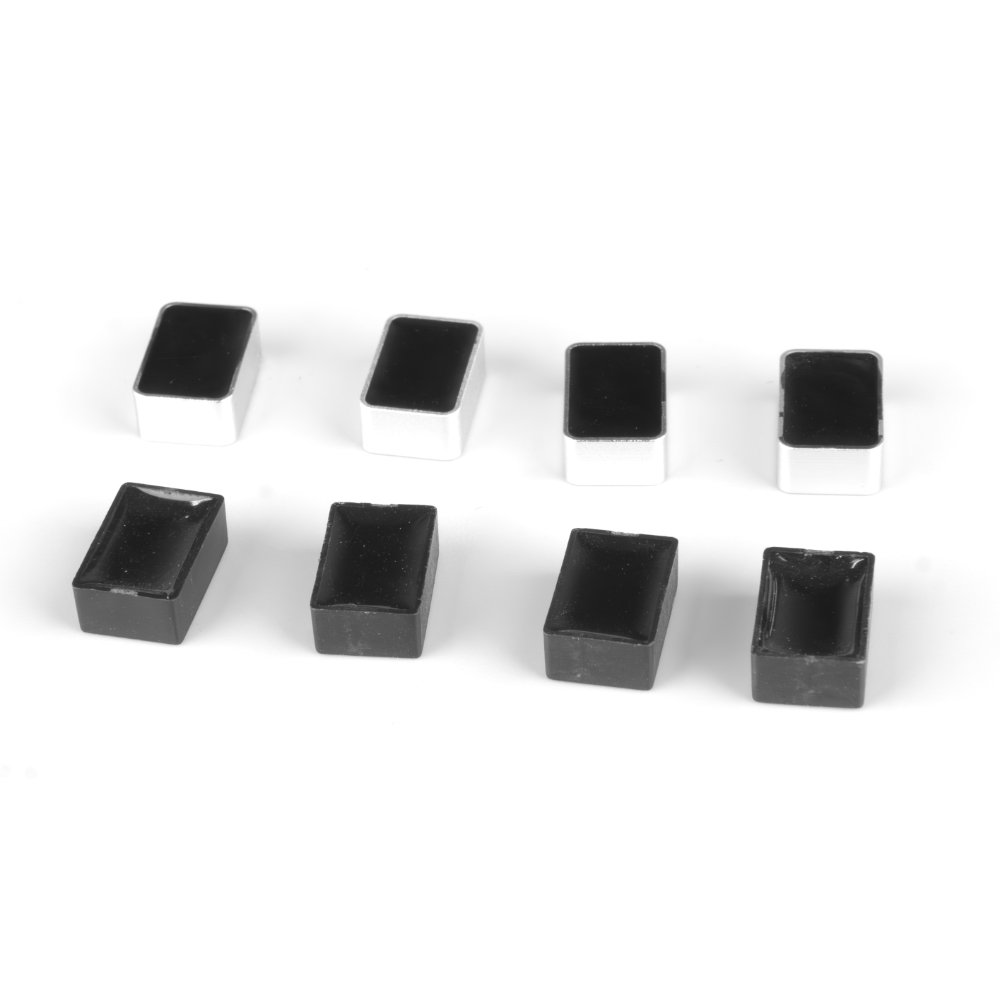

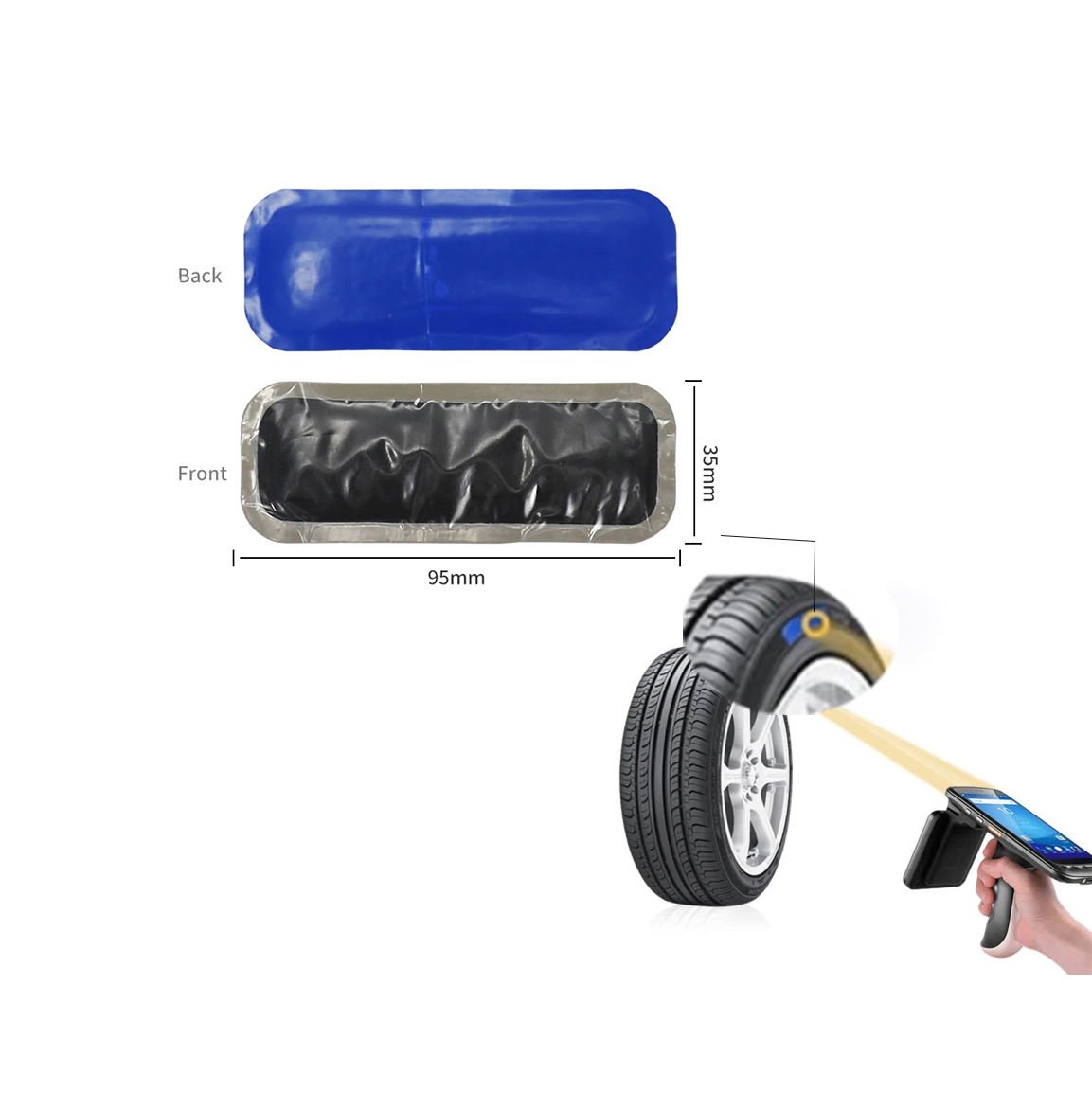

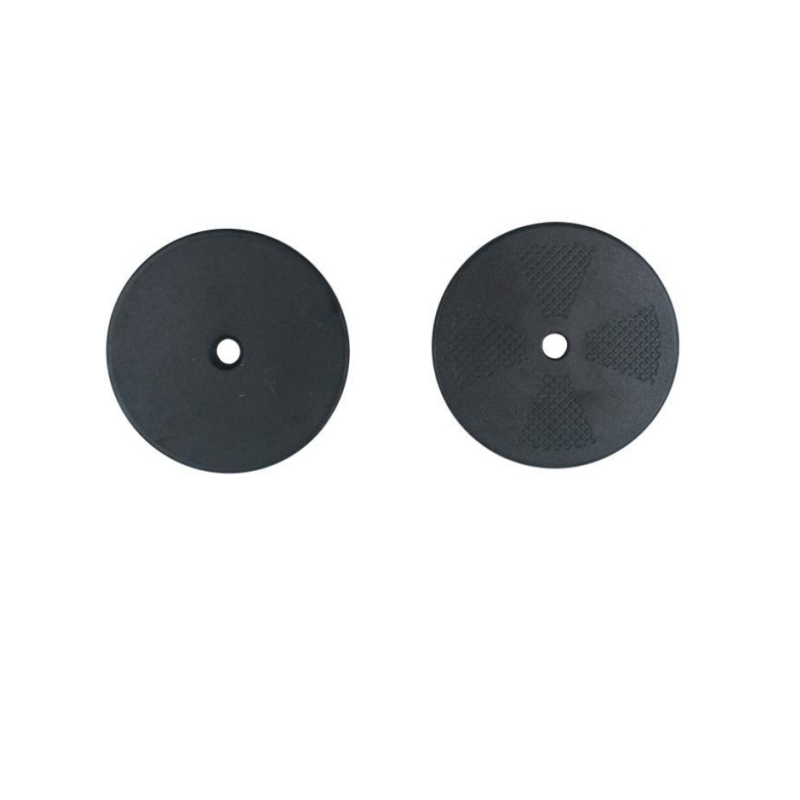

RFID UHF Carrier Tag – Unlimited Read & Write Fujitsu ISO15693 Industrial RFID Tag for Small Pallets, Logistics & Smart Manufacturing

Product Overview

The RFID UHF Carrier Tag is a rugged, compact, and high-performance RFID solution designed for industrial asset tracking, pallet identification, and automated production lines. Engineered with Fujitsu ISO15693-compatible chips, these tags offer unlimited read and write cycles, making them a cost-effective and long-term solution for businesses requiring continuous identification, monitoring, and automation.

