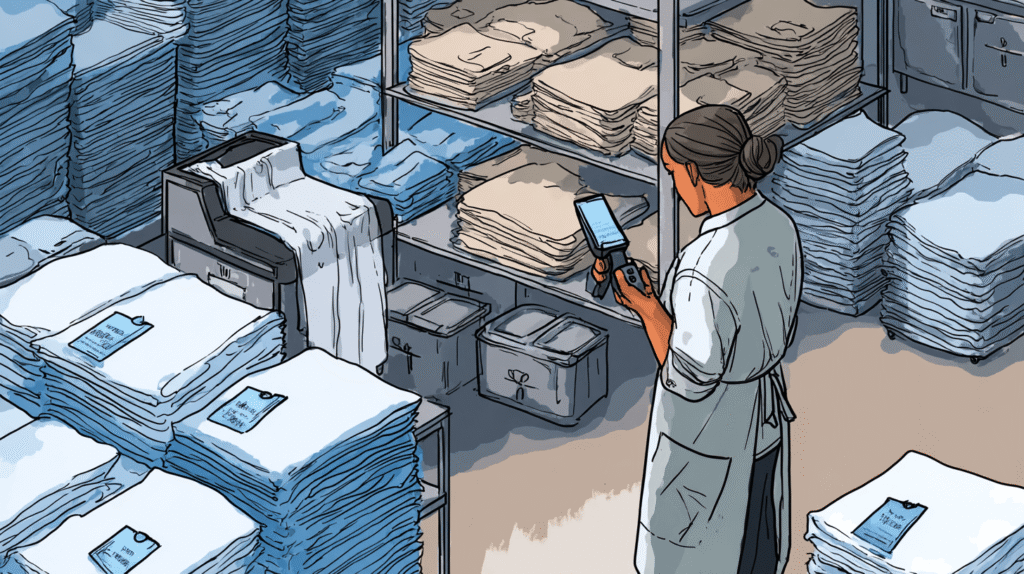

Real-time Visibility: Each linen item is fitted with a washable RFID tag. When housekeepers collect used linens, handheld RFID readers instantly count them.

Automated Inventory: Carts equipped with RFID readers can automatically record linens leaving or returning to laundry.

Loss Prevention: RFID exit gates at hotel service areas detect unauthorized linen removal, reducing theft.

Usage Optimization: Linen lifecycle data (e.g., number of washes) helps housekeeping teams retire worn-out items at the right time.

Guest Experience: Faster room readiness, ensuring fresh and hygienic linens are always available.

Use Case Example:

A luxury resort with 1,000 rooms embeds RFID tags in all linens. As housekeepers collect laundry, items are automatically scanned at the chute. Linen counts update in real-time on the PMS dashboard, ensuring managers know stock levels per floor. If a towel is taken outside the property, RFID gates alert security staff.

RFID Solution Hospitals & Healthcare

Hospitals and clinics manage critical medical textiles, including bed linens, surgical gowns, drapes, and uniforms. Unlike hotels, hospitals face strict hygiene regulations, where any tracking failure can risk infection control.

Challenges Faced by Hospitals:

Loss of surgical gowns or sterile drapes during laundry cycles.

Cross-contamination due to improper sterilization tracking.

Shortages of gowns or uniforms, delaying procedures.

Difficulty maintaining compliance with health authorities.

How RFID Helps:

Sterilization Compliance: RFID logs each washing and sterilization cycle, ensuring items meet hygiene standards.

Automated Sorting: RFID tunnel readers instantly sort linens for different departments (ER, ICU, OR).

Traceability: Patient-related linens (e.g., ICU bedding) can be tracked to ensure proper cleaning.

Stock Monitoring: Real-time dashboards show linen availability in wards, reducing shortages.

Regulatory Reports: Hospitals can generate audit reports automatically for inspections.

Use Case Example:

A hospital with 2,000 beds uses RFID to track every bed sheet and surgical gown. When gowns are sent to the laundry, tunnel readers record sterilization status. If a gown exceeds its wash cycle limit (e.g., 100 washes), the system automatically marks it for disposal, ensuring compliance and patient safety.

