RFID Factory Production & Automation Management Solution

Subtitle: Transforming Smart Factories with RFID: Real-Time Production Visibility, Automated Workflows, and Full Traceability

Introduction

Factories and production facilities are the foundation of global manufacturing. From automotive assembly lines and electronics plants to consumer goods and pharmaceuticals, industrial operations depend on precise production scheduling, material traceability, equipment efficiency, and real-time visibility.

Traditional factory management systems, often dependent on barcodes, paper logs, or manual processes, cannot keep pace with today’s challenges:

Complex supply chains demand real-time material tracking.

Lean manufacturing requires accurate just-in-time (JIT) workflows.

Industry 4.0 integrates machines, sensors, and data into smart factories.

Regulatory compliance requires full traceability of components.

These challenges create bottlenecks, inefficiencies, and risks in production output and quality control.

RFID Factory Production & Automation Management provides a breakthrough solution by enabling factories to automatically capture and process data at every step of production — from raw materials entering the factory to finished goods leaving the assembly line.

By tagging materials, components, work-in-progress (WIP), and finished products with RFID, factories achieve real-time visibility, improved automation, and higher production efficiency, enabling truly connected and intelligent operations.

Why Choose RFID in Factory & Automation

Real-Time Material Tracking – Monitor raw materials, parts, and WIP across the factory floor.

Improved Productivity – Automate manual scanning and reduce production delays.

Error Reduction – Prevent mix-ups, assembly mistakes, and mislabeling.

Enhanced Traceability – Track every component for compliance and quality assurance.

Machine Integration – RFID readers embedded in machines enable automatic process validation.

Predictive Maintenance – RFID + sensors track machine parts and trigger maintenance alerts.

Labor Efficiency – Free workers from manual record-keeping.

Data Analytics – Generate insights into line performance, downtime, and bottlenecks.

Application Scenarios

Raw Material & Component Traceability

Challenges:

Factories often lose visibility of materials once they enter the warehouse or shop floor. Manual handling leads to misplaced inventory, delays, and incorrect assembly.

RFID Solution:

RFID tags applied to raw materials and parts at supplier or receiving dock.

RFID portals at warehouse and factory entry points automatically log arrivals.

Materials are tracked as they move to production lines.

WMS and MES (Manufacturing Execution System) updated in real time.

Benefits:

Accurate material flow for just-in-time manufacturing.

Eliminates shortages and overstocking.

Reduces production stoppages due to missing components.

Work-in-Progress (WIP) Tracking

Challenges:

WIP items often get stuck in queues or misplaced between stations. Barcode-based systems require manual scans, slowing production and reducing visibility.

RFID Solution:

RFID tags on pallets, trays, or carriers.

Readers at each production station automatically record WIP movement.

MES updates progress and timestamps in real time.

Alerts triggered if WIP lingers too long at a stage.

Benefits:

End-to-end WIP visibility across the shop floor.

Balanced workloads and faster bottleneck identification.

Improved line efficiency and on-time delivery.

Tooling, Machine & Asset Management

Challenges:

Factories rely on specialized tools and machines. Misplaced tools, uncalibrated instruments, and unmonitored machine usage create safety and compliance risks.

RFID Solution:

RFID tags embedded on tools and machine components.

Smart cabinets log check-in/check-out of tools automatically.

Sensors + RFID track machine operating hours and usage cycles.

Maintenance schedules triggered by usage data.

Benefits:

Ensures availability of calibrated and safe tools.

Prevents downtime due to missing or broken equipment.

Supports predictive maintenance strategies.

Finished Goods & Quality Control

Challenges:

Incorrect labeling or incomplete QA checks cause defective products to reach customers, creating recalls, penalties, and brand damage.

RFID Solution:

Finished products tagged at final assembly.

RFID readers verify product completeness and QA test status.

Only approved goods pass RFID-controlled gates for outbound shipping.

Tags store batch data for future recalls.

Benefits:

Ensures 100% quality compliance.

Reduces costly recalls.

Improves customer trust with product traceability.

How It Works: Deployment Process

Inbound Materials – RFID tags applied to raw materials. Dock readers verify deliveries.

Storage & Allocation – Tagged materials tracked into warehouse storage and assigned to production.

WIP Tracking – RFID logs movement of semi-finished goods through production stages.

Tool & Equipment Monitoring – Smart cabinets and sensors track tool use and machine parts.

Quality Control – Finished goods verified and approved via RFID gates.

Outbound Shipping – Goods logged and dispatched with automated RFID portals.

Analytics & Reporting – Data feeds into ERP/MES for insights and optimization.

RFID Components for Factory Solutions

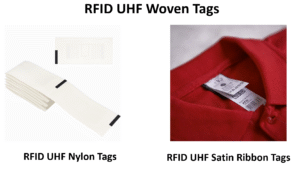

Tags

Heat-resistant tags for high-temperature processes.

Metal-mount tags for industrial tools and machines.

UHF passive tags for pallets and parts.

Active RFID + sensor tags for real-time machine monitoring.

Readers

Fixed readers on production lines.

Handheld readers for audits and inspections.

Embedded machine readers for automation.

RFID portals at factory entrances/exits.

Software

RFID middleware connecting devices with MES/ERP.

Dashboards for real-time production data.

Integration with Industry 4.0 IoT platforms.

Specifications

| Component | Specification |

|---|---|

| Frequency | HF 13.56 MHz, UHF 860–960 MHz |

| Read Range | 1–15m depending on environment |

| Tag Durability | High temp up to 200°C, IP67 industrial grade |

| Standards | ISO 18000-6C, EPC Gen2 |

| Integration | ERP, MES, IoT, Industry 4.0 platforms |

| Security | Encrypted tag data, role-based access control |

FAQ

Q1: Can RFID tags survive harsh industrial environments?

Q2: Does RFID integrate with MES and ERP?

Q3: What is the read accuracy in factories with metal interference?

Q4: Can RFID track both WIP and finished goods?

Recommended Products

RFID UHF Carrier Tag – Unlimited Read & Write Fujitsu ISO15693 Industrial RFID Tag for Small Pallets, Logistics & Smart Manufacturing

Industry 4.0 RFID Tag – High-Frequency 30mm Industrial Code Carrier for Automation, Smart Factory, and Manufacturing Execution Systems (MES)

Factory Customized UHF RFID Inlay Sheet – Long Range Passive Prelaminated RFID Label Sticker with UHF Chip

Factory Wholesale 125kHz Contactless Access Control PVC Smart Card – TK4100 RFID Proximity Blank Card for ID Badges, Hotels & Membership

Get A Quote

Boost productivity and traceability in your factory with RFID — request a customized solution and quote today.