Built to withstand harsh industrial environments, the tags feature shock-resistant, waterproof, and temperature-tolerant encapsulation, allowing reliable performance in factories, warehouses, automotive assembly plants, and chemical industries.

Operating at UHF frequency (860–960 MHz), these tags support long read ranges, high-speed identification, and anti-collision technology, ensuring seamless integration into logistics systems, MES (Manufacturing Execution Systems), and Industry 4.0 platforms.

Key Features

-

Unlimited Read & Write Cycles – Designed for continuous, long-term industrial use.

-

UHF RFID Technology – Provides long read range (up to 10 meters).

-

Compact Industrial Design – Suitable for pallets, carriers, and small assets.

-

Durability – Resistant to water, oil, dust, and mechanical stress.

-

ISO15693 Standard Compliance – Ensures global compatibility.

-

High-Speed Identification – Anti-collision ensures multiple tag reads simultaneously.

-

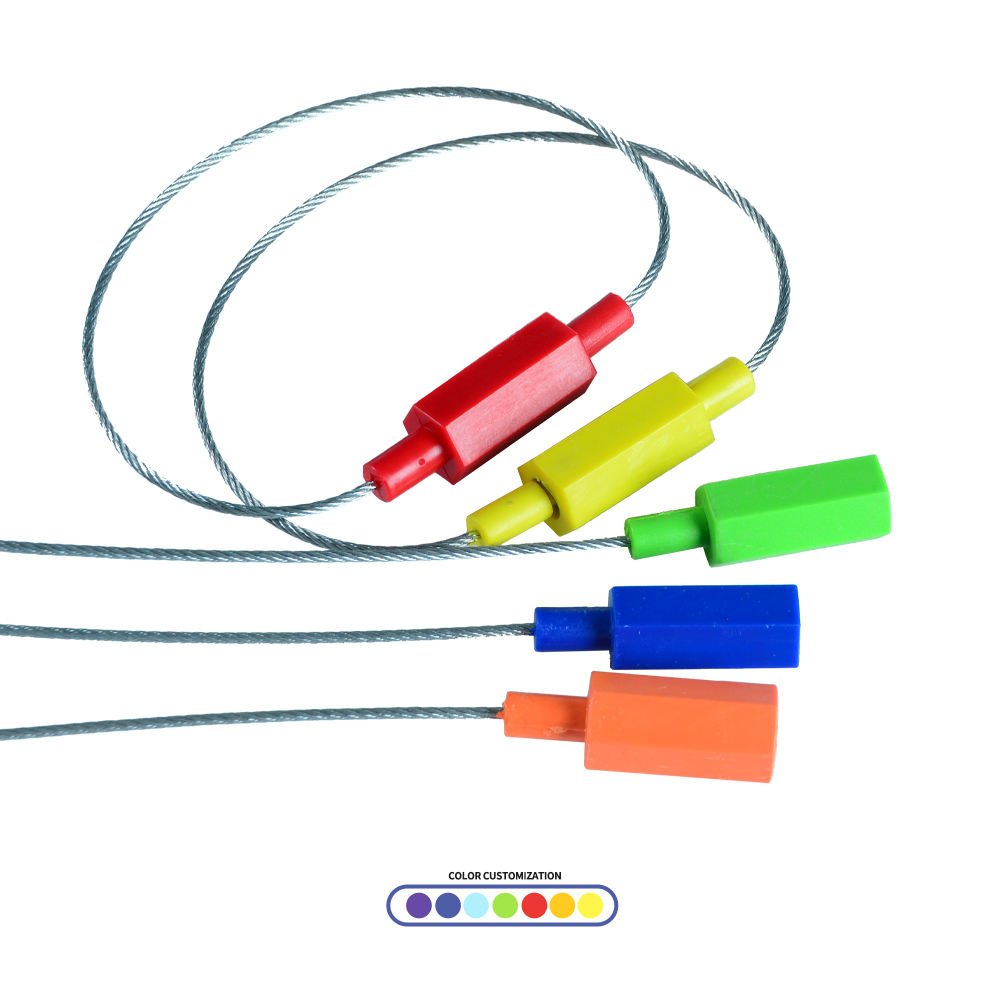

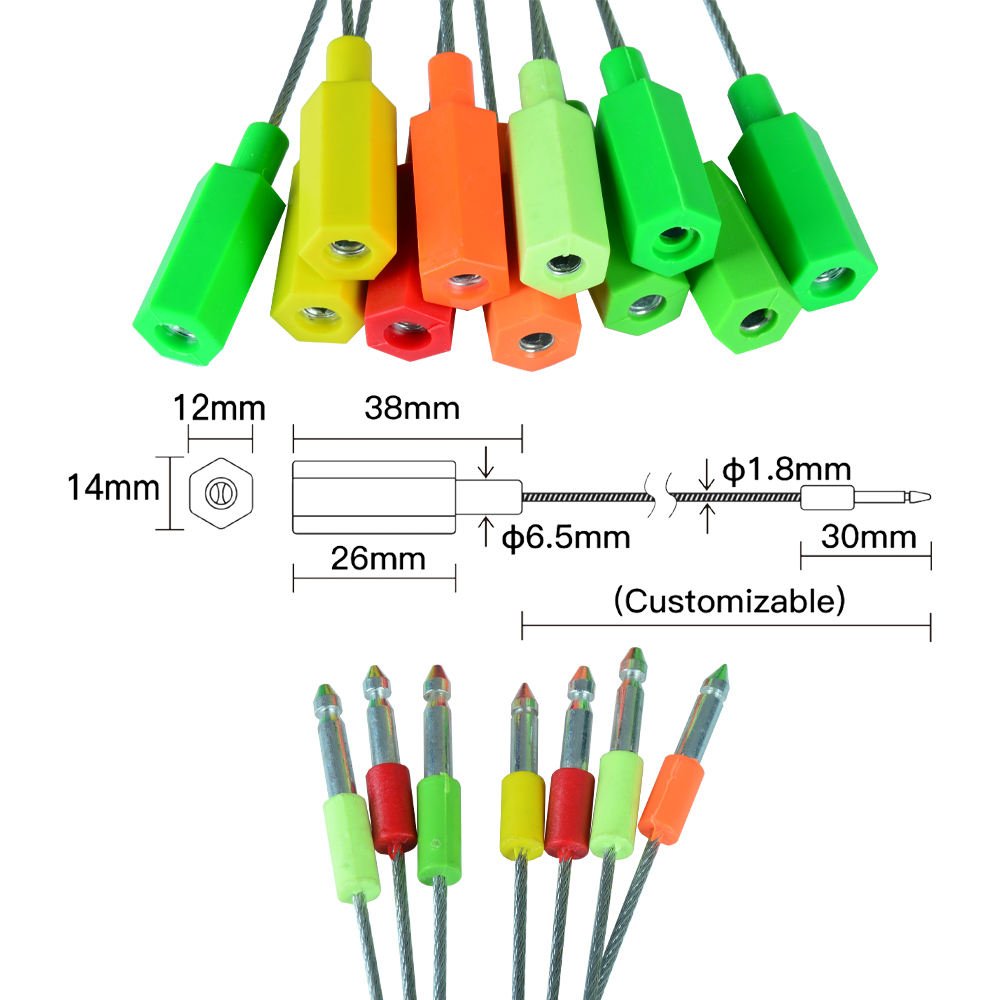

Flexible Mounting Options – Adhesive, screw, or embedded installation.

-

Rewritable & Reusable – Sustainable for long-term tracking applications.

