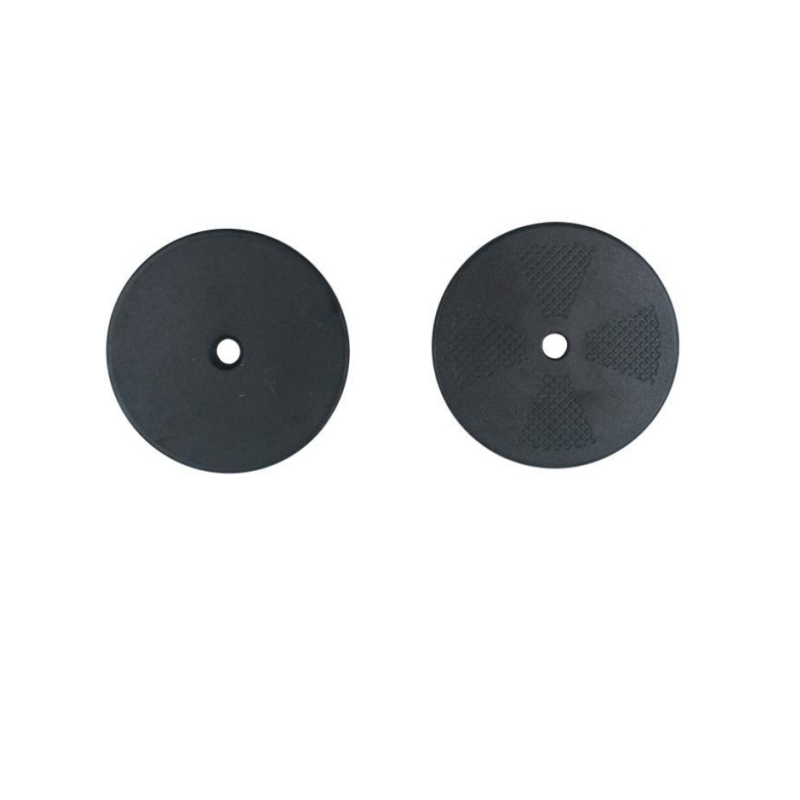

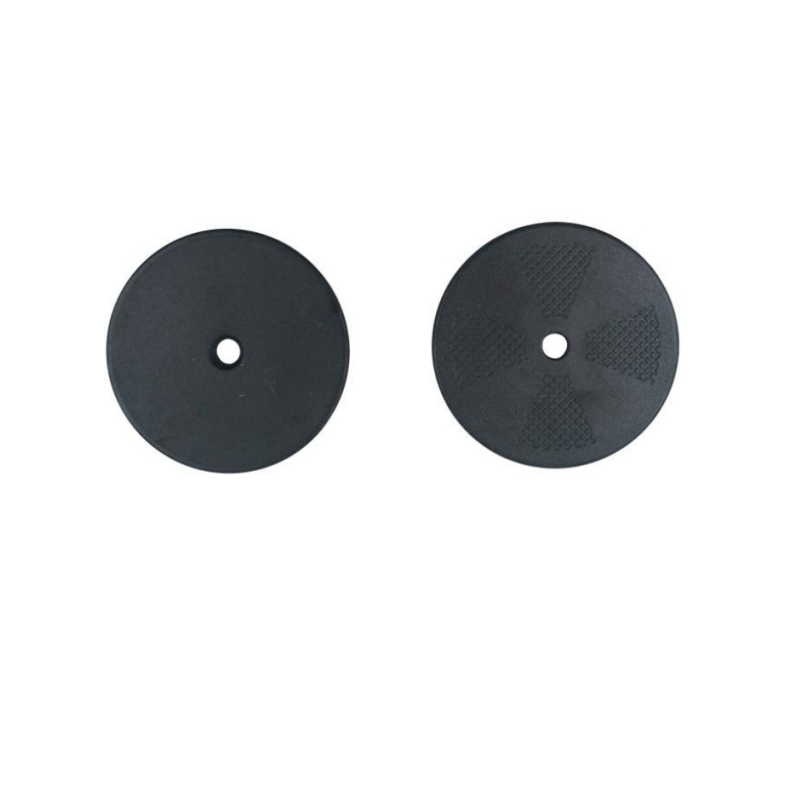

Industrial Carrier UHF RFID Tag – High-Temperature Resistant, Waterproof PPS Encapsulated RFID Landmark Tag for Manufacturing, Logistics & Asset Tracking

