Industry 4.0 RFID Tag – High-Frequency 30mm Industrial Code Carrier for Automation, Smart Factory, and Manufacturing Execution Systems (MES)

Product Overview

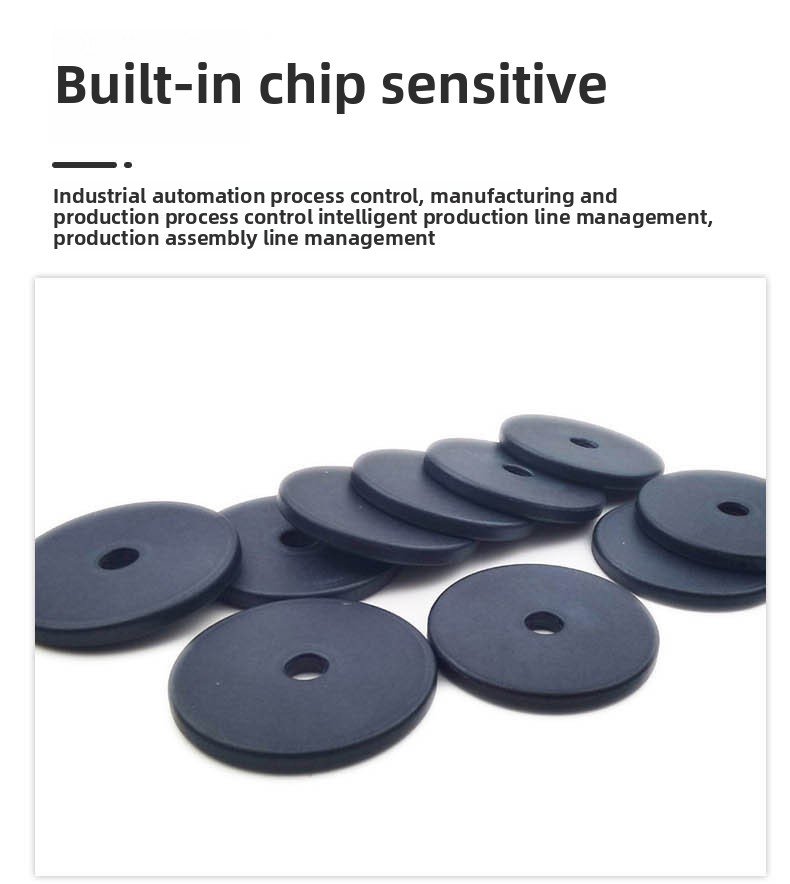

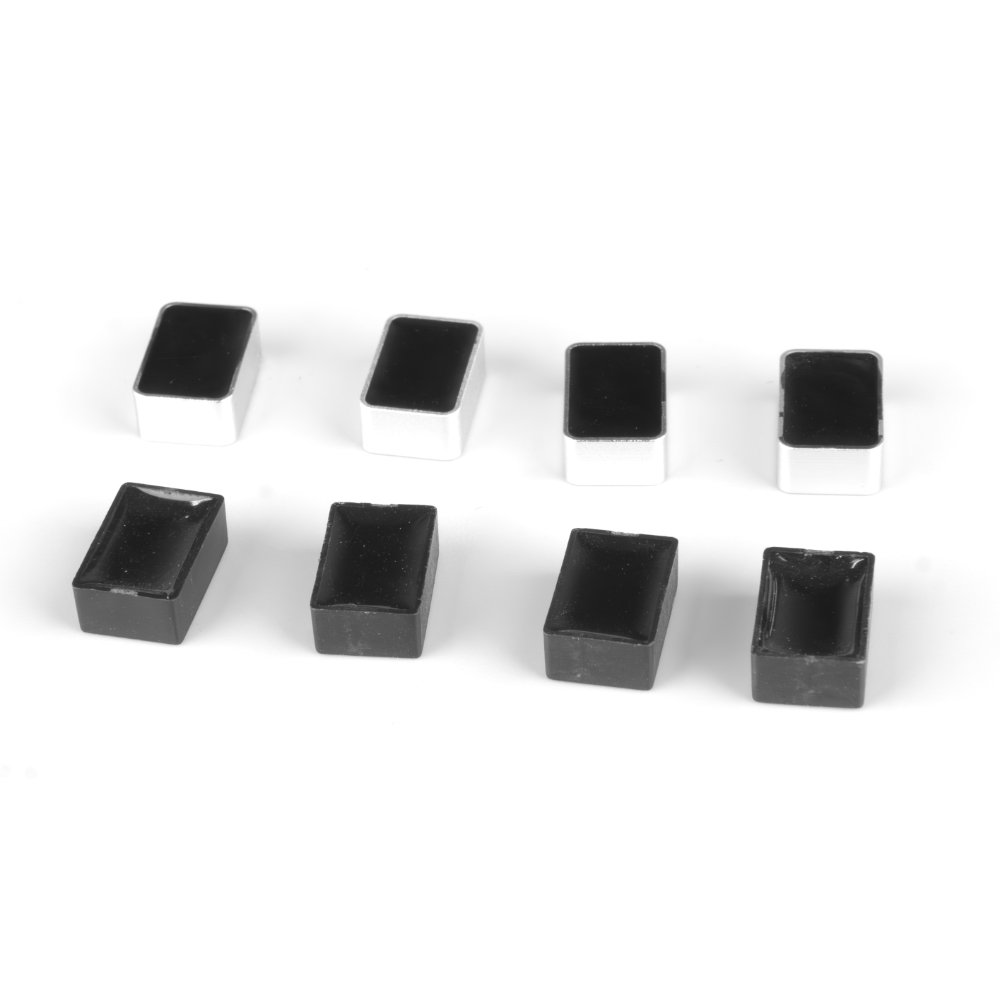

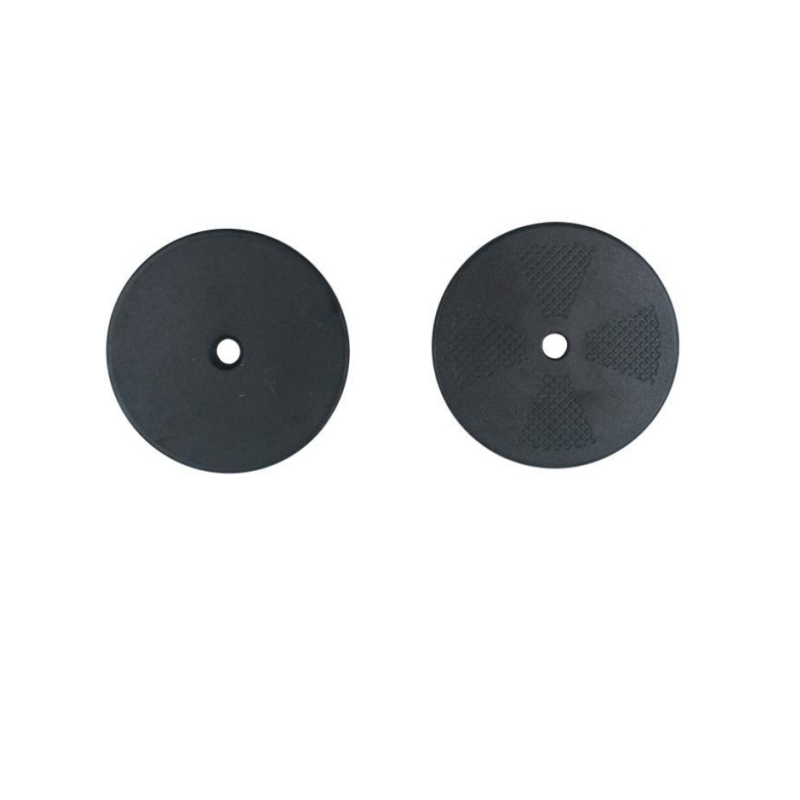

The Industry 4.0 RFID Tag (30mm High-Frequency Industrial Code Carrier) is designed for modern industrial automation environments, enabling seamless integration into smart factories, automated production lines, and real-time asset tracking systems.

Built with high-frequency (13.56 MHz) RFID technology, these tags are fully compliant with ISO15693 / ISO14443 standards, supporting fast data exchange, secure communication, and integration with Manufacturing Execution Systems (MES), ERP software, and robotic automation platforms.

Encapsulated in high-strength industrial-grade housing, the tag withstands mechanical stress, water, oil, and high temperatures, making it ideal for continuous use in harsh environments such as metal processing, electronics assembly, automotive manufacturing, and warehouse automation.