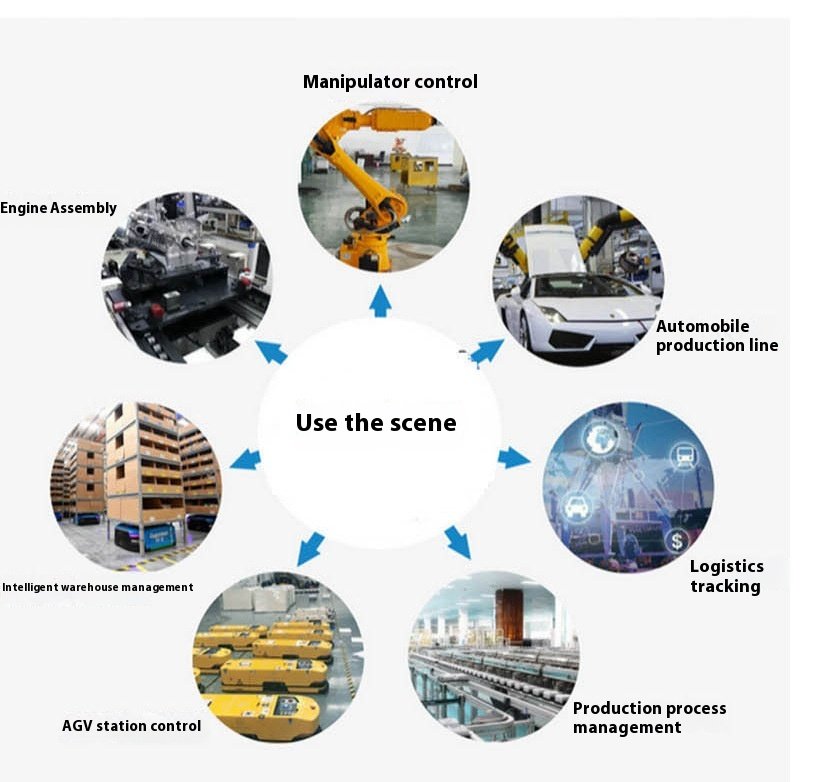

Application Scenarios

1. Smart Manufacturing & Production Line Automation

RFID carrier tags are mounted on work-in-progress carriers and pallets to enable automatic tracking of parts, assemblies, and production workflows.

-

Links directly with MES for real-time production monitoring.

-

Eliminates manual barcode scanning.

-

Supports error-proofing (Poka-Yoke) by ensuring correct parts reach correct stations.

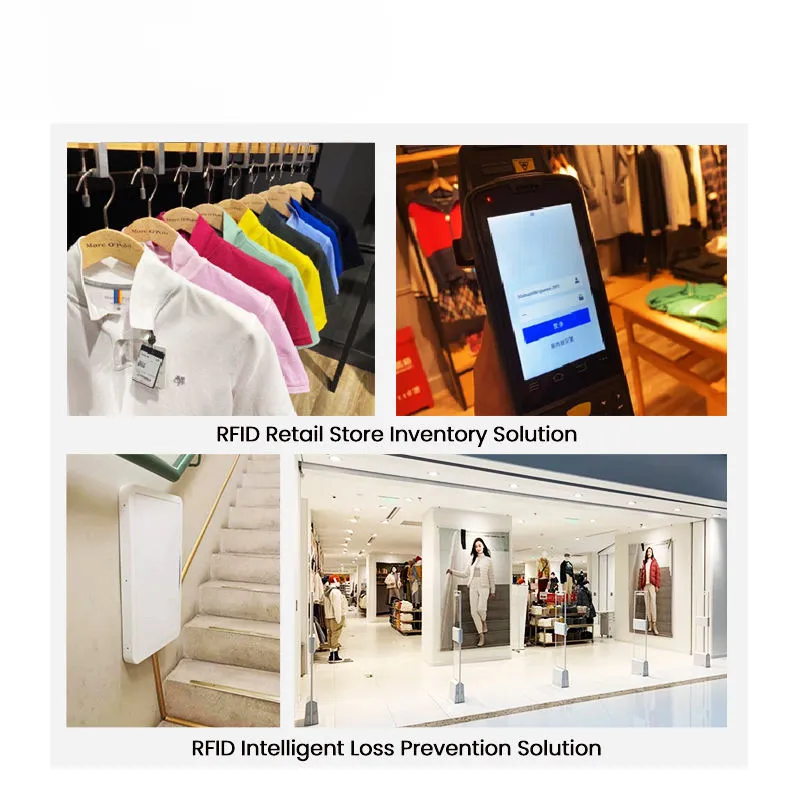

2. Warehouse & Logistics Management

RFID UHF carrier tags allow pallet-level and container-level tracking, giving companies real-time visibility into goods flow across warehouses and supply chains.

-

Automates inventory counts and reduces human error.

-

Integrates with Warehouse Management Systems (WMS).

-

Ensures traceability from factory to distribution center.

3. Automotive & Electronics Industry

Automotive factories use RFID carrier tags in paint shops, welding lines, and assembly stations to maintain traceability and quality control.

-

Withstands high heat and industrial stress.

-

Ensures parts authenticity and compliance.

-

Supports lean manufacturing and JIT (just-in-time) logistics.

4. Chemical & Harsh Environments

Thanks to its durable PPS housing, the RFID carrier tag withstands oil, solvents, acid, and alkali, making it suitable for chemical plants, refineries, and hazardous material handling.

-

Enhances safety compliance tracking.

-

Provides long-term identification in corrosive settings.

-

Works reliably even after repeated wash cycles.