Product Overview

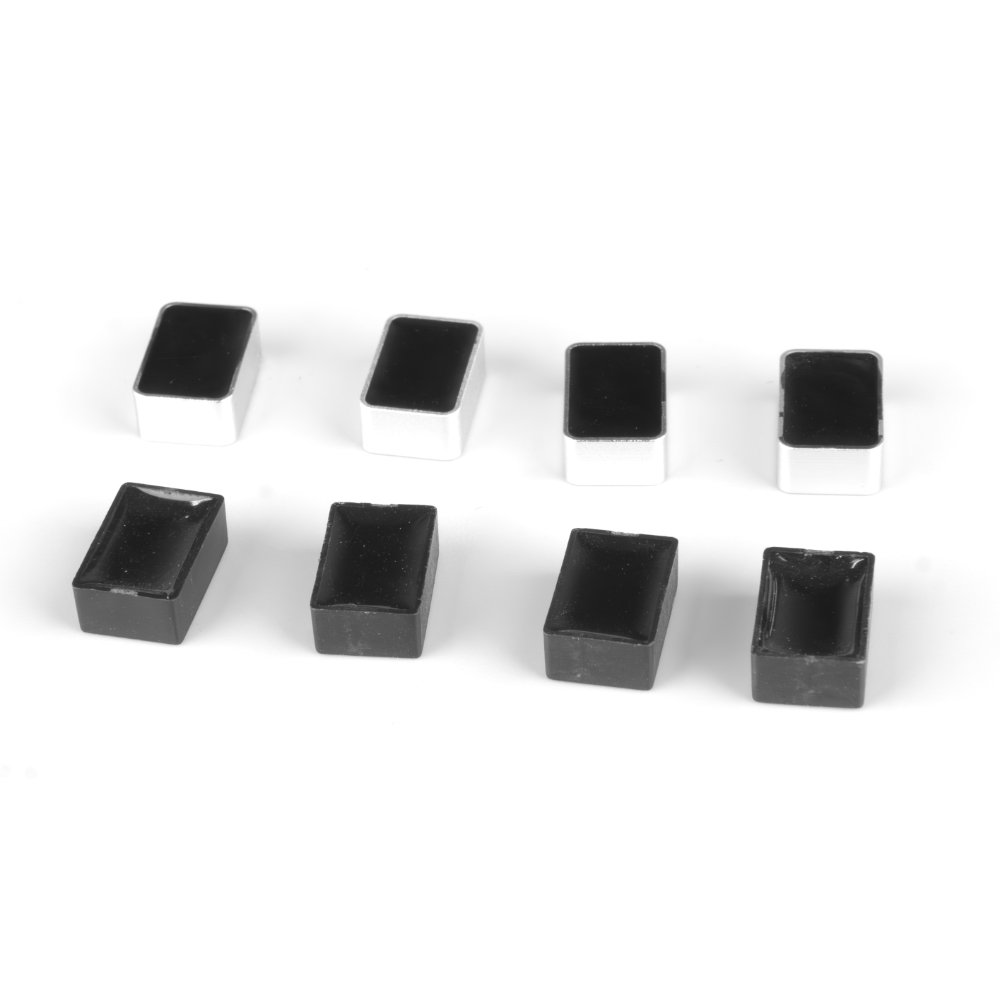

The Industrial Carrier UHF RFID Tag is engineered for harsh industrial environments, where traditional RFID tags fail due to extreme temperatures, exposure to chemicals, water, and mechanical stress. Built with high-performance PPS (Polyphenylene Sulfide) housing and advanced UHF chip technology, these tags ensure reliable identification, tracking, and asset management in demanding conditions.

Operating under the ISO18000-6C / EPC Gen2 protocol, the tags provide long read ranges of up to 10 meters, fast data encoding, and superior anti-collision performance. Their robust waterproof and heat-resistant design makes them suitable for automotive assembly lines, warehouse logistics, chemical plants, and outdoor infrastructure projects.

Unlike standard RFID labels, industrial carrier tags are reusable, designed for long life cycles, and can withstand continuous washing, sterilization, and chemical exposure, ensuring lower total cost of ownership (TCO).

Key Features

-

High-Temperature Resistance – Stable operation up to 200°C (short exposure).

-

Durable PPS Encapsulation – Resistant to chemicals, oils, water, and corrosion.

-

UHF Long-Range Communication – Up to 10 meters read distance with EPC Gen2 protocol.

