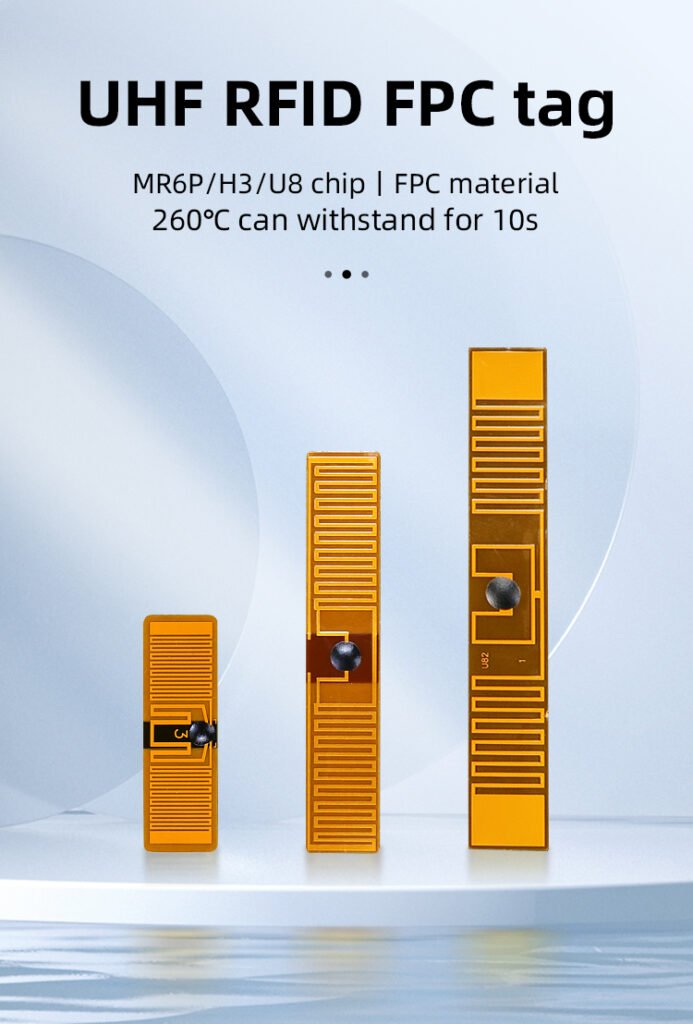

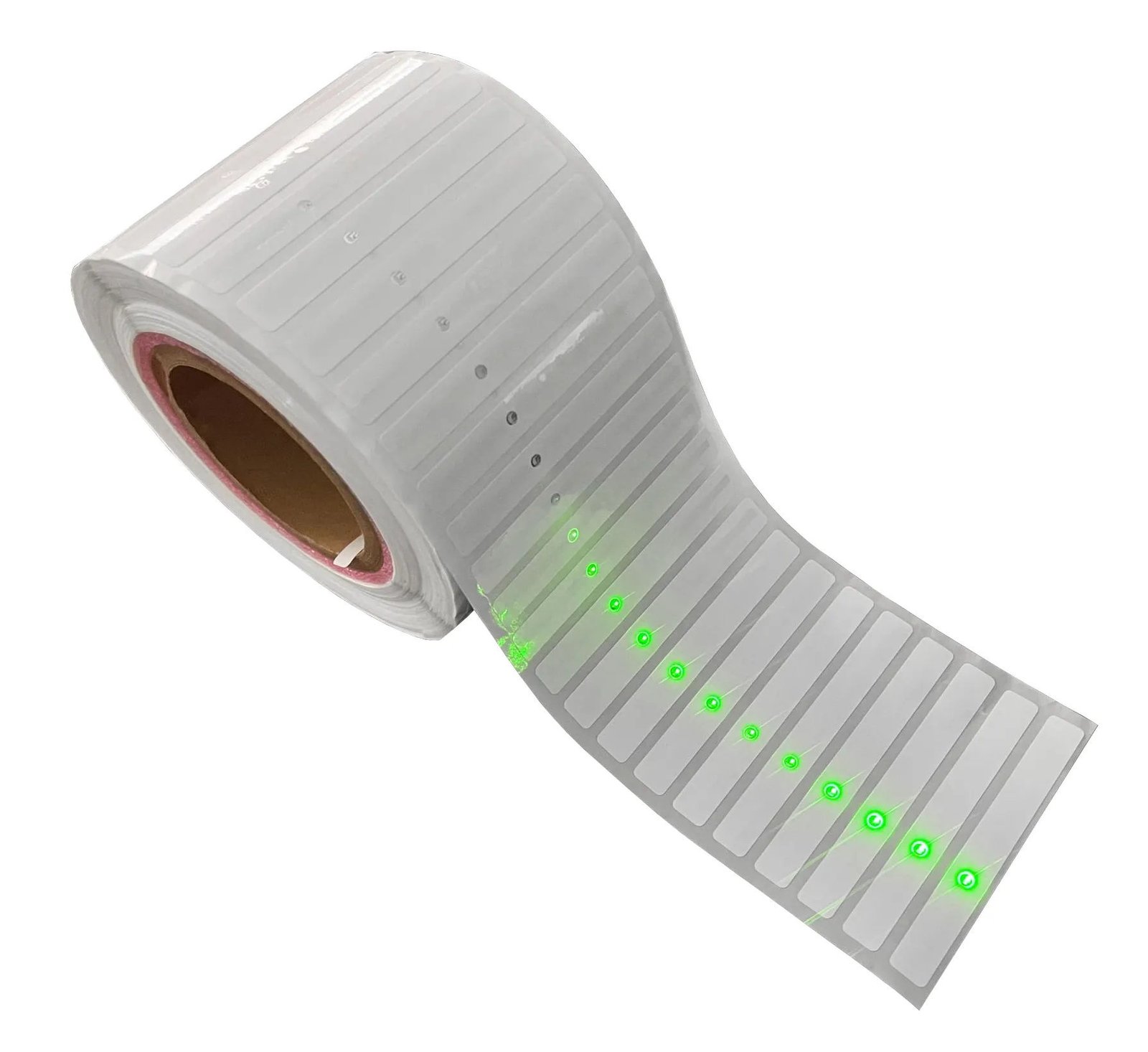

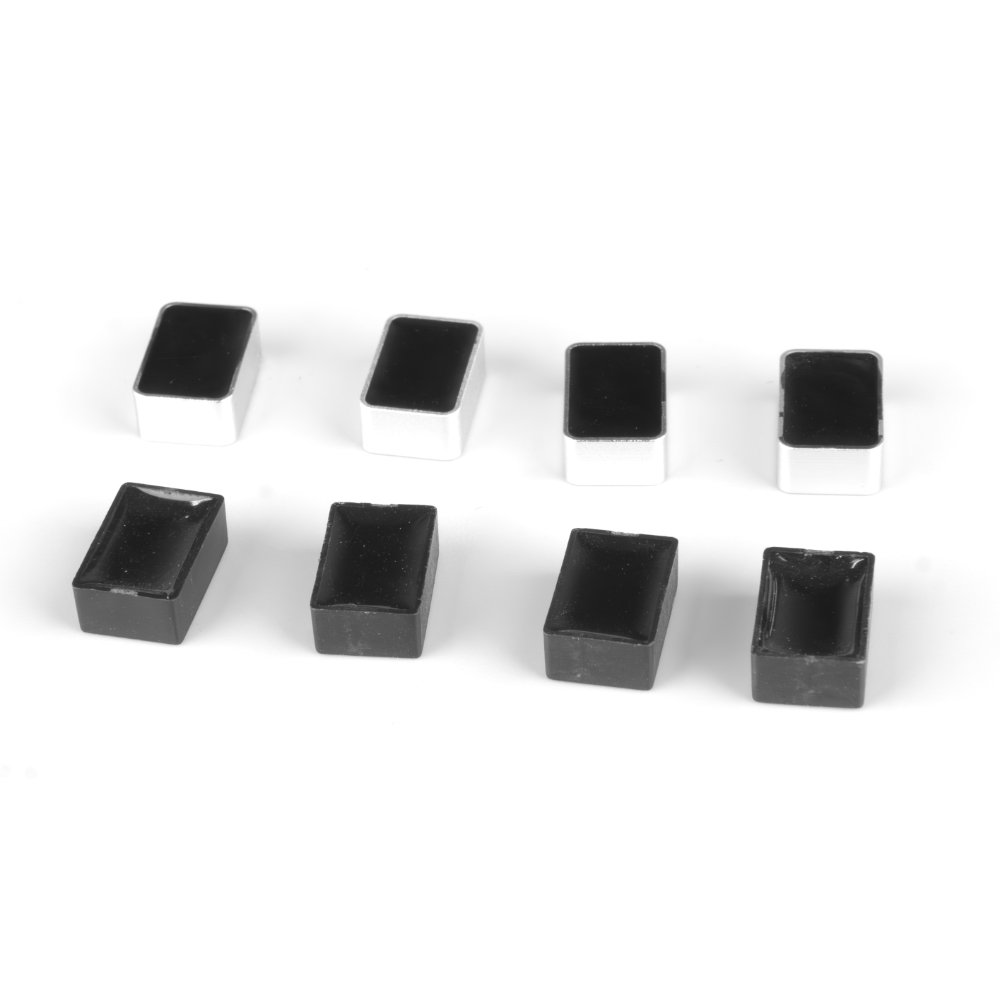