5. Reusable Packaging & Asset Tracking

Companies using reusable pallets, crates, and industrial packaging can embed RFID UHF tags to ensure tracking through multiple logistics cycles.

-

Reduces losses of reusable assets.

-

Enables eco-friendly, sustainable supply chains.

-

Supports reverse logistics and returnable container tracking.

Product Advantages

-

Unlimited Read/Write – True sustainability for industrial use.

-

Global Standards – ISO15693 compliance ensures interoperability.

-

Durable Housing – Withstands extreme conditions and repeated cycles.

-

Cost-Effective – Reduces long-term TCO by enabling reusability.

-

Automation Ready – Seamless integration with ERP, MES, and IoT.

-

Compact & Versatile – Suitable for a wide range of industrial and logistics assets.

Production Process

-

Material Selection – PPS or industrial-grade resin prepared.

-

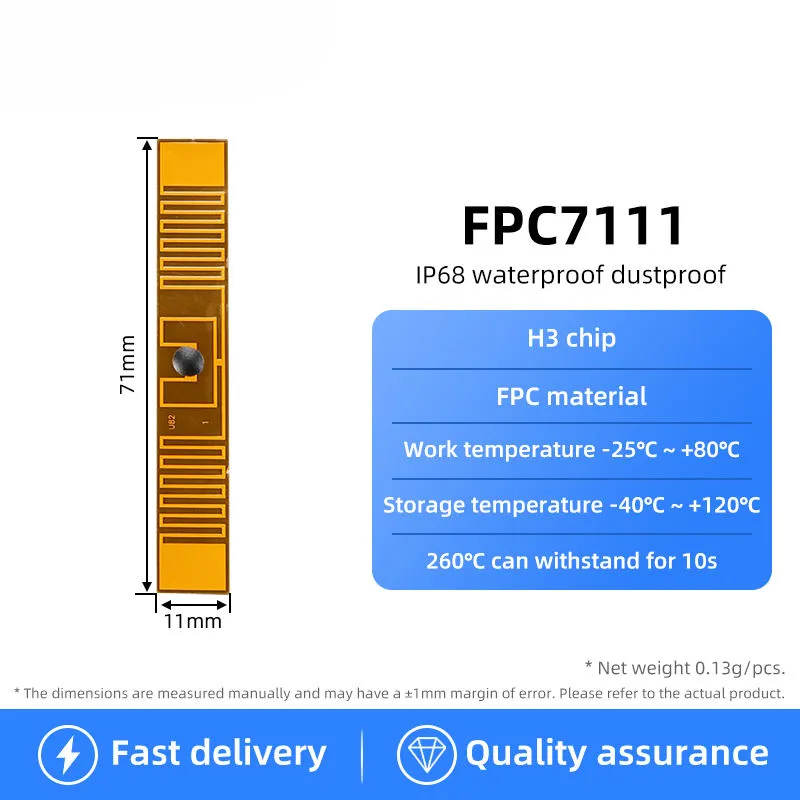

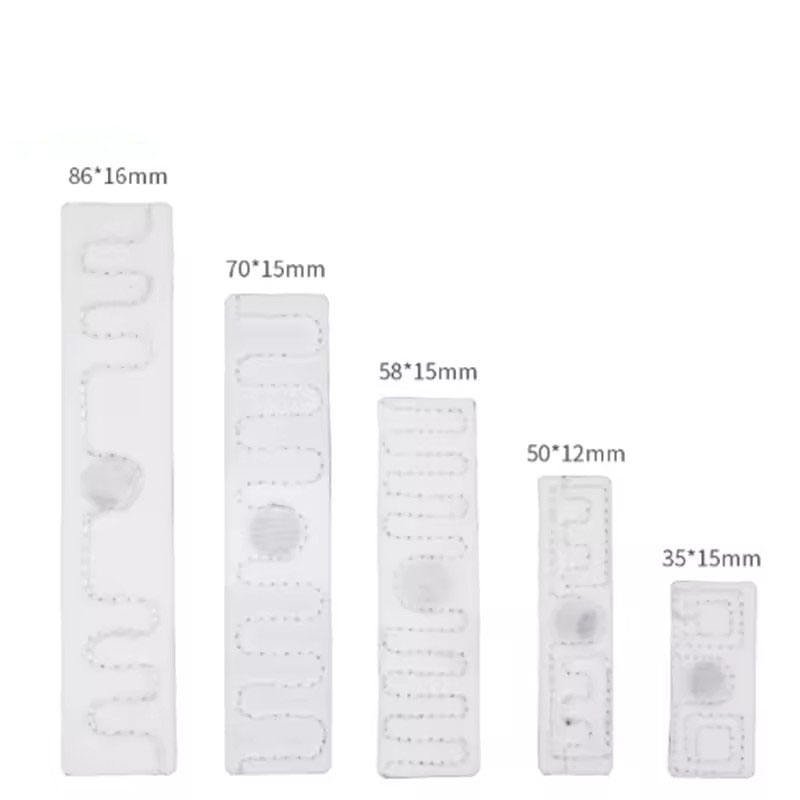

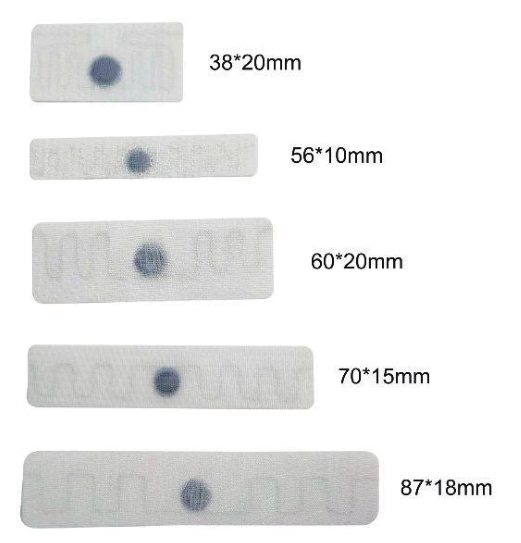

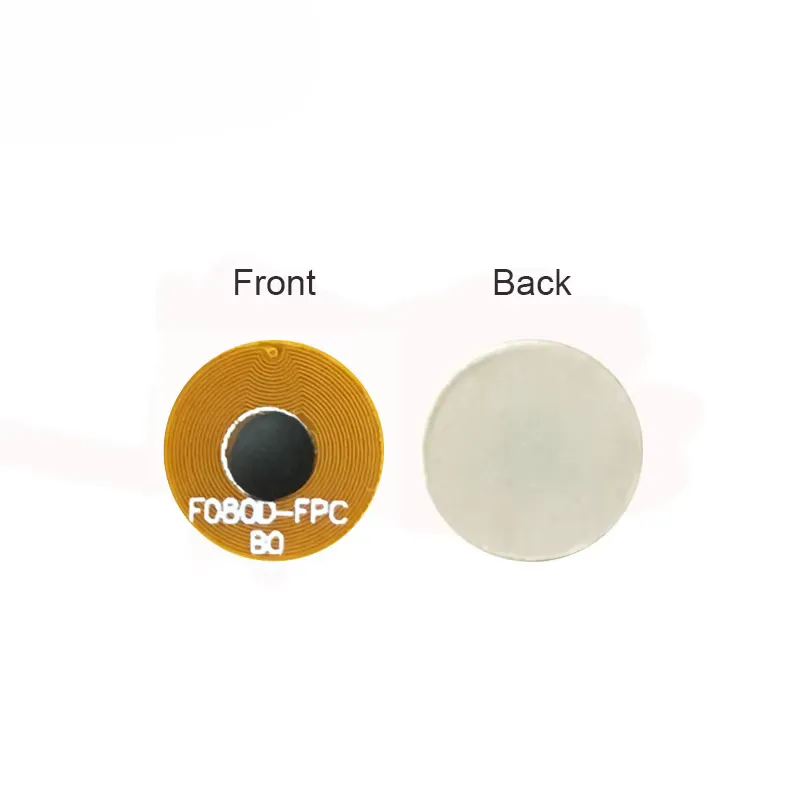

Chip Integration – Fujitsu ISO15693 chip embedded with antenna.

-

Encapsulation – Molded for shock, dust, and chemical resistance.

-

Signal Optimization – UHF tuning for long-range and multi-tag reading.

-

Encoding – EPC memory and user data programmed as required.

-

Testing – Stress tests for temperature, shock, and waterproofing.