-

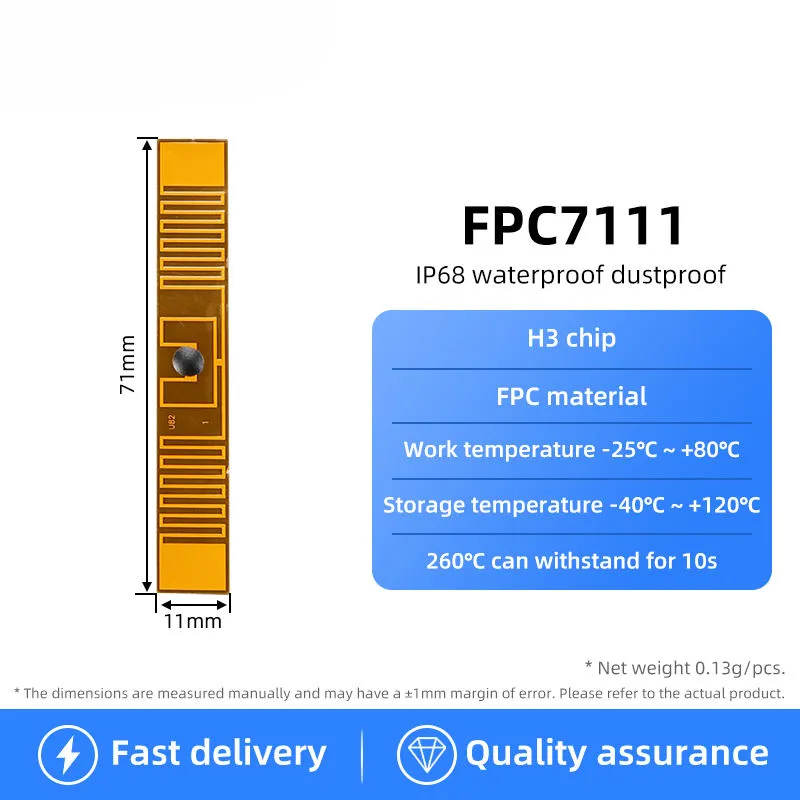

Waterproof & Dustproof – IP68 rating ensures reliability in outdoor and industrial environments.

-

Strong Mechanical Strength – Shock-proof and resistant to physical impacts.