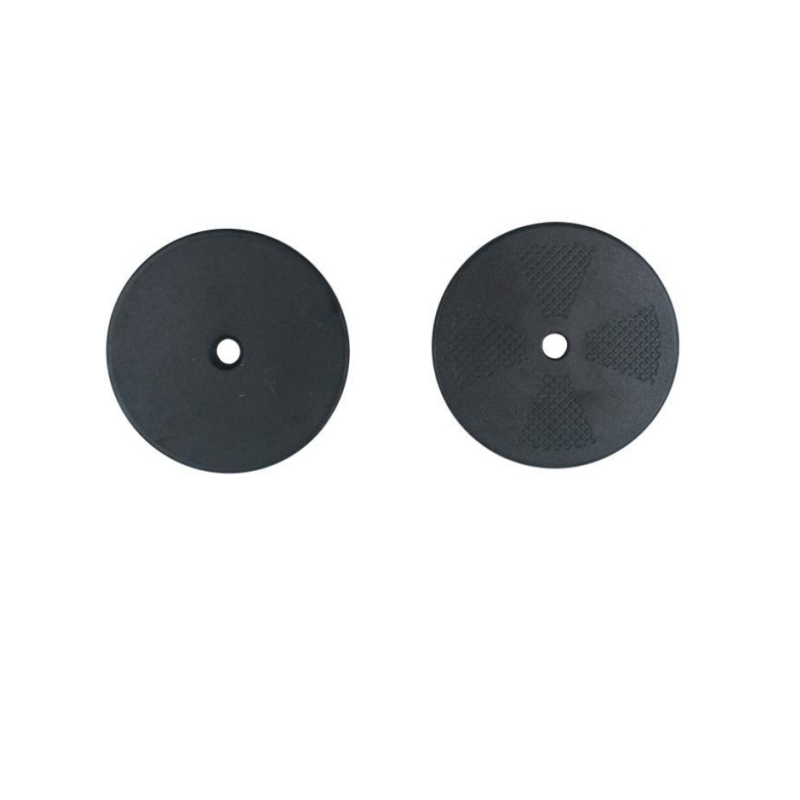

Flexible High-Temperature Resistant UHF RFID Tag – Passive FPC Corrosion-Resistant Label