-

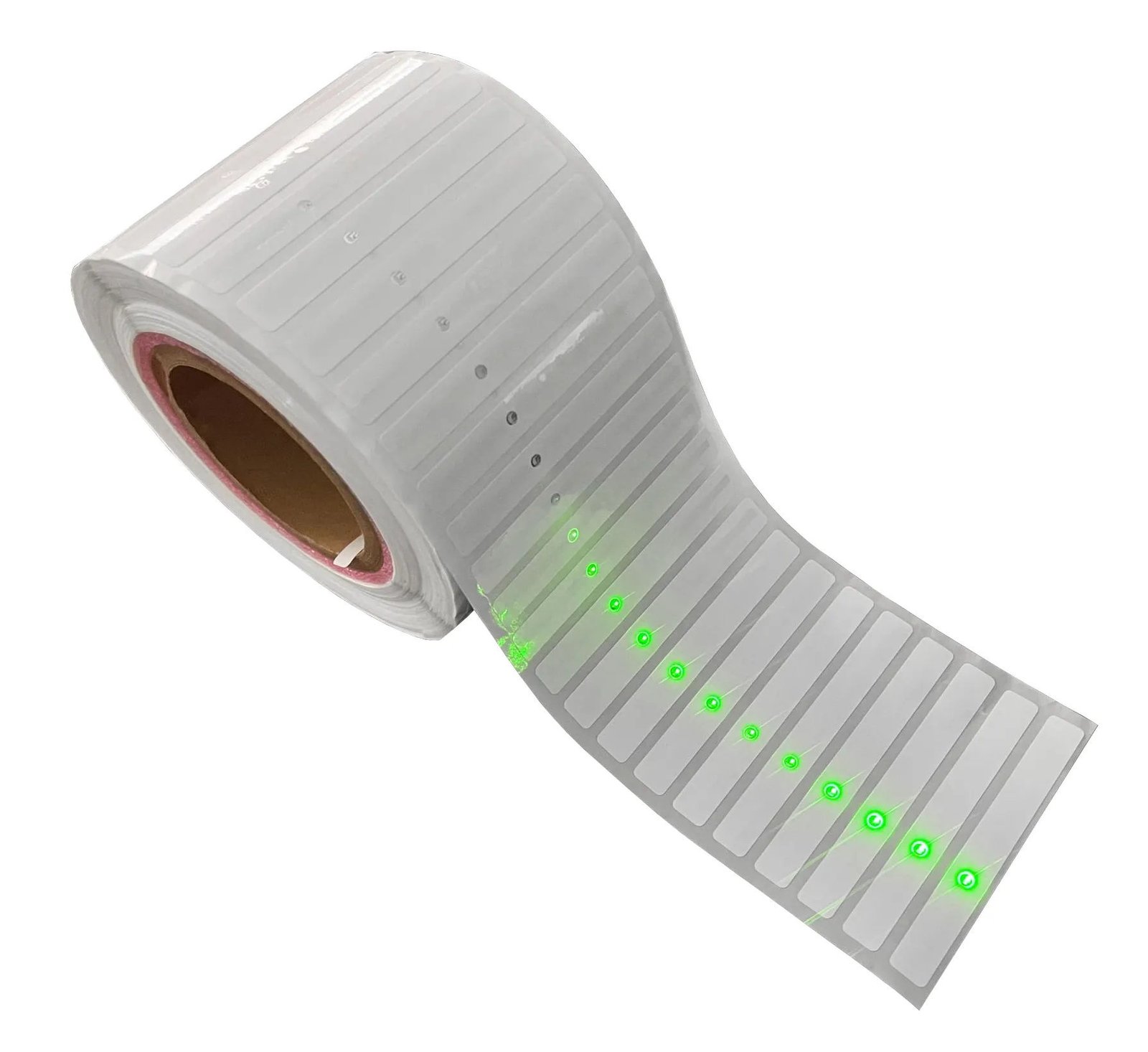

Packaging – Supplied in reels, trays, or custom packaging.

Specifications

| Parameter | Value |

|---|---|

| Material | PPS / Industrial Resin |

| Frequency | 860–960 MHz (UHF) |

| Standards | ISO15693 / EPC Gen2 |

| Chip Options | Fujitsu Industrial Chipset |

| Memory | 512 bits – 2 KB |

| Read Range | Up to 10 meters |

| Write/Read Cycles | Unlimited |

| Size | Compact (for pallets and carriers) |

| Temperature Resistance | -40°C to +200°C |

| Waterproof Rating | IP68 |

| Mounting Options | Adhesive, screw, or embedded |

| Applications | Manufacturing, logistics, automotive, chemical, reusable packaging |

| Durability | Oil, dust, solvent, and impact resistant |

FAQ

Q1: What makes this RFID tag different from regular UHF tags?

A1: It supports unlimited read/write cycles and is designed specifically for industrial use with extreme durability.

Q2: Can this tag be reused on different pallets?

A2: Yes, it is fully rewritable and can be reused across multiple supply chain cycles.

Q3: Is it compatible with global RFID readers?

A3: Yes, it complies with ISO15693 and EPC Gen2 standards.

Q4: Can it survive chemical exposure?

A4: Yes, PPS housing ensures resistance to solvents, oils, acid, and alkali.

Q5: What industries benefit most from this tag?

A5: Manufacturing, automotive, logistics, chemical plants, and reusable packaging supply chains.