-

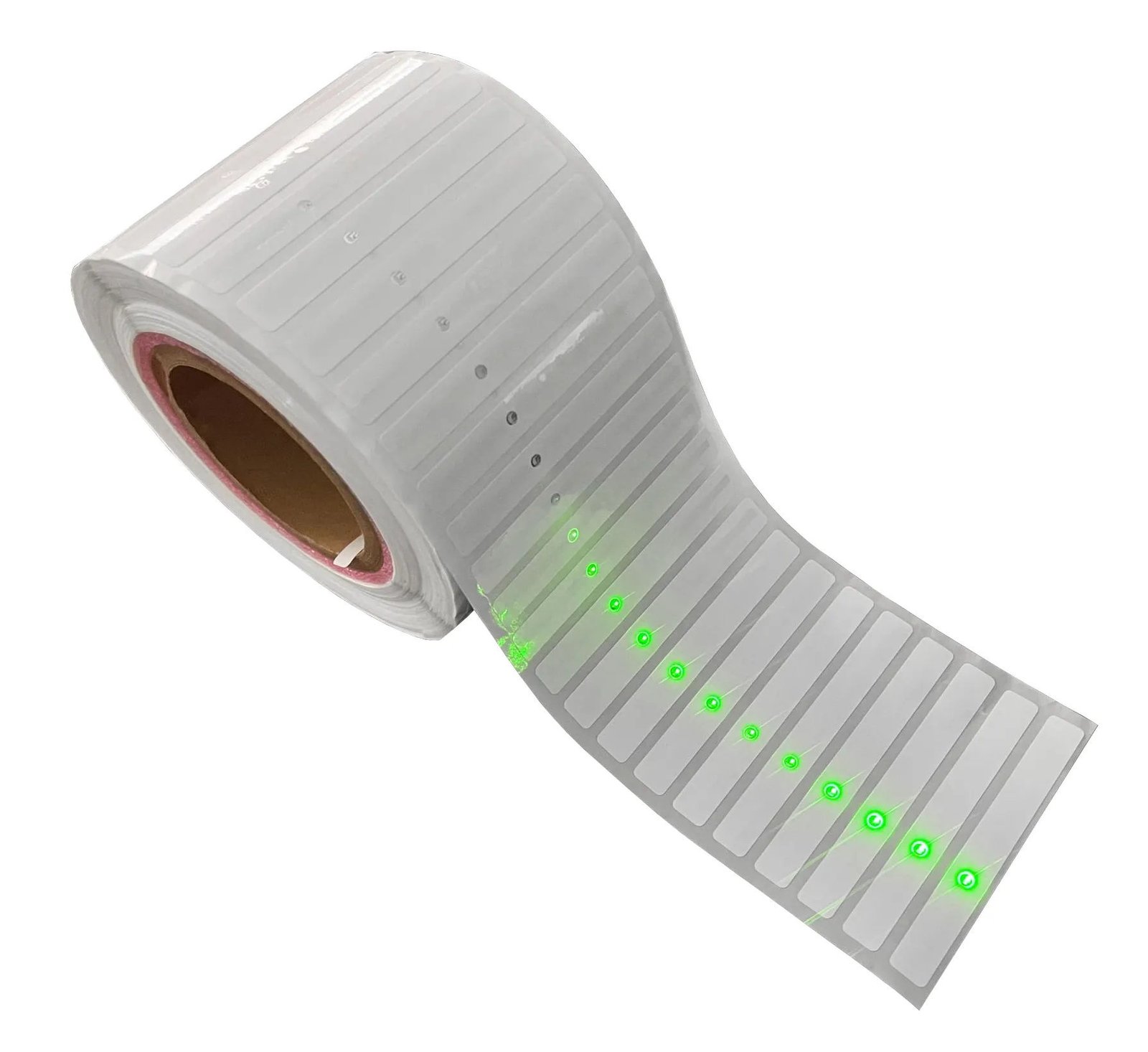

Rewritable & Reusable – Ideal for long-term industrial asset tracking.

-

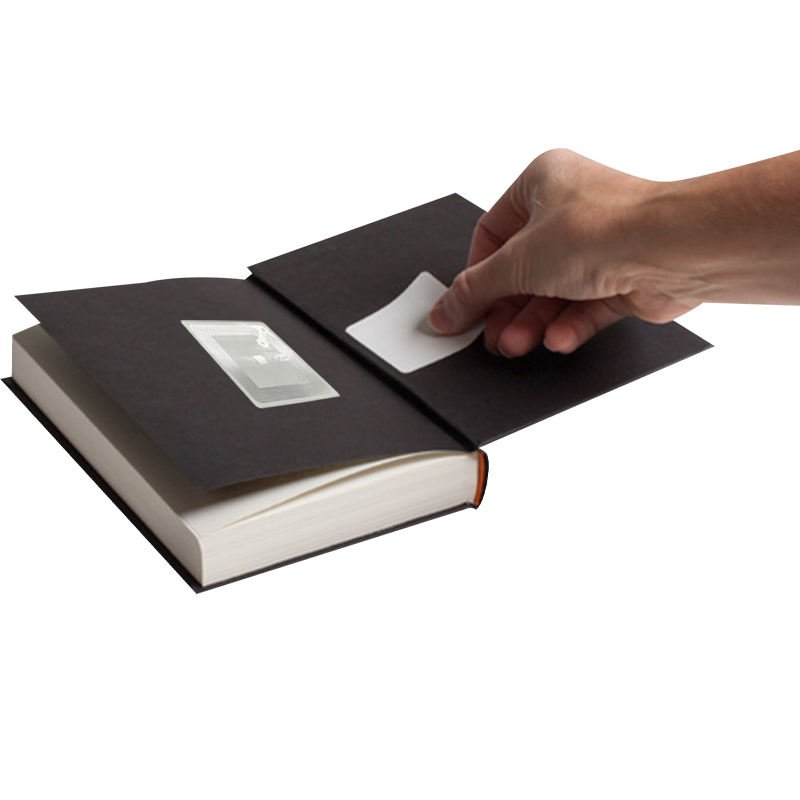

Flexible Mounting Options – Can be fixed with screws, rivets, or adhesive.

-

Customizable Encoding – EPC, user memory, and serial numbering available.