1. Introduction: Flexible RFID Tag for Harsh Industrial Environments

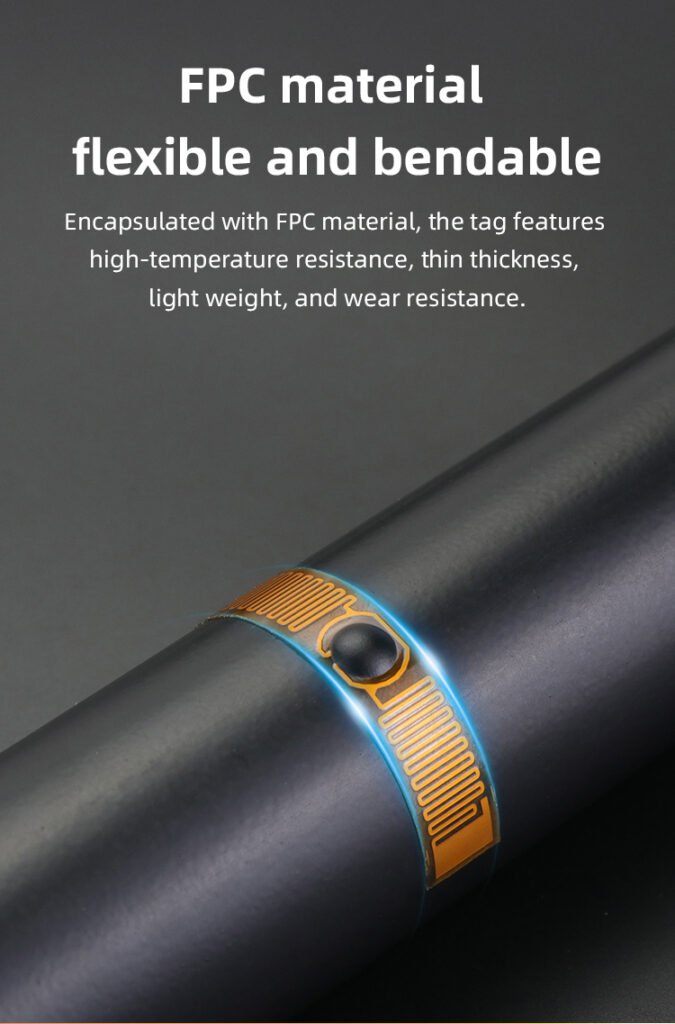

Modern industries such as manufacturing, automotive, logistics, and energy require RFID tags that can withstand heat, corrosion, and demanding conditions. The Wyuan Flexible High-Temperature Resistant UHF RFID Tag is built with FPC (Flexible Printed Circuit) material, making it lightweight, bendable, and highly durable.

With 860–960MHz UHF performance, this passive RFID tag delivers long-range readability, excellent signal stability, and strong resistance to high temperatures and chemicals. Its flexible design makes it ideal for applications on curved or irregular surfaces, while its corrosion resistance ensures long-term performance in harsh environments.

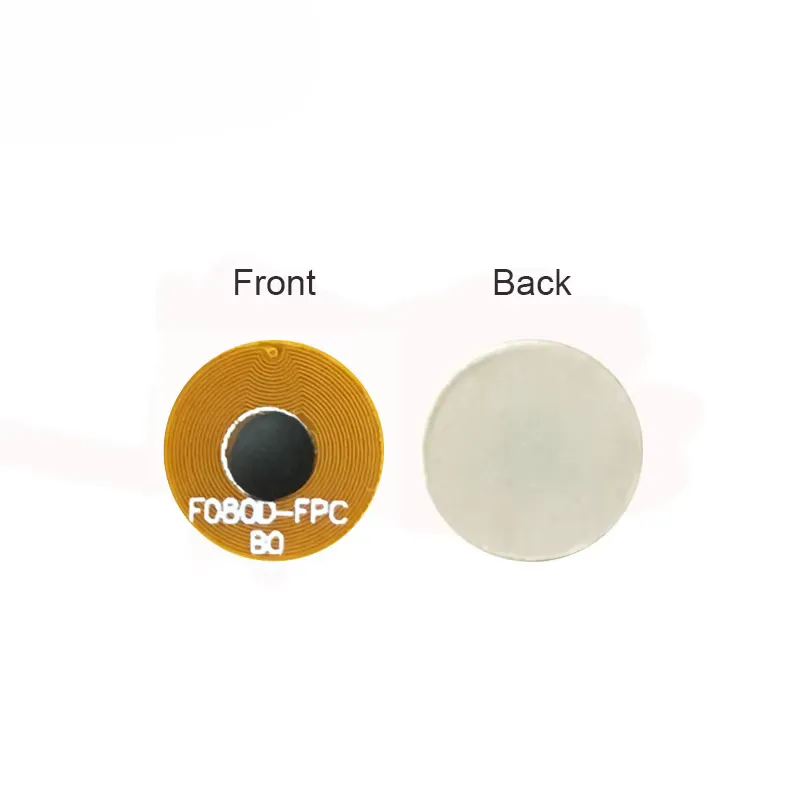

2. What is an FPC UHF RFID Tag?

An FPC-based RFID tag uses a flexible printed circuit substrate to achieve:

-

Slim and bendable form factor for non-flat surfaces.

