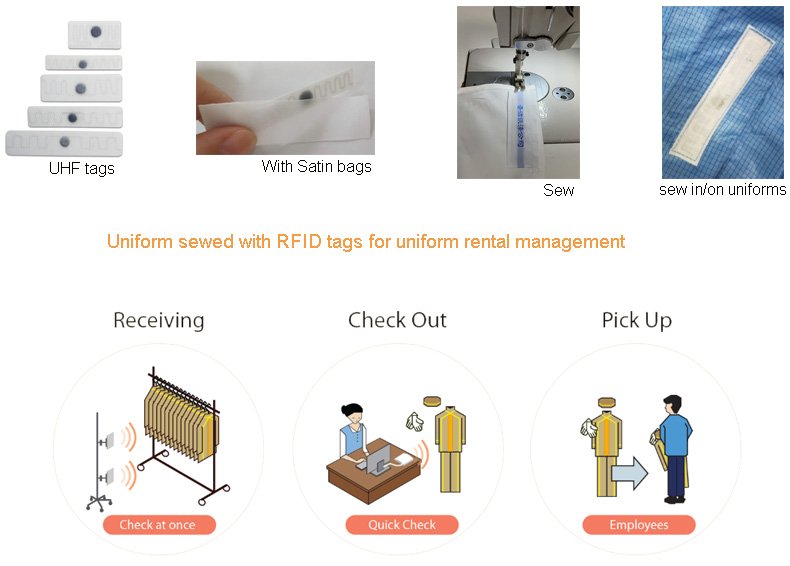

UHF Textile Apparel RFID Laundry Chips – Linen Management Laundry Tag for Hotels

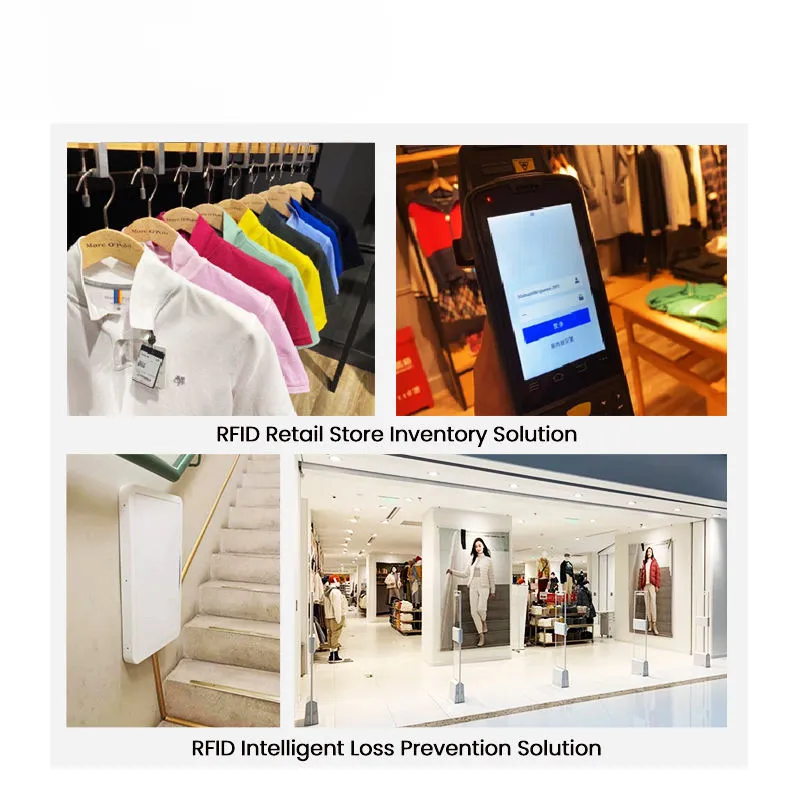

1. Introduction: Smart RFID for Linen & Laundry Management

Hotels, hospitals, and industrial laundries handle thousands of textiles daily, from bed sheets and towels to uniforms and garments. Traditional manual tracking methods are inefficient, error-prone, and costly. The UHF Textile Apparel RFID Laundry Tag provides a durable, washable, and long-range tracking solution, enabling businesses to achieve real-time visibility, efficient linen circulation, and reduced losses.

Designed with UHF RFID technology, these tags can withstand high temperatures, chemicals, and mechanical stress during repeated washing and ironing cycles, making them perfect for hotel and hospital linen management.