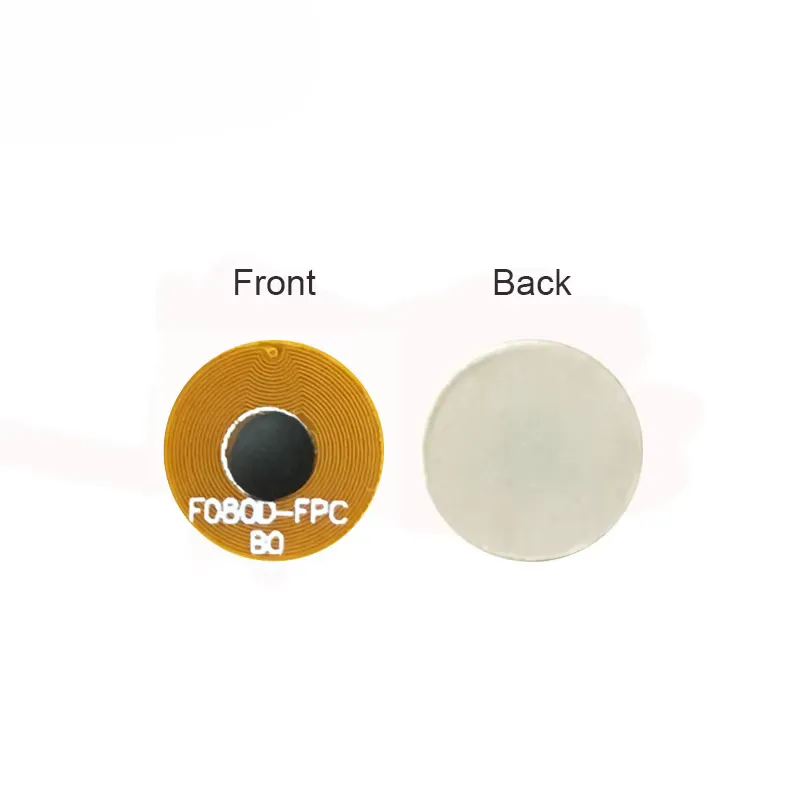

With a compact 30mm diameter, the RFID code carrier is easy to embed into fixtures, pallets, jigs, and industrial carriers, providing each asset with a unique digital identity for accurate tracking throughout its lifecycle.

Key Features

-

Industry 4.0 Ready – Fully supports integration with MES, ERP, and IoT platforms.

-

High-Frequency Operation (13.56 MHz) – Reliable, secure communication with industrial readers.

-

30mm Compact Size – Easy embedding into fixtures, pallets, or tools.

-

Durable Industrial Housing – Resistant to heat, water, oil, and shock.

-

Fast Data Encoding & Retrieval – Supports real-time process monitoring.

-

Customizable Encoding – EPC, serial numbering, and memory partitioning available.

-

Global Standards Compliance – ISO15693, ISO14443 for worldwide compatibility.

-

Reusable & Sustainable – Designed for long-term use across multiple cycles.