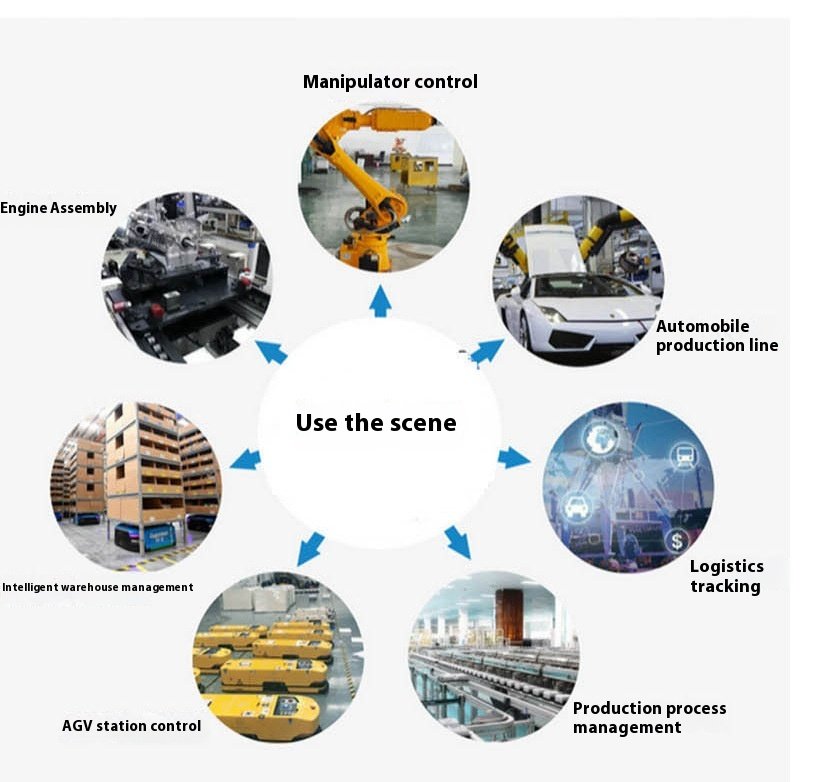

Application Scenarios

1. Manufacturing & Assembly Line Tracking

Industrial RFID tags are embedded into work carriers, pallets, and containers, ensuring that each component on an assembly line is accurately tracked. They allow factories to automate quality checks, record process steps, and reduce human error.