2. What is a Textile RFID Laundry Tag?

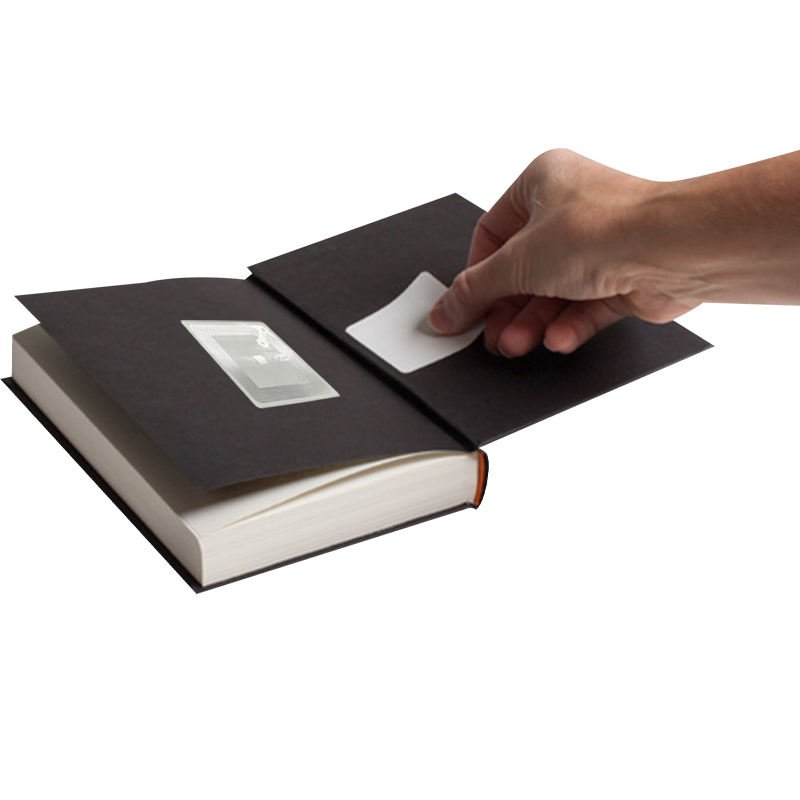

A textile RFID laundry tag is a washable RFID chip embedded in textiles, garments, or linen items. It provides:

-

Unique digital identity for each textile piece.

-

Automated tracking during washing, drying, and distribution.

-

Lifecycle management for monitoring usage and replacement needs.

With UHF RFID long-range capability, hundreds of tagged items can be scanned simultaneously, streamlining inventory and logistics operations.

