UHF Mini RFID Tire Patch Tag – Long Range Passive Tire Management Tag (860–960MHz)

1. Introduction: Smart RFID for Tire Lifecycle Management

The automotive industry increasingly requires accurate tire identification, lifecycle monitoring, and anti-counterfeit protection. The Sunlanrfid UHF Mini RFID Tire Patch Tag is designed specifically for tire manufacturers, fleet operators, and distributors, offering long-range passive RFID performance at 860–960MHz.

Its compact patch design allows easy embedding or attachment inside tire structures, while its rugged construction ensures resistance to heat, pressure, and outdoor conditions. This makes it the ideal solution for tire management, warranty tracking, and vehicle safety compliance.

2. What is a Mini RFID Tire Patch Tag?

A mini RFID tire patch tag is a passive UHF RFID transponder developed for integration into tires. It provides:

-

Unique identification for each tire.

-

Bulk and long-range readability for supply chain efficiency.

-

High durability in extreme tire environments.

This ensures accurate lifecycle management from manufacturing to recycling, reducing fraud and improving operational visibility.

3. Key Features

-

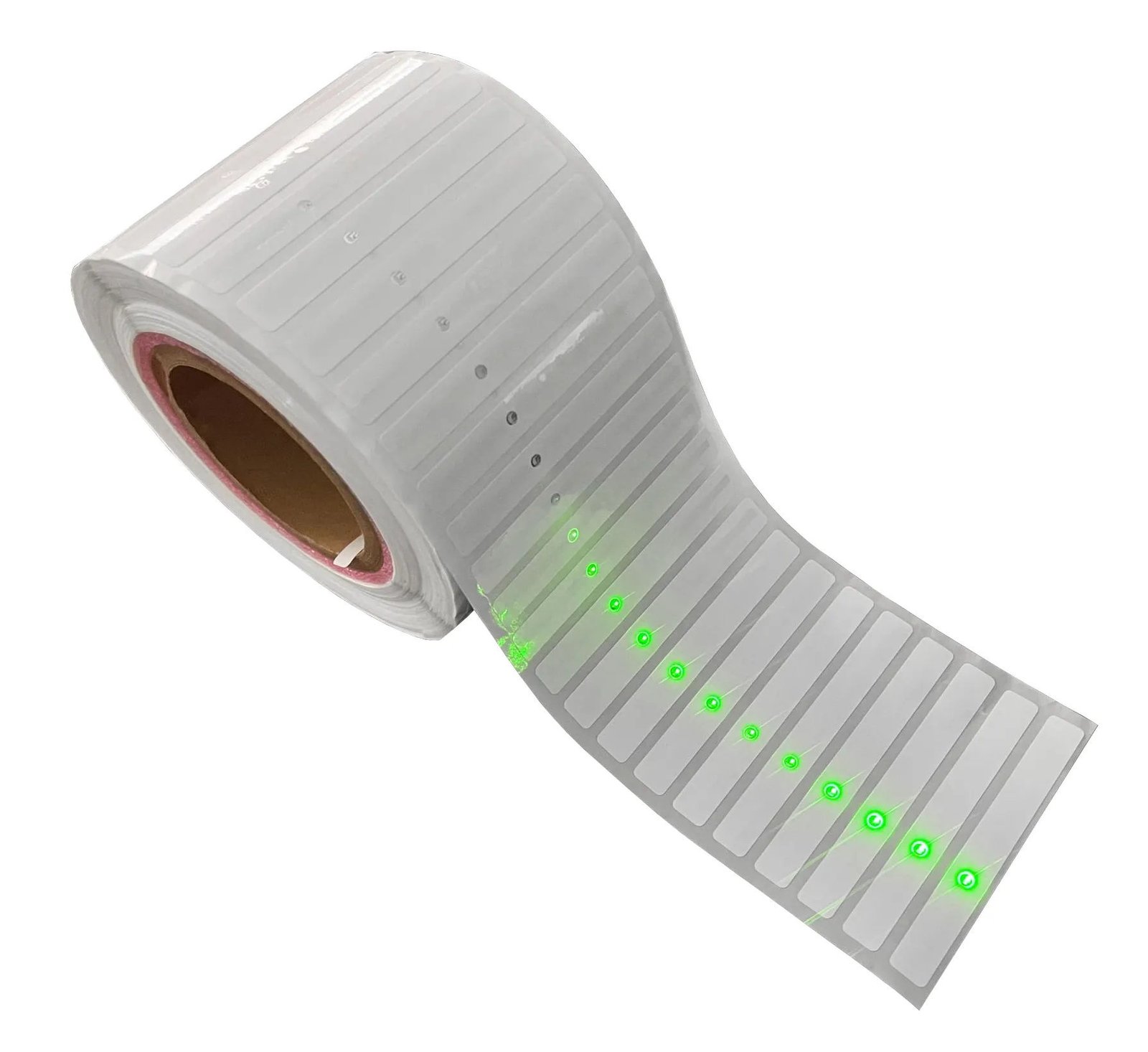

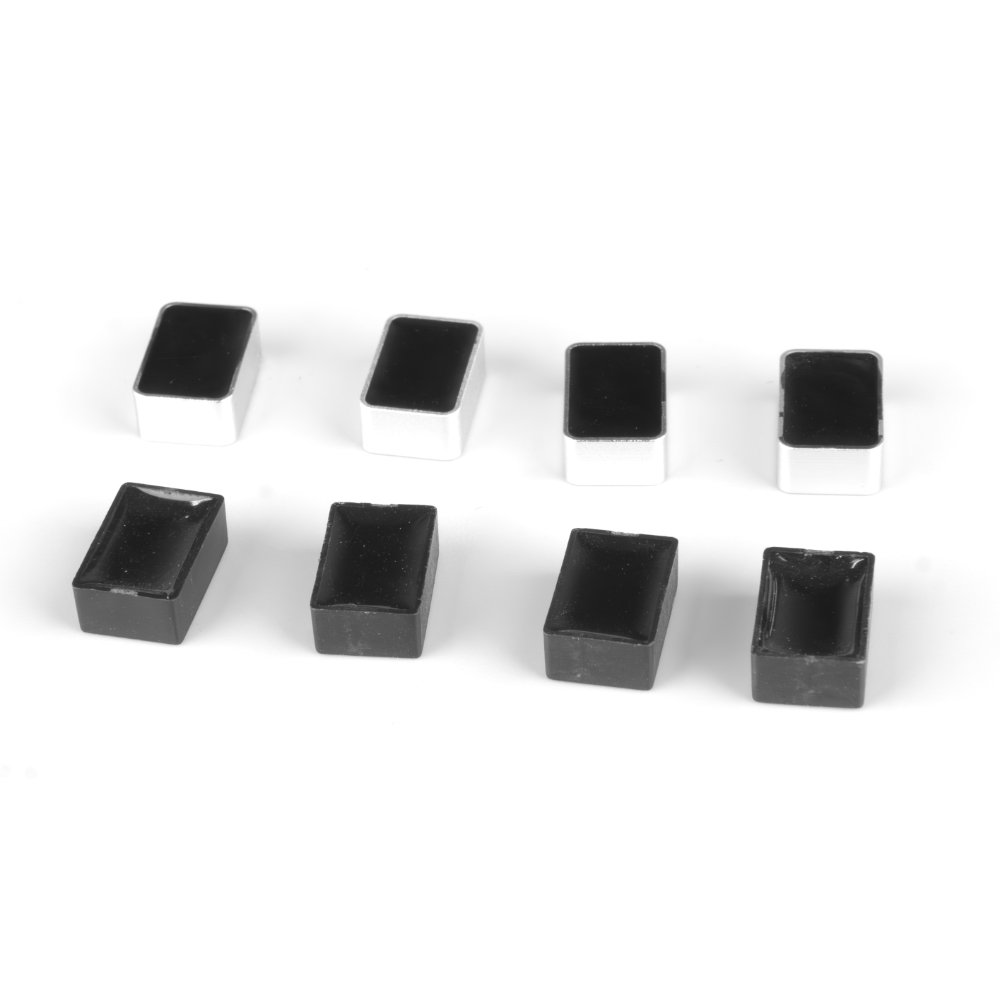

Mini Compact Design

-

Small footprint for easy integration into tires.

-

Suitable for both passenger and commercial vehicles.

-

-

Long-Range Passive UHF

-

Operates at 860–960MHz.

-

EPC Gen2 / ISO18000-6C compliant.