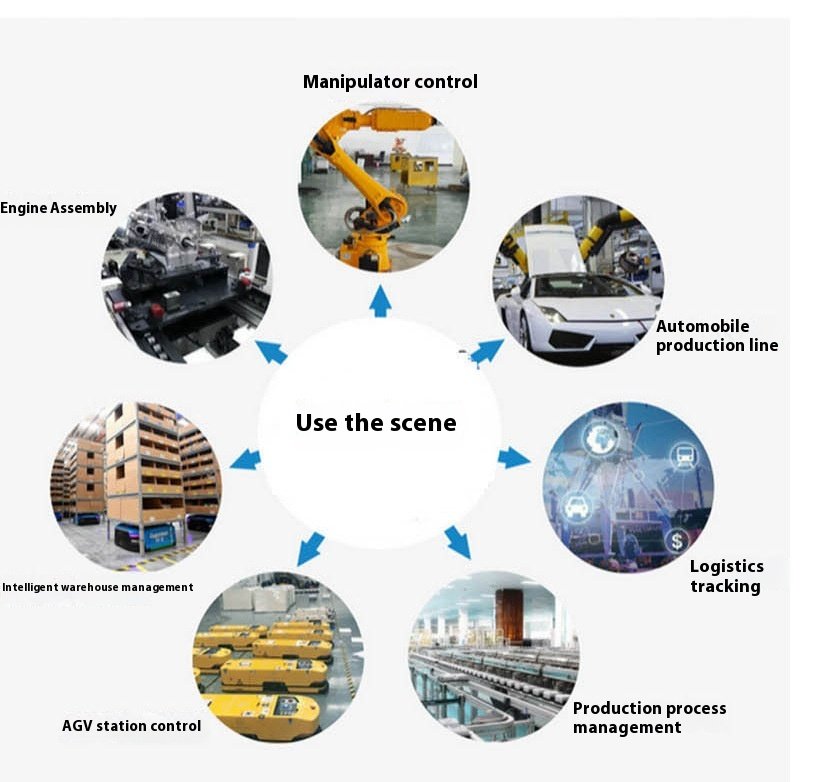

Application Scenarios

1. Smart Factory Automation

RFID tags act as digital code carriers for tools, parts, and machines, enabling real-time production scheduling, automated routing, and machine-to-machine communication.

-

Supports predictive maintenance by linking machine usage data with MES.

-

Ensures each part is tracked through every stage of production.

-

Reduces manual scanning, minimizing human errors.

2. Automotive & Electronics Assembly Lines

Each component on the production line is equipped with an RFID tag to enable traceability, quality control, and workflow automation.

-

Ensures accurate part identification and assembly validation.

-

Withstands exposure to oil, dust, and heat in automotive welding shops.

-

Facilitates just-in-time (JIT) inventory management.

3. Logistics & Warehouse Automation

RFID-enabled pallets and containers with industrial code carriers allow real-time inventory visibility and end-to-end supply chain monitoring.

-

Enhances warehouse picking accuracy with automated RFID scanning.

-

Improves stock management and reduces lost or misplaced assets.

-

Integrates seamlessly with WMS (Warehouse Management Systems).

4. Robotics & Industrial IoT Integration

Industrial RFID tags provide robots and AGVs (Automated Guided Vehicles) with precise location and task data, enabling autonomous navigation and task execution.

-

Facilitates robot-to-robot communication within smart factories.

-

Works with Industrial IoT sensors to build digital twins of production environments.

-

Enhances safety protocols by ensuring tools and materials are tracked at all times.

Product Advantages

-

Reliable Performance – Consistent reads even in harsh industrial settings.

-

Compact Design – 30mm diameter ideal for embedded use.

-

High Security – Supports encryption and anti-cloning for secure data storage.

-

Operational Efficiency – Reduces downtime with automated tracking.

-

Scalability – Easily integrated into large-scale Industry 4.0 ecosystems.

-

Sustainability – Reusable, reduces paper labeling and manual record-keeping.