-

Durability against heat and corrosion in industrial settings.

-

Passive UHF RFID performance without a battery.

This makes it suitable for asset tracking, industrial automation, and supply chain visibility where standard rigid tags may fail.

3. Key Features

-

Flexible FPC Material

-

Ultra-thin and bendable for curved surfaces.

-

Lightweight and easy to integrate.

-

-

High-Temperature Resistant

-

Withstands temperatures up to +200°C.

-

Suitable for automotive, electronics, and industrial processes.

-

-

Corrosion-Resistant Design

-

Protected against chemicals, humidity, and oxidation.

-

Ensures reliability in outdoor or harsh conditions.

-

-

Long-Range UHF Readability

-

Frequency 860–960MHz.

-

EPC Gen2 / ISO18000-6C compliant.

-

Read range up to 3–6 meters.

-

-

Customizable Printing & Encoding

-

Logos, barcodes, QR codes, and serials supported.

-

Multiple chip options for different memory sizes.

-

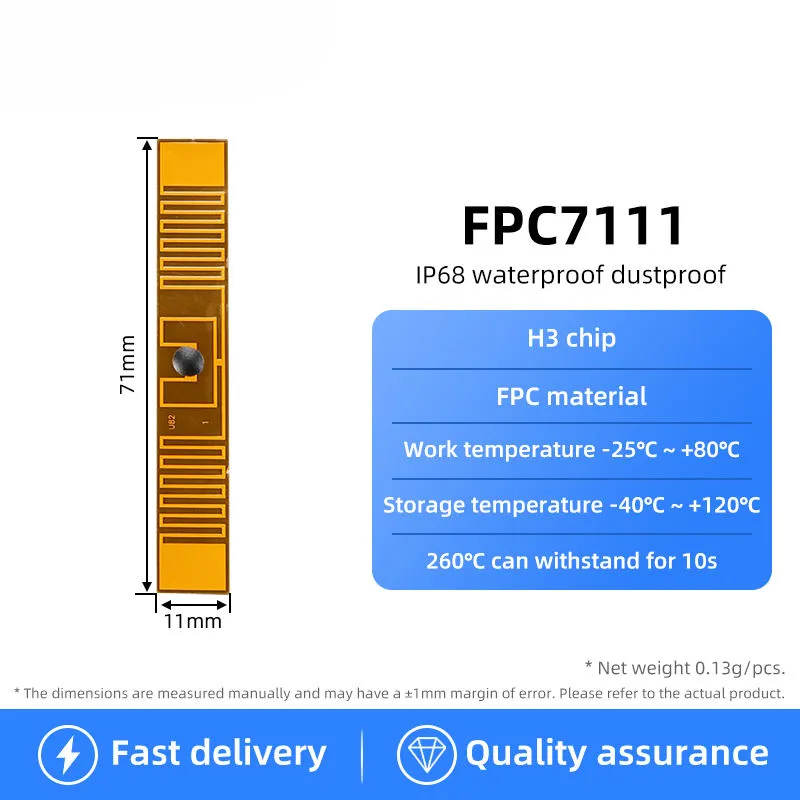

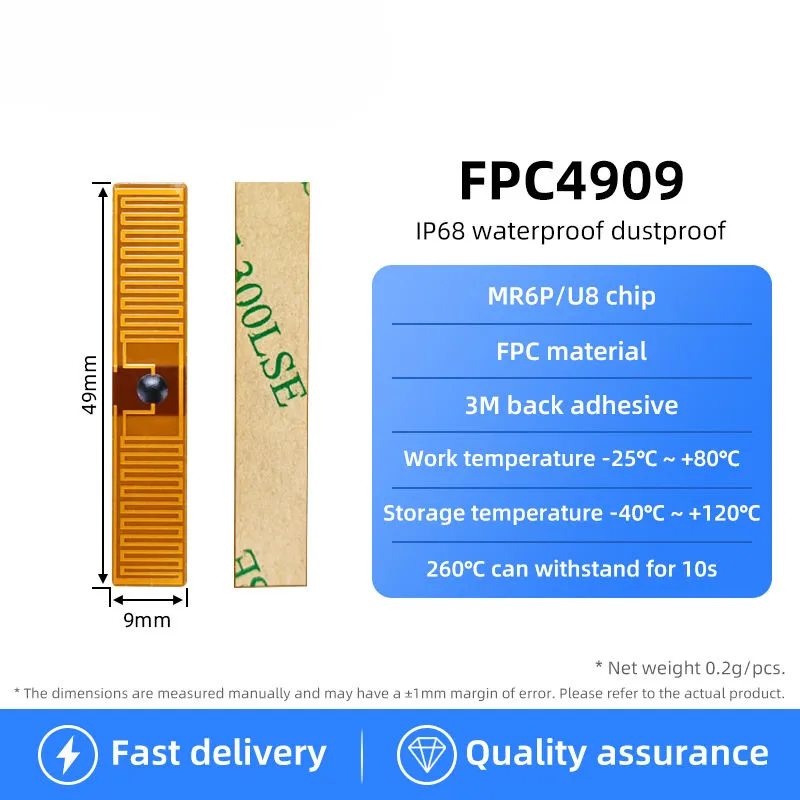

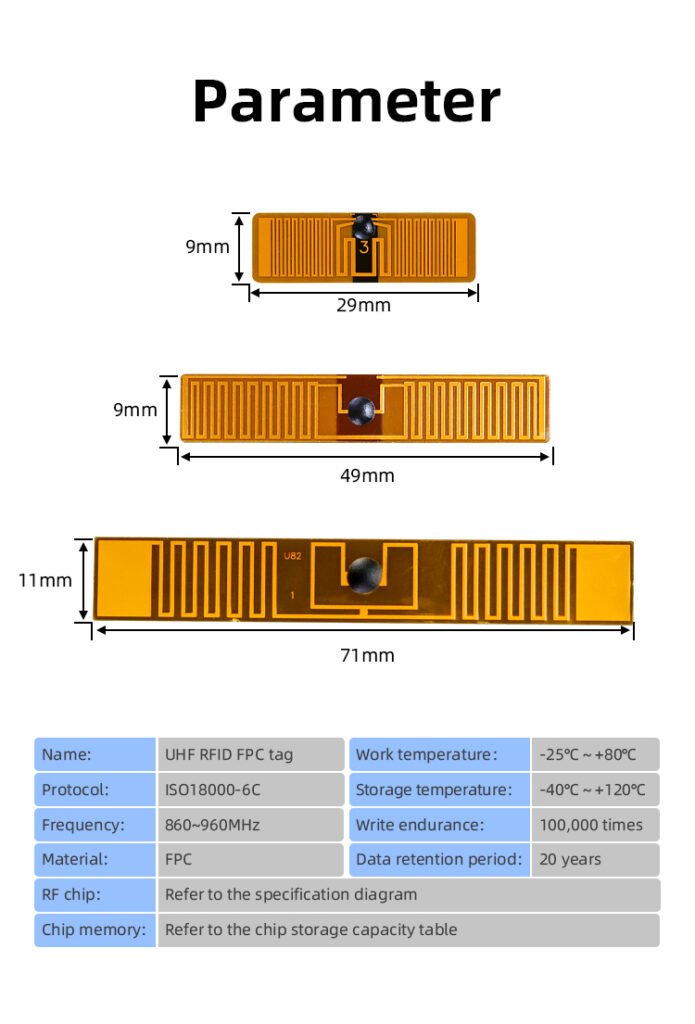

4. Technical Specifications

| Parameter | Details |

|---|---|

| Frequency Range | 860–960MHz (UHF RFID) |

| Protocols | EPCglobal Class 1 Gen2 / ISO18000-6C |

| Material | FPC (Flexible Printed Circuit) |

| Read Range | 3–6 meters |

| Temperature Range | -40°C to +200°C |

| Corrosion Resistance | Resistant to chemicals, oxidation, and humidity |

| Chip Options | Impinj Monza, NXP UCODE, Alien Higgs |

| Printing Options | Logo, barcode, QR code, serial number |

| Applications | Automotive, electronics, logistics, manufacturing, asset tracking |

5. Advantages Over Standard RFID Tags

-

Flexible & thin – adapts to curved or irregular surfaces.

-

Heat resistant – operates in high-temperature environments.

-

Corrosion-proof – suitable for outdoor and industrial use.

-

Long-range readability – efficient bulk scanning.