-

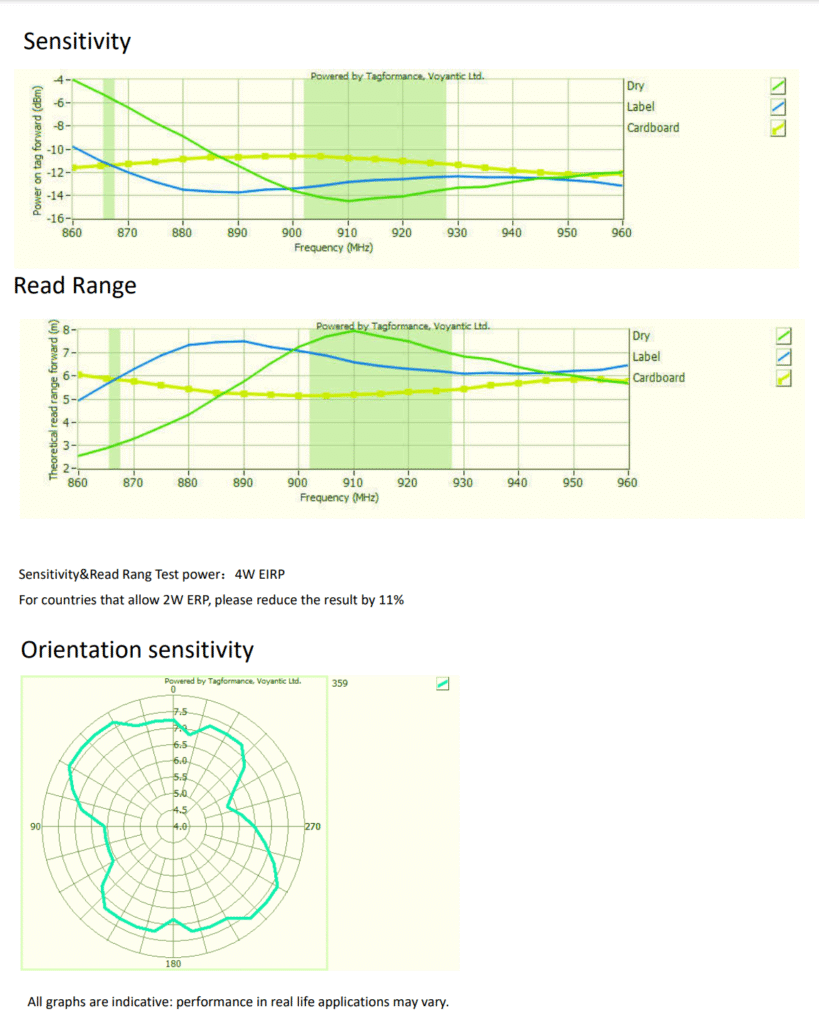

Read range up to 3–6 meters.

-

-

High Durability

-

Resistant to heat, pressure, water, and outdoor conditions.

-

Designed for tire embedding and long lifecycle usage.

-

-

Cost-Effective & Passive

-

No battery required.

-

Scalable for mass tire production and management.