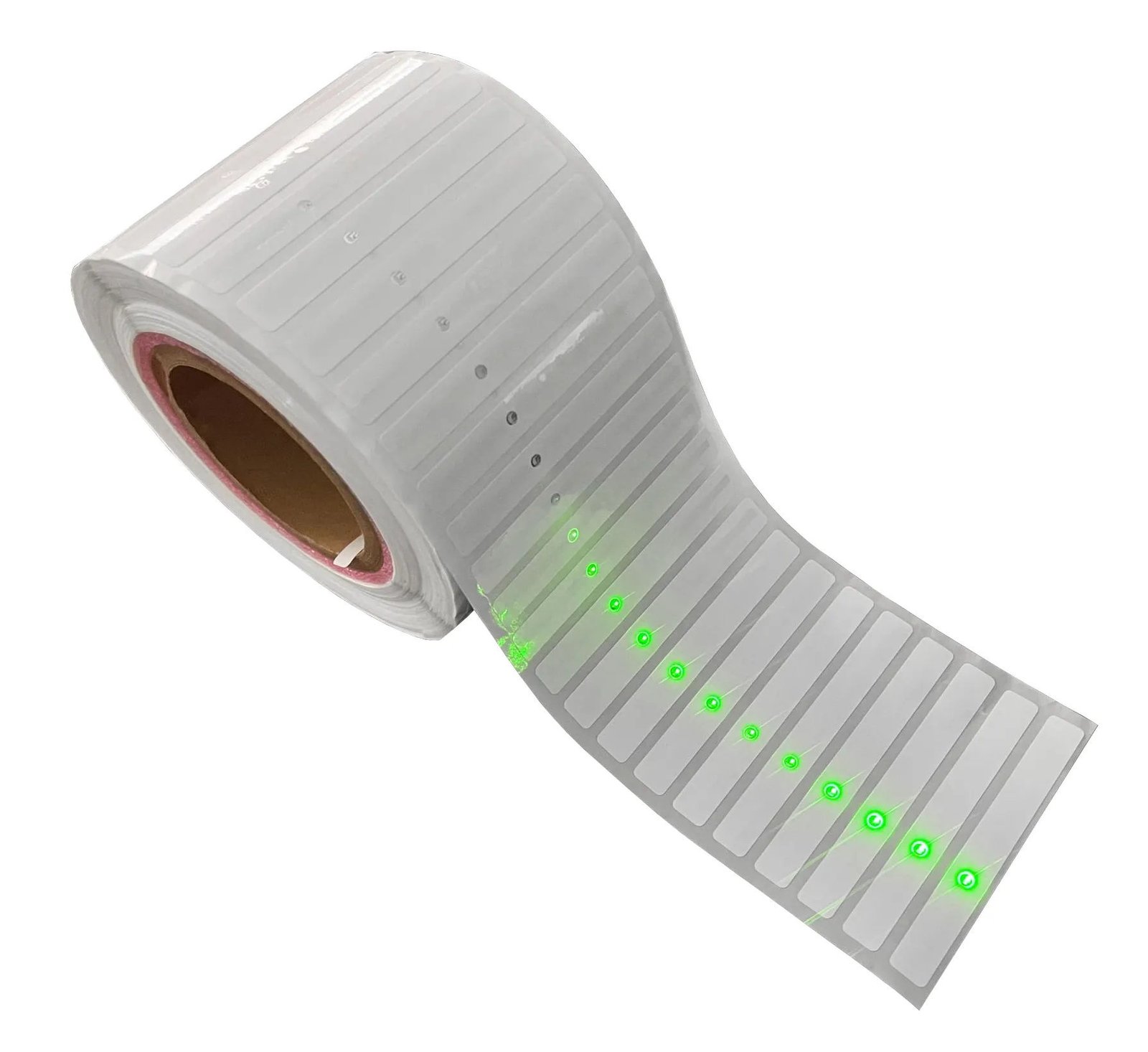

3. Key Features

-

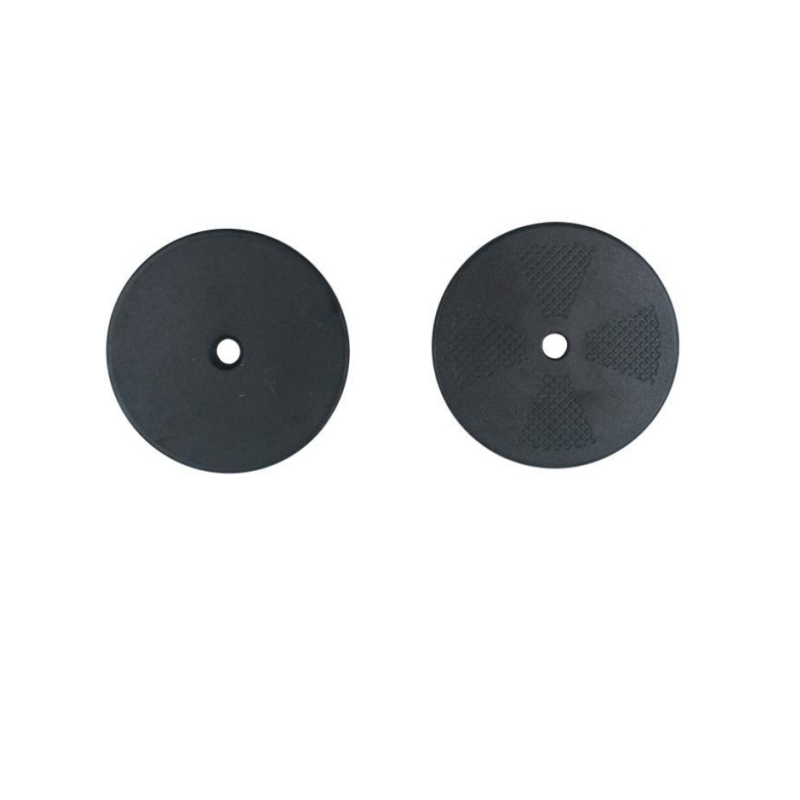

Washable & Heat-Resistant

-

Designed for 200+ wash cycles.