Production Process

-

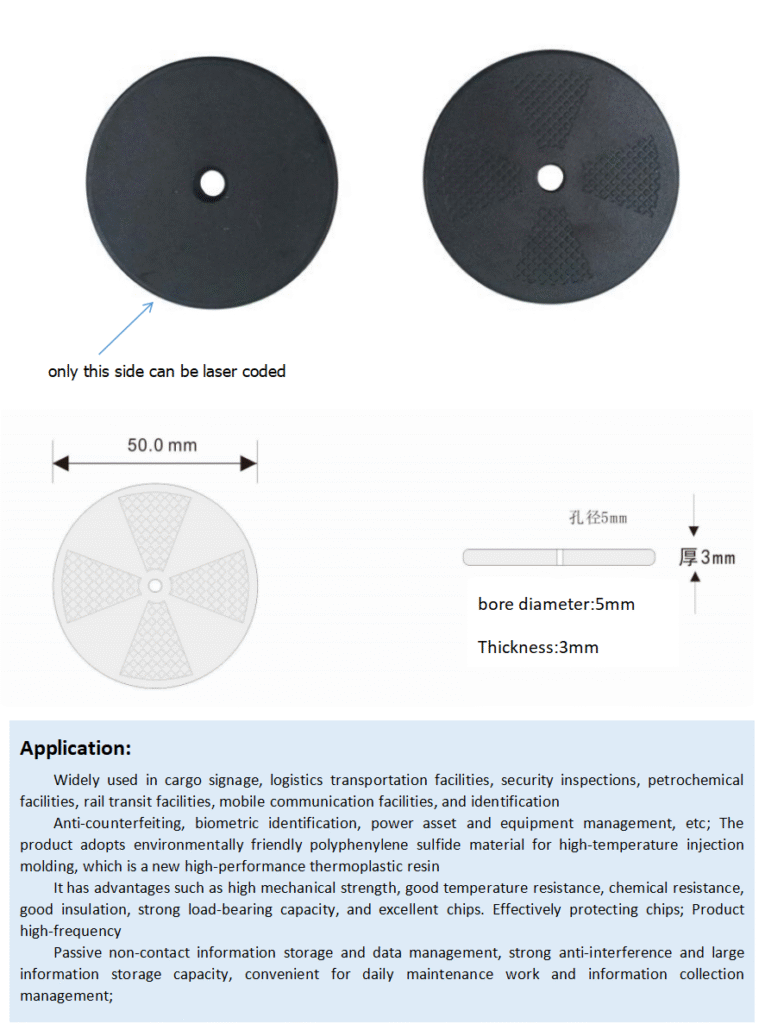

Material Selection – High-strength PPS/industrial resin chosen for durability.

-

Chip Integration – High-frequency RFID chip embedded with precision antenna.

-

Encapsulation – Housing molded to protect against oil, dust, and chemicals.

-

Signal Optimization – Antenna tuned for stable high-frequency communication.

-

Testing & Encoding – Each tag undergoes high-stress testing and EPC encoding.