-

-

Customizable Options

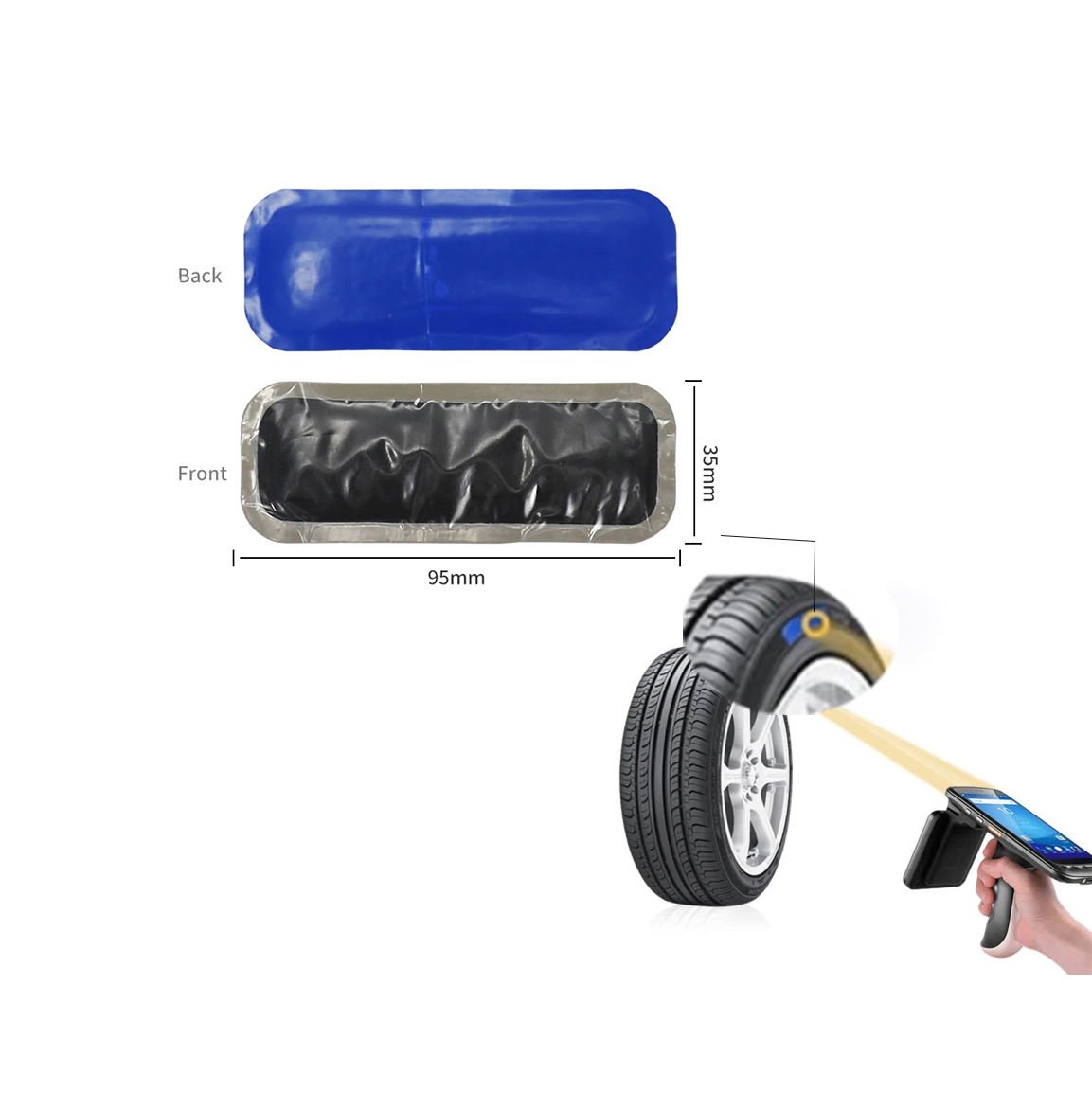

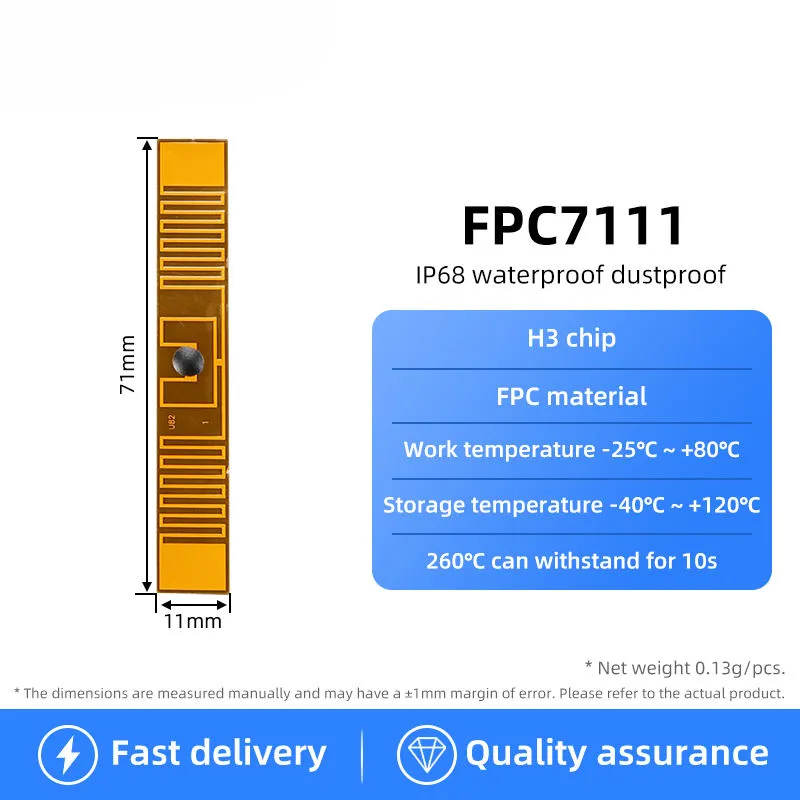

4. Technical Specifications

| Parameter | Details |

|---|---|

| Frequency Range | 860–960MHz (UHF RFID) |

| Protocols | EPCglobal Class 1 Gen2 / ISO18000-6C |

| Read Range | 3–6 meters |

| Chip Options | Impinj Monza, NXP UCODE, Alien Higgs |

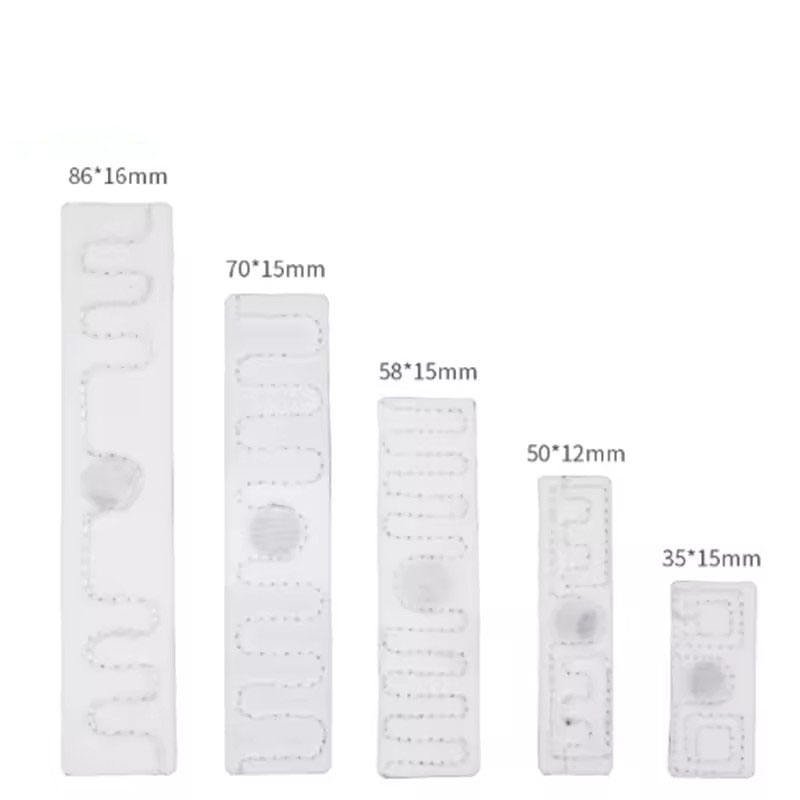