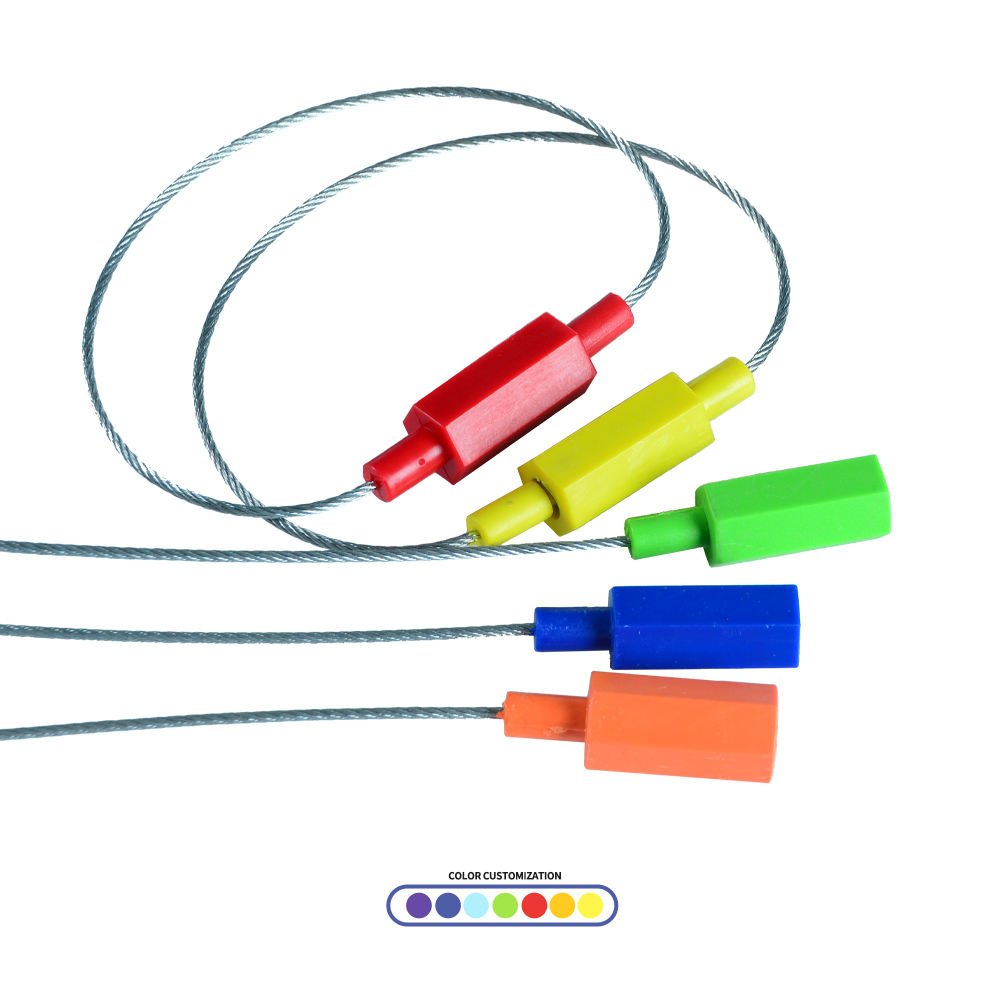

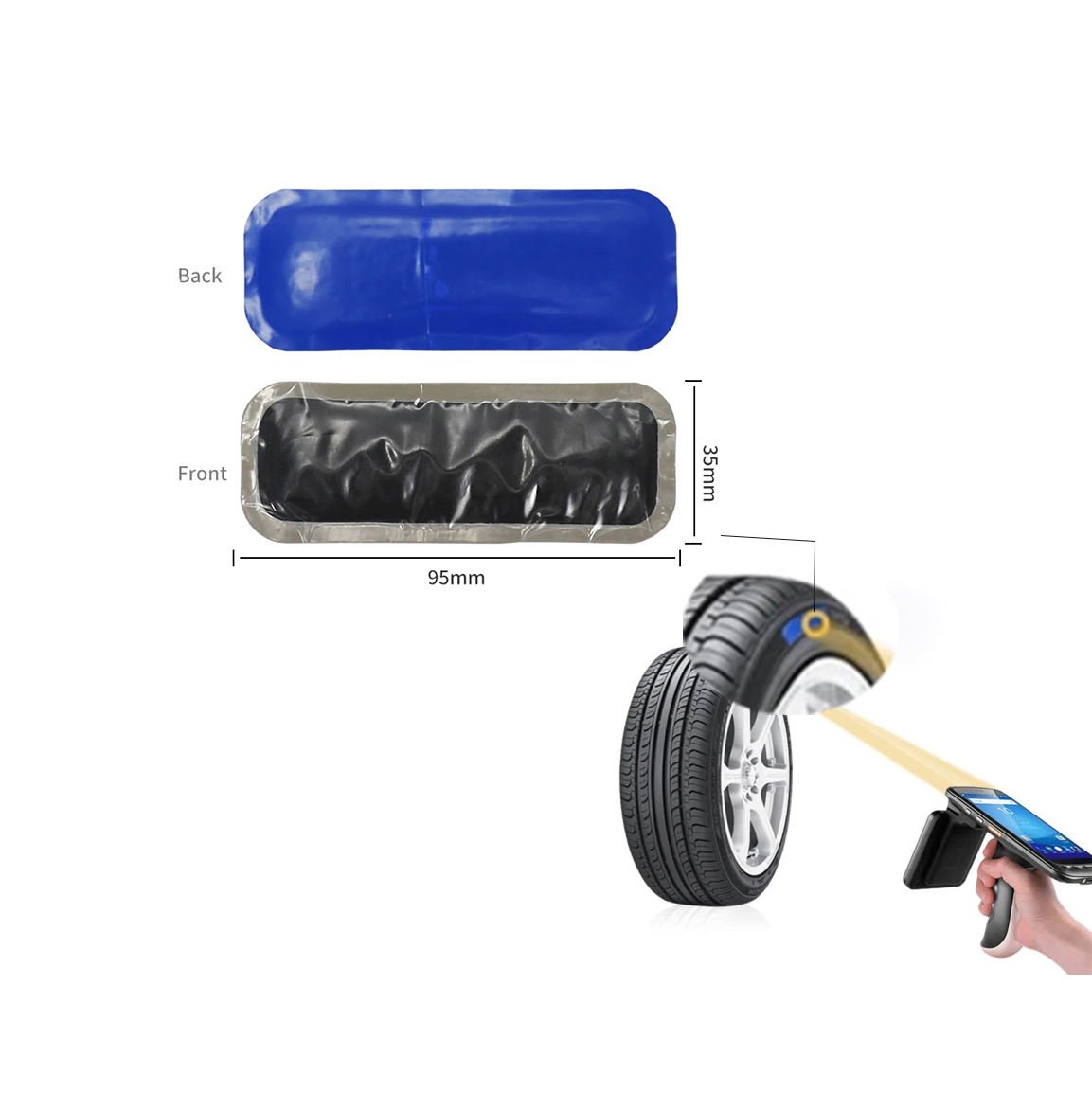

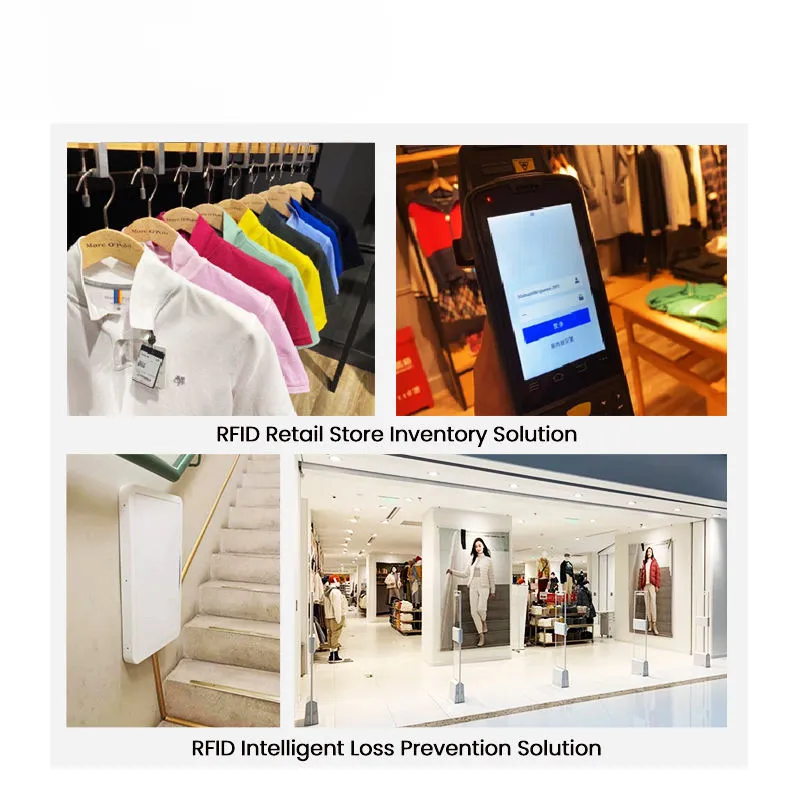

6. Applications

-

Automotive – parts tracking, tire and battery monitoring.

-

Electronics – high-temp component identification.

-

Industrial Manufacturing – machinery, tools, and WIP tracking.