-

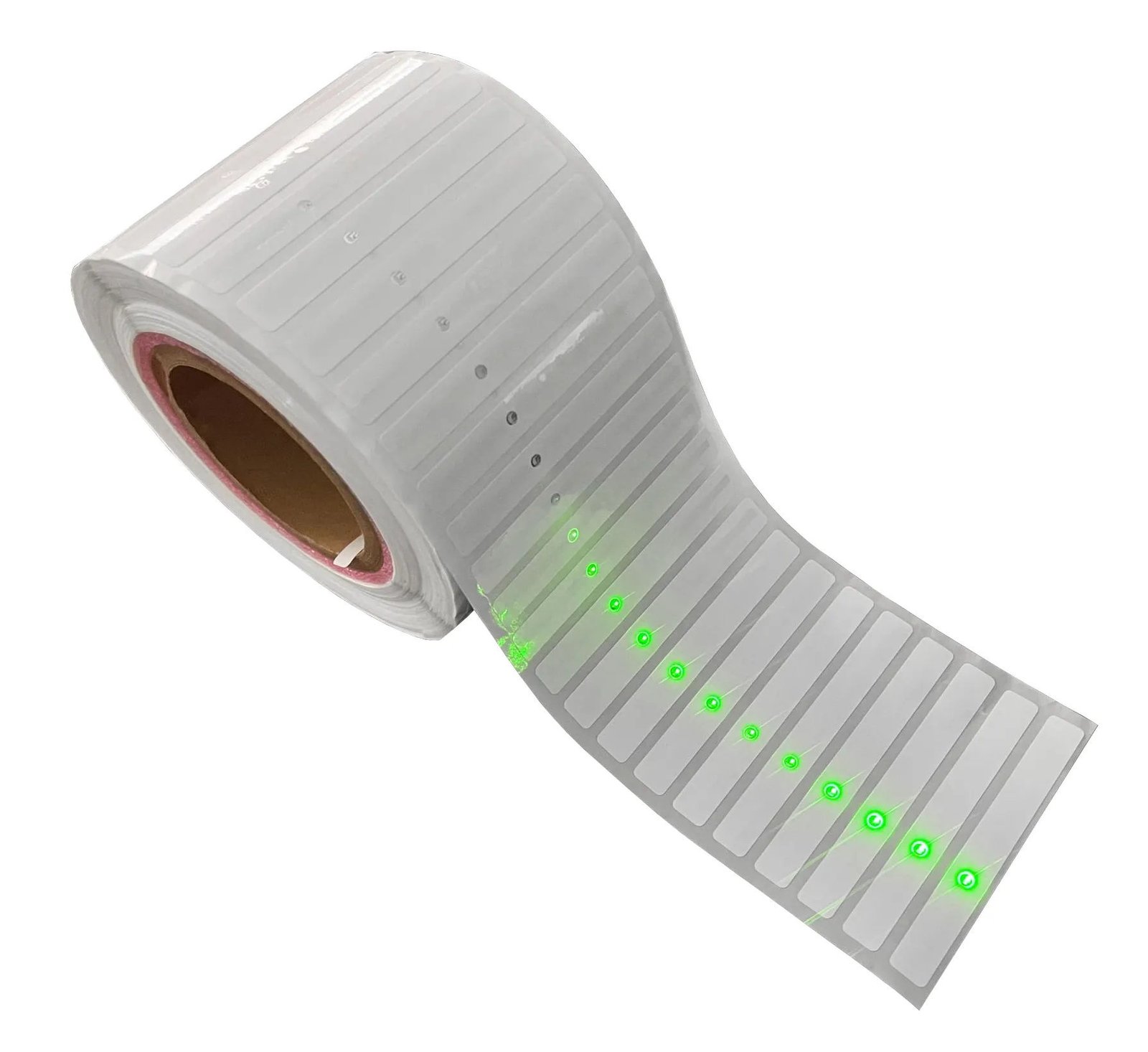

Final Packaging – Supplied in reels, trays, or bulk packaging for industrial use.

Specifications

| Parameter | Value |

|---|---|

| Material | PPS / Industrial Resin |

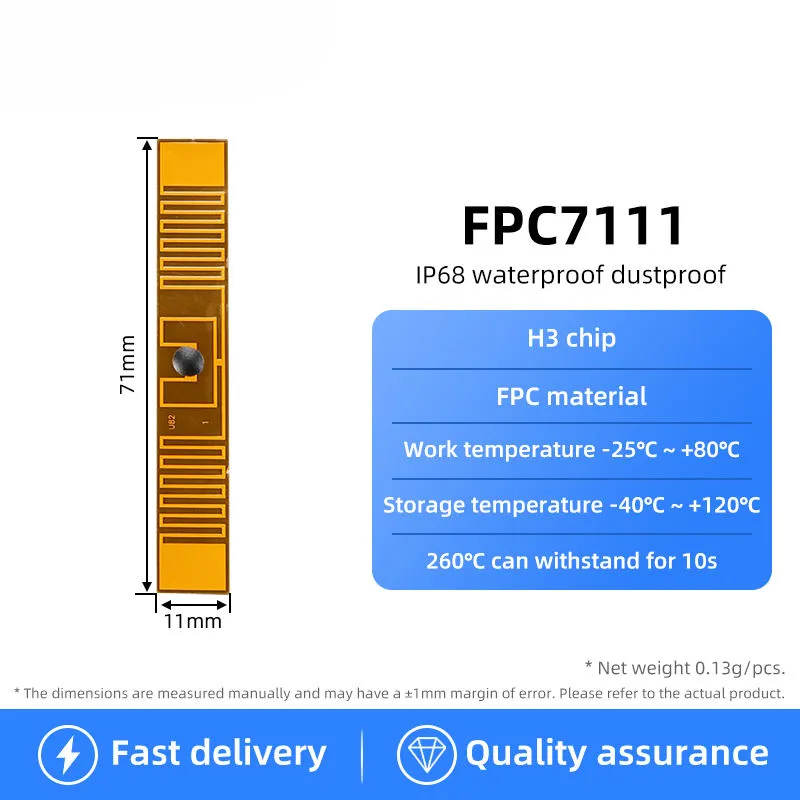

| Frequency | 13.56 MHz (HF) |

| Standards | ISO15693 / ISO14443 |

| Chip Options | NXP ICODE, MIFARE, NTAG series |

| Memory | 128 bytes – 2 KB (depending on chip) |

| Size | 30mm diameter |

| Read Range | 1 – 5 cm (HF) |

| Temperature Resistance | -25°C to +120°C |

| Waterproof Rating | IP68 |

| Mounting Options | Embedding, adhesive, screw fixation |

| Applications | Industry 4.0, automation, logistics, MES, robotics |

| Durability | Resistant to oil, dust, chemicals, and shock |

FAQ

Q1: What is an RFID code carrier in Industry 4.0?

A1: It is a rugged RFID tag embedded in tools, pallets, or components to act as a unique digital identifier in industrial automation systems.

Q2: Can these tags integrate with MES and ERP software?

A2: Yes, they are designed for seamless integration with MES, ERP, and IoT platforms.

Q3: How durable are these RFID tags?

A3: Built with PPS housing, they withstand oil, dust, heat, and mechanical stress, ensuring reliable performance in harsh environments.

Q4: Are these tags reusable?

A4: Yes, they are designed for multiple cycles in industrial production and logistics.

Q5: What industries benefit most from Industry 4.0 RFID tags?

A5: Automotive, electronics, logistics, chemical, smart factories, and robotics industries.