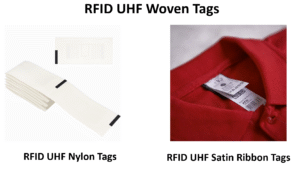

Summary: RFID Woven Labels—The Invisible Foundation of Apparel Digitization

This article explains how RFID Woven Labels are replacing traditional hangtags to become the essential tool for “item-level digital management” in the fashion industry.

Technical Superiority: The article highlights how RFID outperforms barcodes through non-line-of-sight reading, bulk processing, and unique identification. It confirms UHF (Ultra-High Frequency) as the industry standard due to its long range and high speed.

Solving Key Pain Points: Unlike stickers or hangtags that fall off or get swapped, woven labels are sewn directly into the garment. This eliminates “ghost inventory” and creates a permanent digital defense against counterfeiting.

Full Lifecycle Efficiency: It details the entire digital loop, from factory encoding and safe sewing techniques to warehouse “tunnel” scanning and smart retail checkouts.

Cost vs. Value: While the unit price is higher than paper tags, woven labels save money by removing manual tagging labor and increasing inventory accuracy from 70% to 99%.

Implementation Guide: The article provides a “pitfall avoidance” guide for production (avoiding high-heat ironing) and warehousing (managing metal interference). It also offers a checklist for project launches, emphasizing top-down management consensus.