-

Logistics & Supply Chain – durable tracking in harsh conditions.

-

Energy & Utilities – corrosion-resistant tracking for pipelines and equipment.

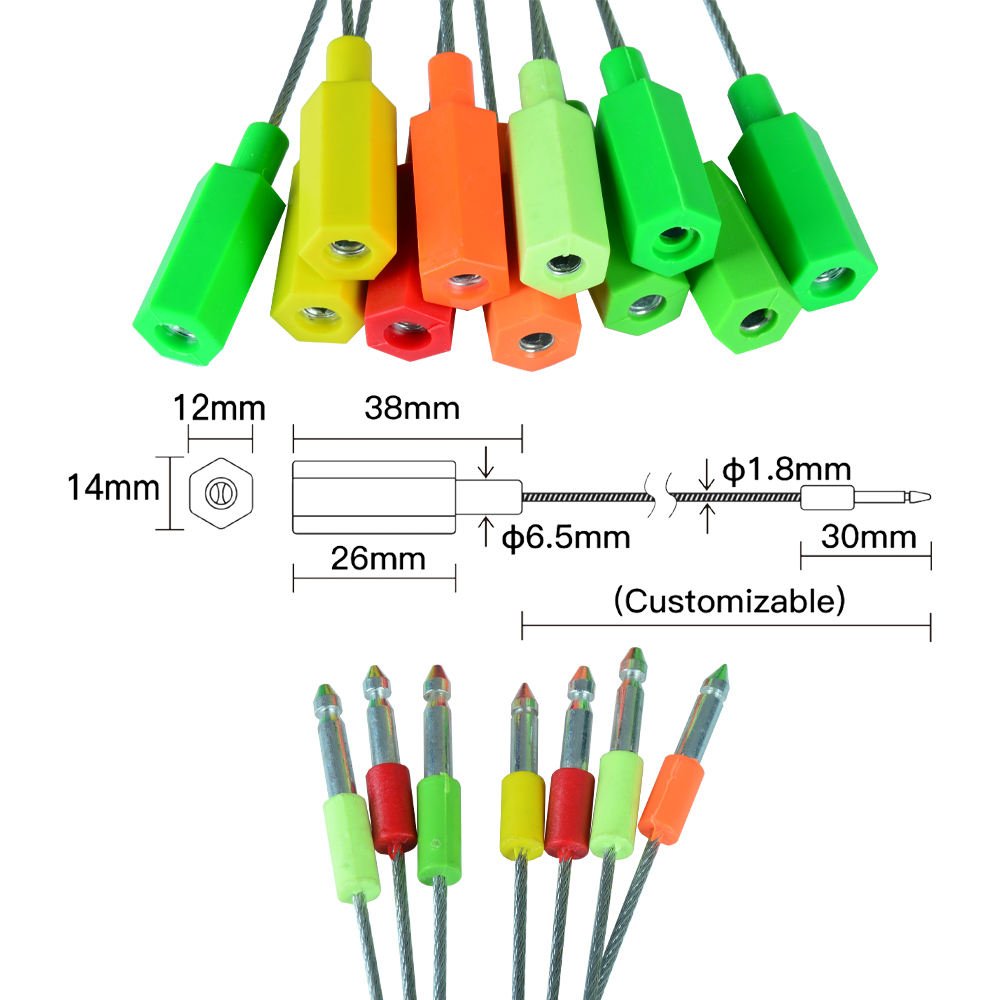

7. Customization Options

-

Chip memory capacity and encryption.

-

Printing with logo, QR code, or barcode.