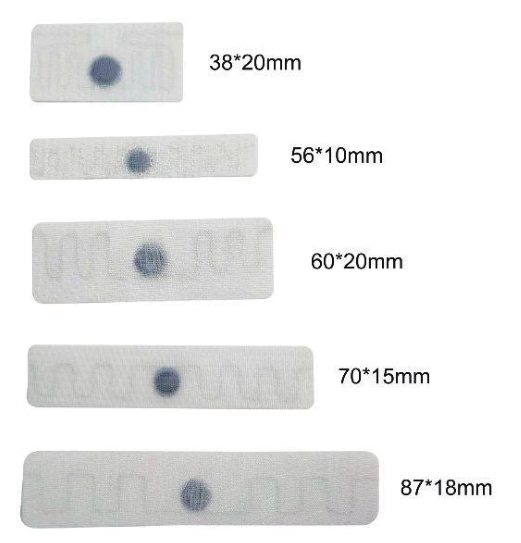

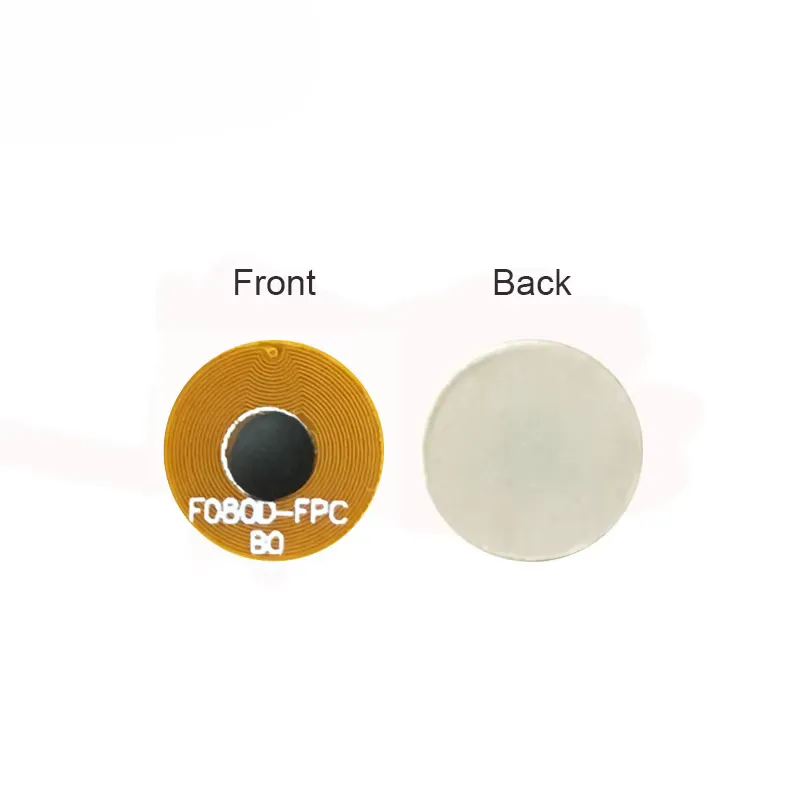

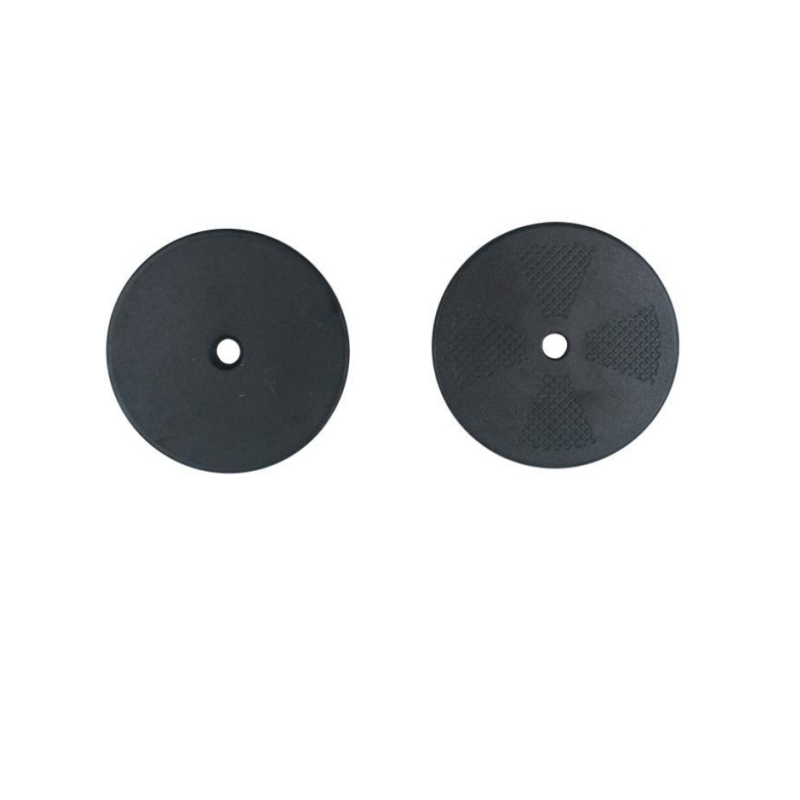

| Form Factor | Mini patch design |

| Material | High-temperature resistant encapsulation |

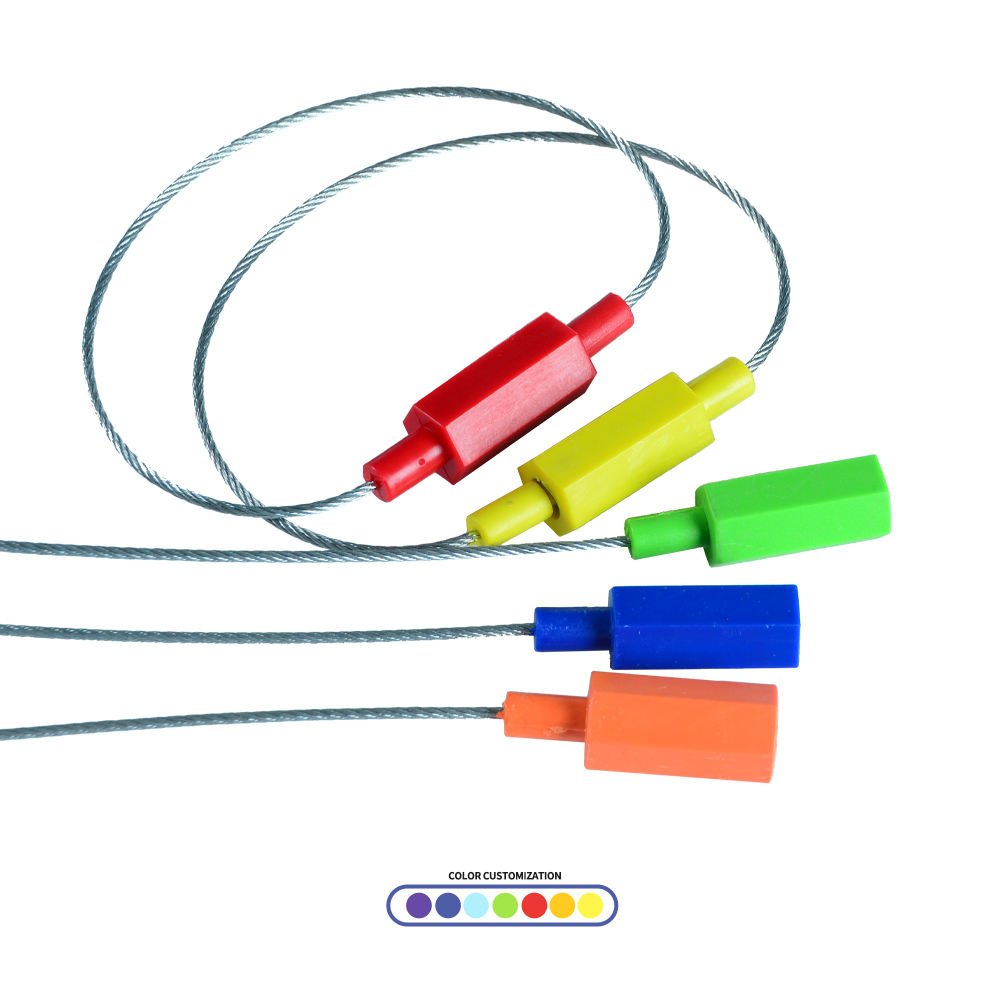

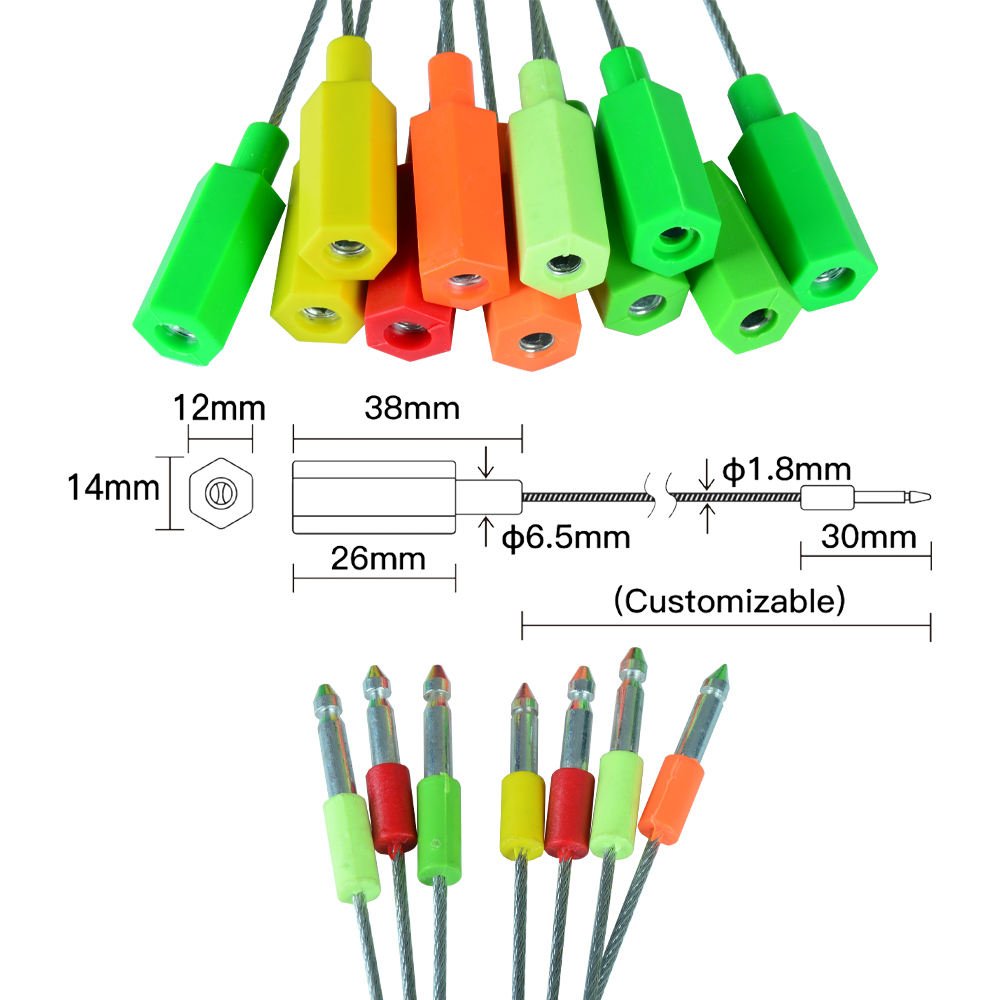

| Attachment Methods | Embedded in tire or affixed with patch adhesive |

| Operating Temp | -40°C to +250°C |

| Applications | Tire management, vehicle tracking, fleet operations, supply chain logistics |

5. Advantages Over Standard RFID Tags

-

Compact mini design – easy to embed without affecting tire structure.

-

High durability – withstands heat, friction, and pressure inside tires.

-

Passive & cost-effective – scalable for mass production.

-

Long-range readability – efficient scanning in warehouses and checkpoints.

-

Lifecycle tracking – improves safety, warranty, and compliance.

6. Applications

-

Tire Manufacturers – product authentication and serial tracking.

-

Fleet Management – monitor tire usage, replacement cycles, and safety.

-

Automotive Supply Chain – ensure accurate inventory and logistics.

-

Retail & Distribution – anti-theft and counterfeit prevention.

-

Government & Compliance – digital tire ID for safety inspections.