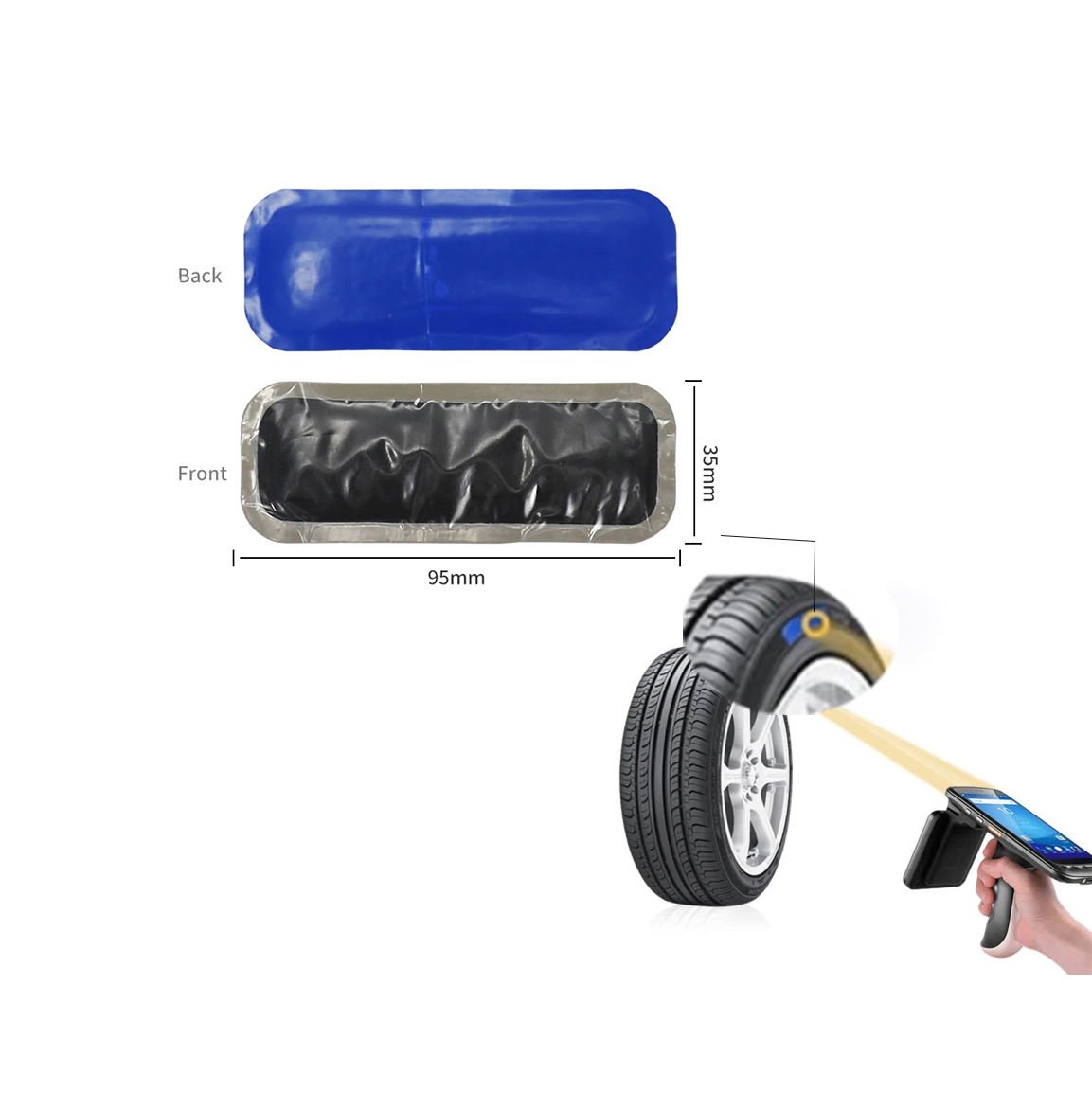

2. Automotive Industry Applications

In automobile manufacturing, RFID carrier tags withstand paint shops

3. Logistics & Supply Chain Management

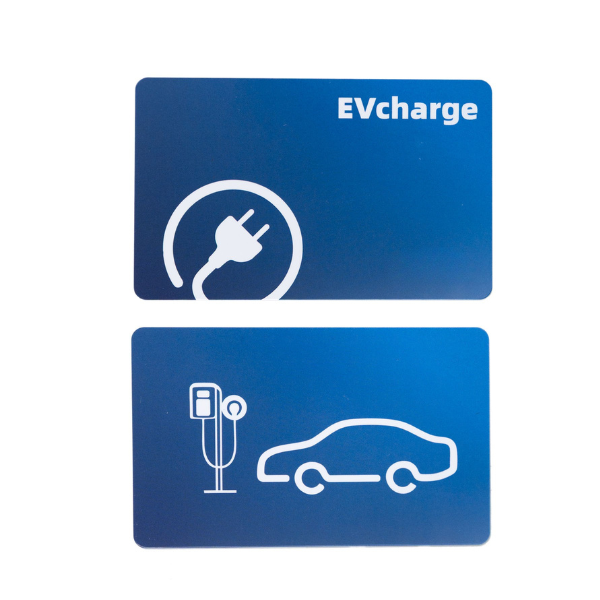

These UHF RFID tags enable real-time visibility of goods in warehouses and distribution centers. Pallets, containers, and industrial assets equipped with RFID tags provide automated inventory counts, theft prevention, and end-to-end supply chain transparency.

4. Chemical & Harsh Environments

Chemical plants and hazardous material handling facilities use RFID carrier tags that resist acid, alkali, oil, and solvents, ensuring safe and accurate asset identification in challenging settings.

5. Infrastructure & Landmark Management

Industrial UHF RFID tags are deployed in construction projects, power plants, and utility networks, serving as landmark identifiers for inspection and maintenance schedules.