-

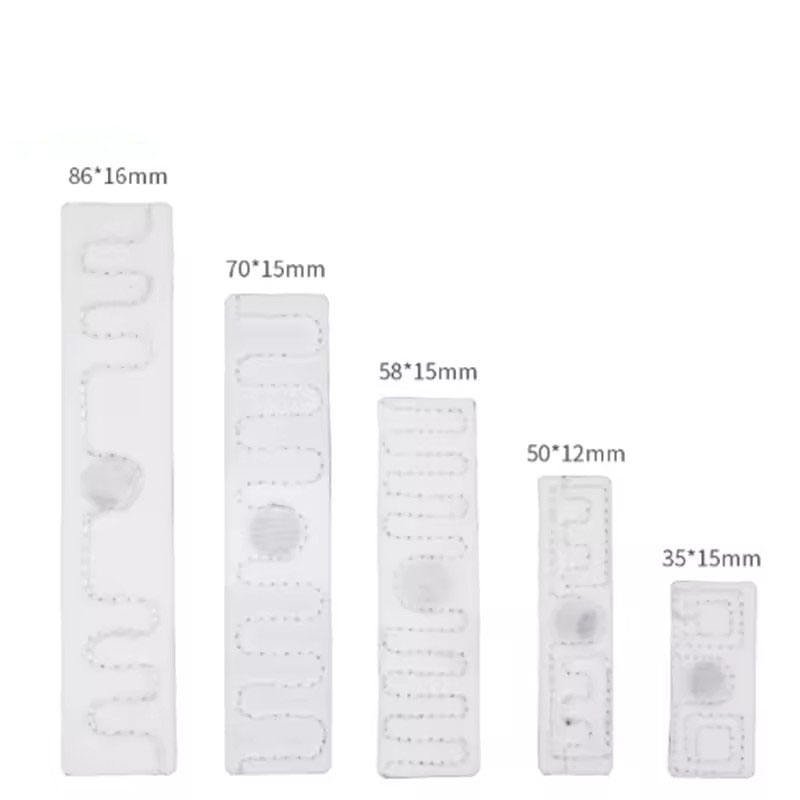

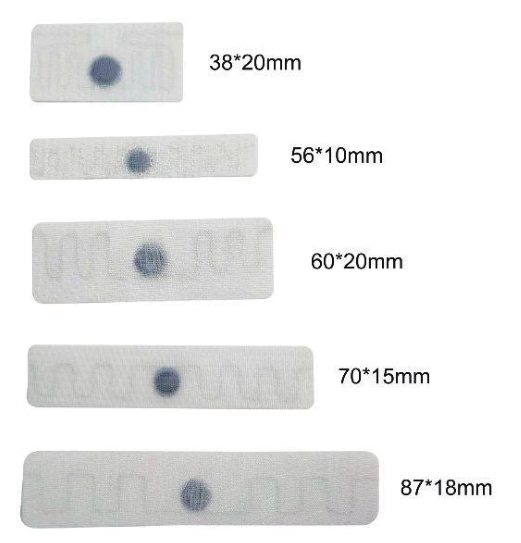

Custom dimensions and adhesive backing.

-

Pre-encoding for fast deployment.

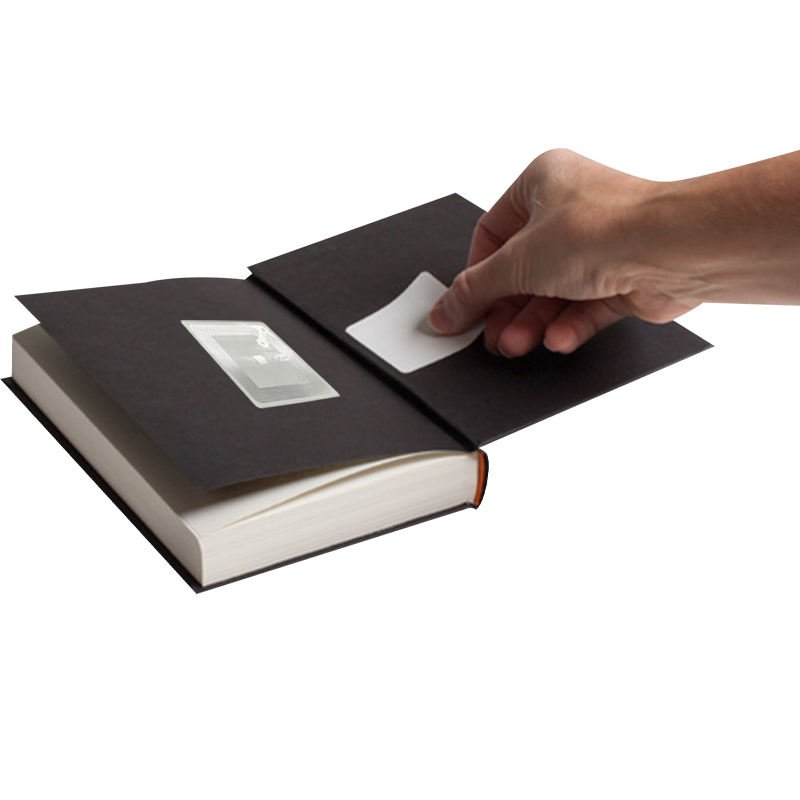

8. Installation & Deployment

-

Apply the flexible RFID tag on curved or flat surfaces.

-

Encode the chip with unique ID or tracking data.

-

Use UHF RFID readers for real-time scanning.

-

Integrate with ERP, WMS, or IoT platforms.

9. Frequently Asked Questions (FAQ)

Q1: Can this tag be used outdoors?

Yes, it is corrosion-resistant and durable in harsh outdoor conditions.

Q2: What is the maximum temperature tolerance?

Up to +200°C depending on application.

Q3: Can it be applied to curved surfaces?

Yes, the FPC flexible material allows bending and slim fitting.

Q4: What is the read range?

3–6 meters, depending on the reader and environment.

Q5: Which industries benefit most?

Automotive, electronics, manufacturing, energy, and logistics.

10. Conclusion

The Flexible High-Temperature Resistant UHF RFID Tag is a reliable, durable, and flexible RFID solution for industries needing heat-resistant, corrosion-proof, and long-range RFID performance. Its FPC construction ensures adaptability on curved surfaces, making it ideal for automotive, industrial, and logistics applications.