7. Customization Options

-

Chip model and memory capacity.

-

Branding with logo, barcode, or QR code.

-

Pre-encoding with EPC data.

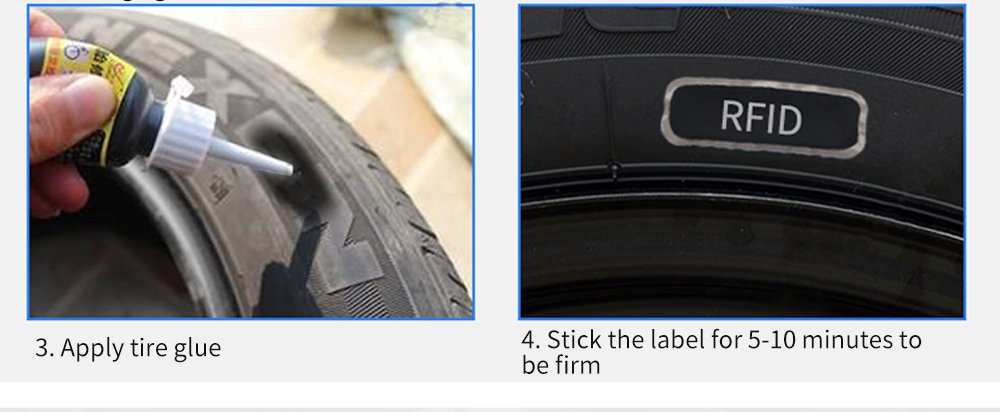

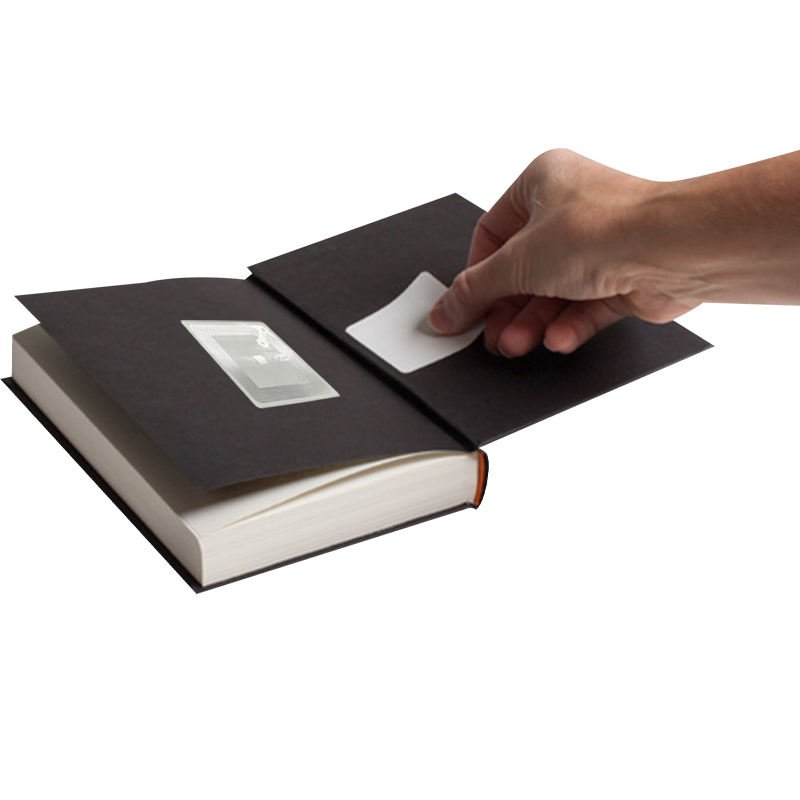

8. Installation & Deployment

-

Embed or patch tag into tire during production or after-market installation.

-

Encode with unique tire ID and data.

-

Use UHF RFID readers for scanning at checkpoints or warehouses.

-

Integrate with ERP or fleet management platforms for lifecycle visibility.

9. Frequently Asked Questions (FAQ)

Q1: Can the mini patch tag survive inside tires?

Yes, it is built for high temperature and pressure environments.

Q2: What is the read range?

3–6 meters depending on reader and conditions.

Q3: Can it be reused?

No, it is designed for permanent tire lifecycle tracking.

Q4: What standards does it support?

EPC Gen2 / ISO18000-6C.

Q5: Who benefits most from these tags?

Tire manufacturers, fleet operators, and automotive distributors.

10. Conclusion

The Sunlanrfid UHF Mini RFID Tire Patch Tag is a durable, compact, and passive RFID solution for tire lifecycle management. With its long-range readability, high durability, and cost-effectiveness, it enables manufacturers, fleets, and retailers to improve efficiency, reduce fraud, and ensure compliance.