RFID Solution Industrial Laundries & Uniform Rental Services

Industrial laundries handle massive volumes of linens and uniforms for hotels, hospitals, factories, and catering companies. Manual methods often result in sorting errors, customer complaints, and billing disputes.

Challenges Faced by Industrial Laundries:

Sorting items for multiple clients is time-consuming and error-prone.

Difficulties in ensuring fair billing (per piece vs. weight).

Customer dissatisfaction due to misplaced or damaged items.

Lack of transparency in usage and cycle counts.

How RFID Helps:

Automated Sorting: Conveyor belts equipped with RFID tunnel readers automatically sort items per customer.

Accurate Billing: RFID counts every piece, allowing laundries to bill customers fairly and transparently.

Customer Transparency: Clients can log in to portals to view reports of how many items were washed, delivered, and retired.

Cycle Tracking: RFID monitors how many times uniforms have been washed, ensuring replacement at the right time.

Operational Efficiency: Laundries can reduce staff workload while increasing throughput.

Use Case Example:

An industrial laundry serving 20 hotels installs RFID tunnel readers on sorting belts. Each customer’s items are automatically sorted and counted. The system generates invoices based on RFID data, eliminating billing disputes and improving customer trust.

RFID Solution Restaurants & Catering Service

Restaurants, hotels with F&B operations, and catering businesses rely on thousands of textiles such as tablecloths, napkins, chef uniforms, and staff aprons. Manual management often leads to loss, misplacement, or hygiene issues.

Challenges Faced by Restaurants:

High turnover of napkins and tablecloths.

Missing chef uniforms or improper cleaning.

Difficulty maintaining consistent hygiene in catering services.

How RFID Helps:

Table Linen Management: RFID tags in napkins and tablecloths allow quick counting after events.

Uniform Hygiene: Chef jackets and aprons are tracked to ensure regular washing cycles.

Event Catering: RFID enables catering companies to track linen distribution across multiple event sites.

Reduced Losses: RFID detects missing or misplaced items in real time.

Use Case Example:

A catering service handling 50 events per week tags all napkins and uniforms with RFID. After each event, RFID handheld readers instantly count returns, reducing losses by 30%. Managers monitor item circulation through a centralized software platform.

How It Works: Deployment Process

Step 1: Tagging & Registration

Embed RFID tags inside each textile. Register each item with a unique ID.

Step 2: Laundry Check-In

As items enter the laundry, they pass through RFID tunnel readers for automated check-in.

Step 3: Washing & Sterilization

The system logs the washing cycle, sterilization status, and updates the item’s history.

Step 4: Sorting & Distribution

Clean items pass through readers and are sorted by customer, ward, or department.

Step 5: Delivery & Usage

Items are issued via RFID cabinets or handheld scans, ensuring accountability.

Step 6: Retirement

Once items exceed defined wash cycles, the system automatically flags them for replacement.

Specifications

| Specifications | RFID Linen Tag | Tunnel/Fixed Reader | Software Platform |

|---|---|---|---|

| Frequency | UHF 860–960 MHz | UHF 860–960 MHz | Cloud + API integration |

| Durability | 200+ wash cycles, heat & chemical resistant | IP65–IP67, industrial grade | Web + Mobile app |

| Read Range | Up to 3 m (handheld) | Hundreds of items simultaneously | Real-time dashboards |

| Compliance | RoHS, OEKO-TEX | CE, FCC | GDPR, ISO27001 |

FAQ

Q1: Are RFID linen tags washable?

Q2: How are tags attached to linens?

Q3: Does RFID interfere with washing or sterilization machines?

Q4: Can RFID track individual items, not just batches?

Q5: What’s the ROI?

Recommended Products

Anti-counterfeiting Tamper-proof Disposable NFC RFID Labels – Fragile Breakable Smart Label for Wine Bottles, Liquor Packaging, Cosmetics & Brand Protection

ISO 18000-6C UHF RFID Inlay – 860–960MHz Writable Passive RFID Label & Tag Sticker

Factory Customized UHF RFID Inlay Sheet – Long Range Passive Prelaminated RFID Label Sticker with UHF Chip

Get A Quote

Contact us to discuss your livestock or pet tracking needs. Our experts will recommend the right tags, readers, and software for your specific project.