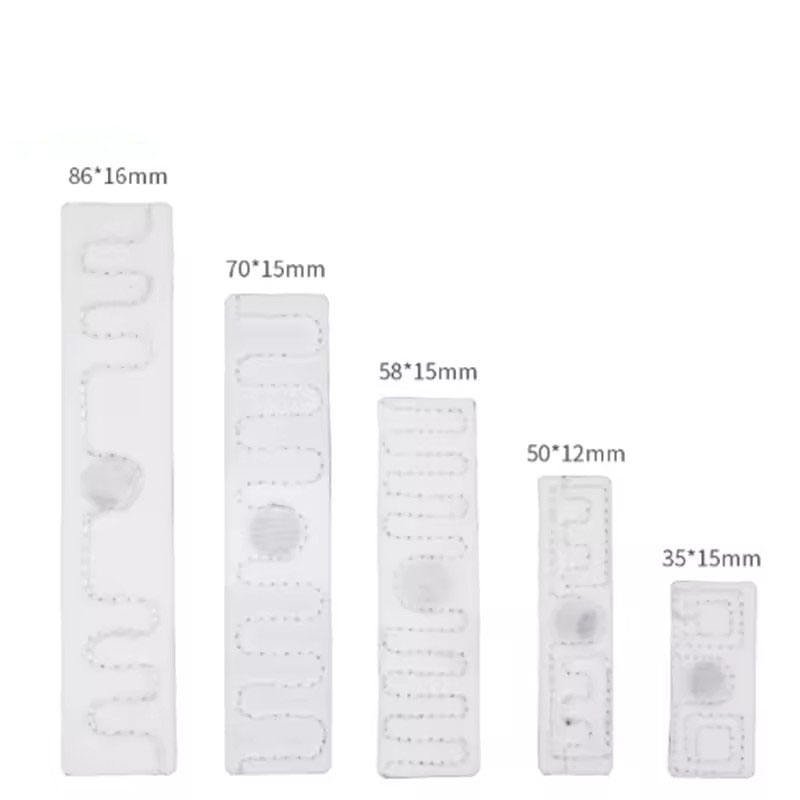

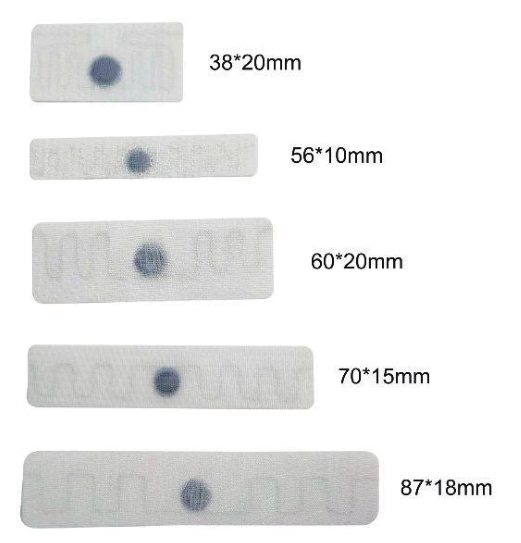

6. Laundry & Reusable Asset Tracking

For industries with reusable equipment (industrial uniforms, tools, containers), RFID tags withstand washing, sterilization, and high-pressure cleaning, supporting sustainable asset reuse.

Product Advantages

-

Extreme Durability – Withstands heat, water, and chemicals.

-

Long Read Range – Efficient for automated tracking in warehouses.

-

Operational Efficiency – Reduces manual scanning and paperwork.

-

High ROI – Reusable and reduces long-term operational costs.

-

Customizable – Can be encoded with serials, QR codes, or barcodes.

-

Global Standards Compliance – ISO18000-6C / EPC Gen2 for international compatibility.

Production Process

-

Material Preparation – PPS housing molded with industrial-grade precision.

-

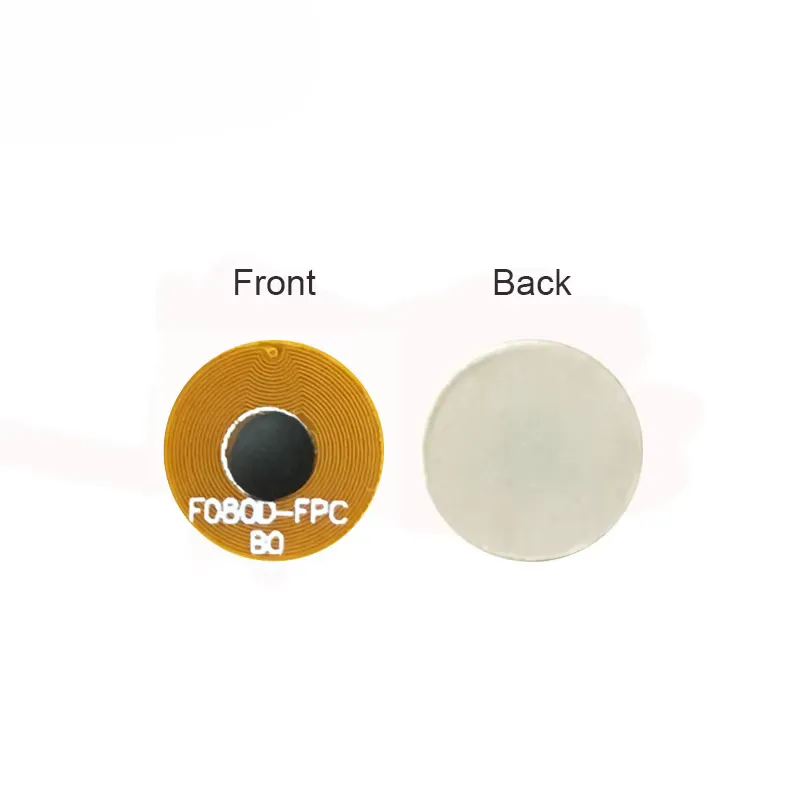

Chip Integration – UHF RFID chip embedded into encapsulation.

-

Antenna Design – Optimized for long-distance, anti-collision performance.

-

Sealing & Assembly – Ensures IP68 waterproof and dustproof rating.

-

Encoding & Testing – EPC numbers written, memory tested for reliability.

-

Final Quality Control – Verified under simulated industrial conditions.

Specifications

| Parameter | Value |

|---|---|

| Material | PPS (Polyphenylene Sulfide) |

| Frequency | 860–960 MHz (UHF, EPC Gen2 / ISO18000-6C) |

| Chip Options | Impinj Monza, Alien Higgs, NXP UCODE |

| Memory | EPC 96–512 bits, User memory up to 2KB |

| Read Range | 1 – 10 meters (depending on reader & environment) |

| Temperature Resistance | -40°C to +200°C |

| Waterproof Rating | IP68 |

| Mounting Options | Screws, rivets, adhesive |

| Applications | Manufacturing, logistics, automotive, chemical industry, infrastructure |

| Durability | High resistance to chemicals, oils, and solvents |

FAQ

Q1: Can these RFID tags survive industrial ovens and paint curing processes?

A1: Yes, they can withstand up to 200°C for short durations, making them suitable for automotive paint shops.

Q2: Are industrial UHF RFID tags reusable?

A2: Yes, they are designed for long-term industrial use and can be rewritten multiple times.

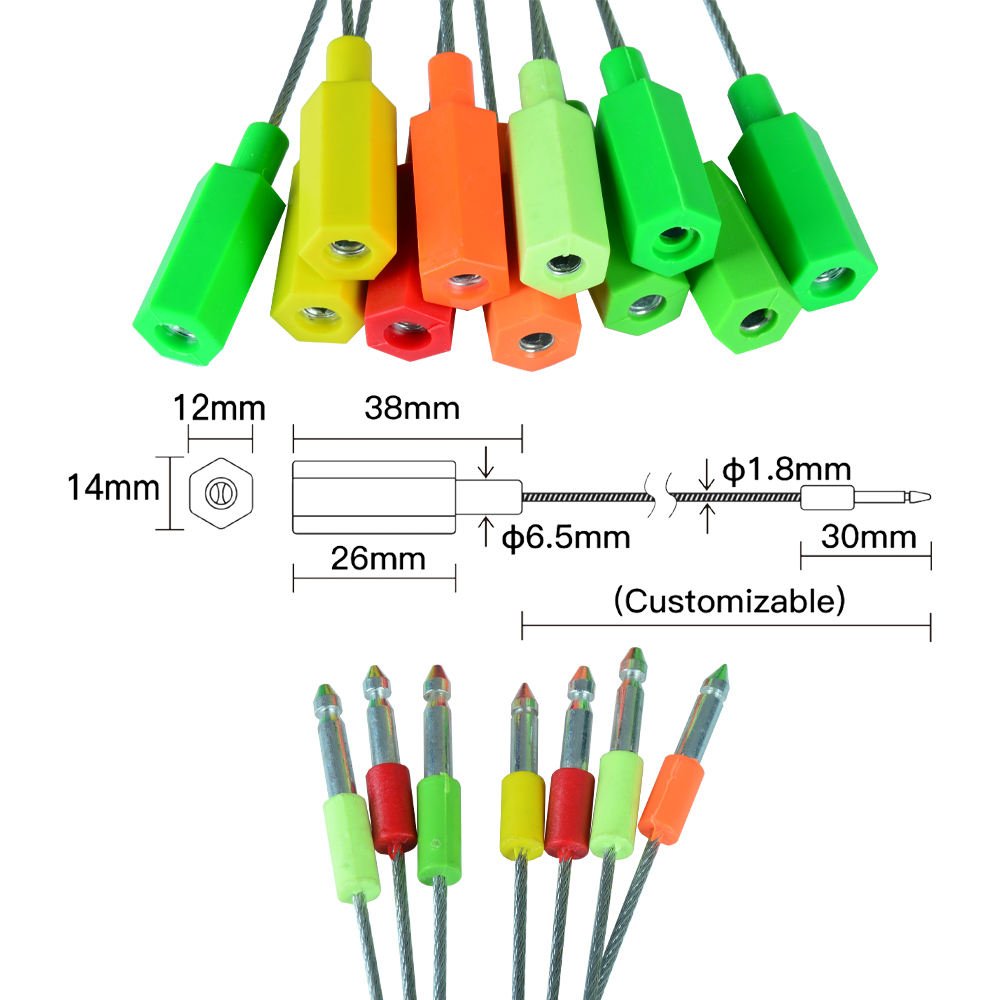

Q3: How are these tags attached to assets?

A3: They support screws, rivets, adhesives, or embedded mounting.

Q4: Can the tags work in chemical plants?

A4: Yes, PPS material provides resistance against oil, acid, alkali, and solvents.

Q5: Are they compatible with global RFID readers?

A5: Yes, they comply with ISO18000-6C and EPC Gen2 standards.