-

Resistant to detergents, bleach, and sterilization processes.

-

-

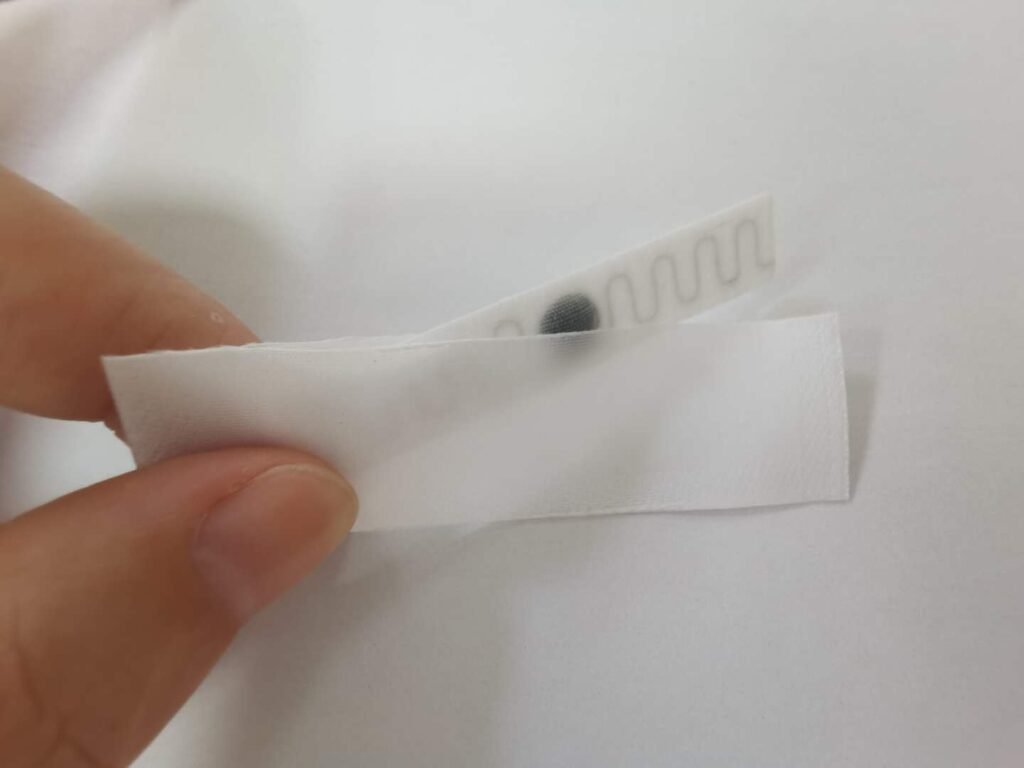

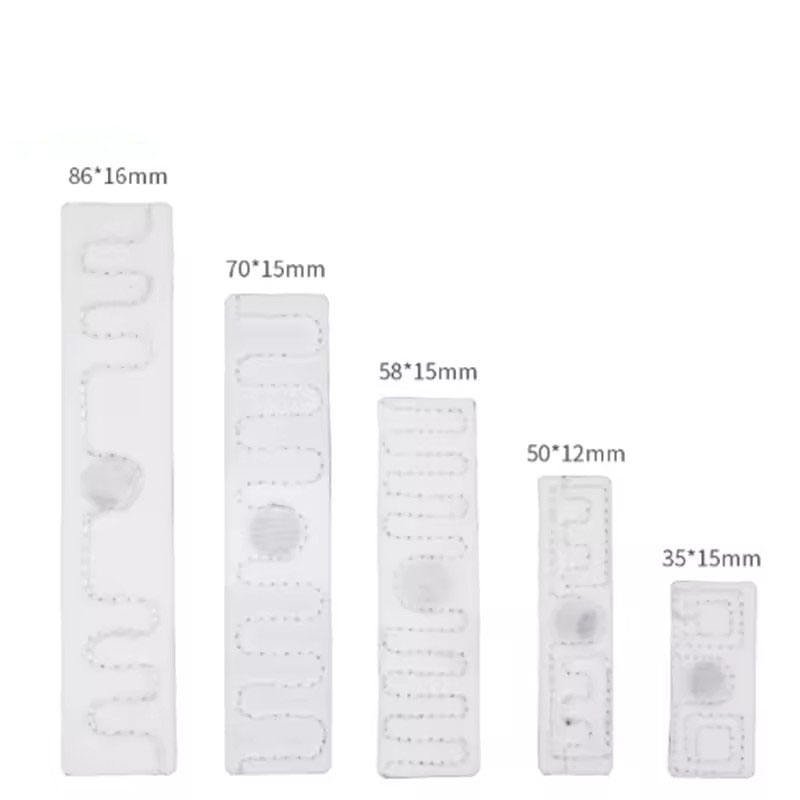

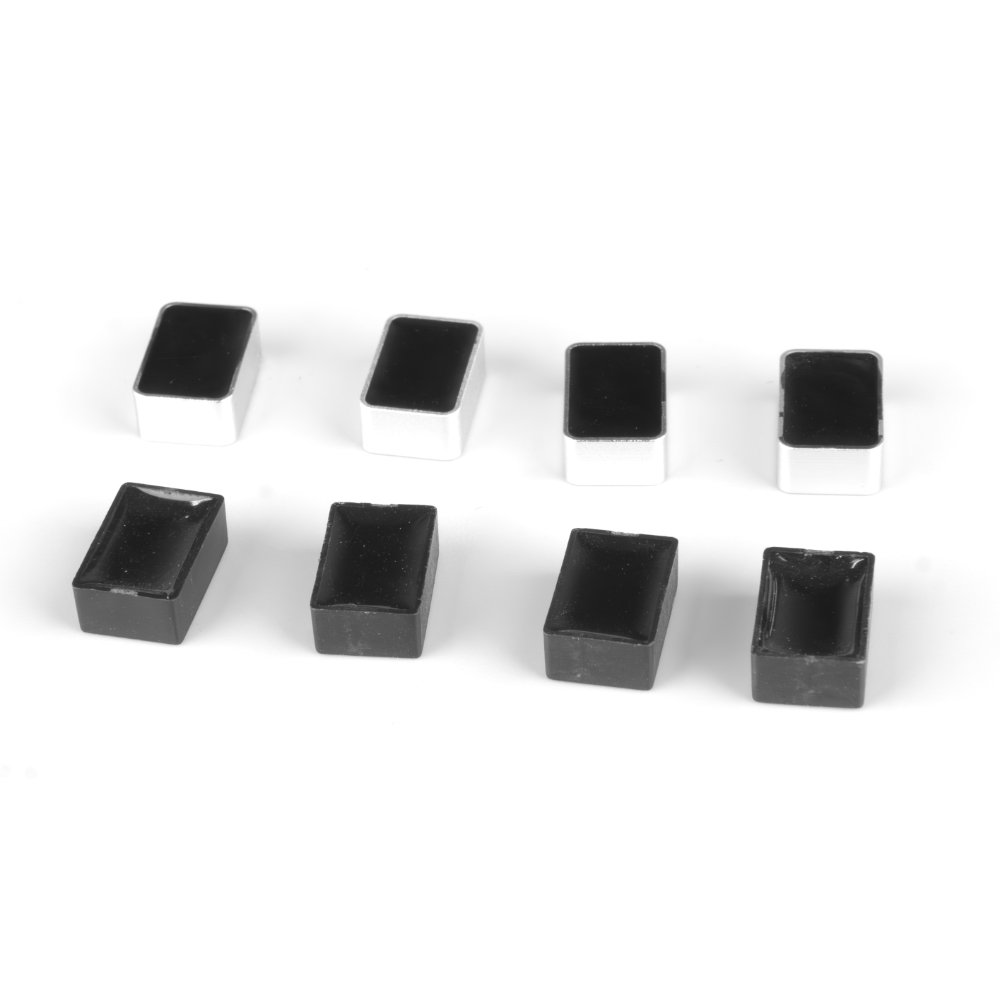

Durable Textile Embedding

-

Soft and flexible, suitable for sewing, heat-sealing, or inserting.

-

Comfortable for apparel and invisible in use.

-

-

UHF Long-Range Performance

-

Read range up to 3–6 meters.

-

Supports EPC Gen2 / ISO18000-6C protocols.

-

-

Lifecycle Management

-

Track textile usage history.

-

Identify aging linens and reduce theft or loss.

-

-

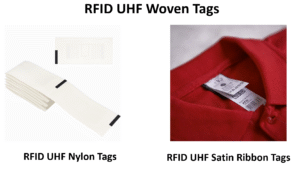

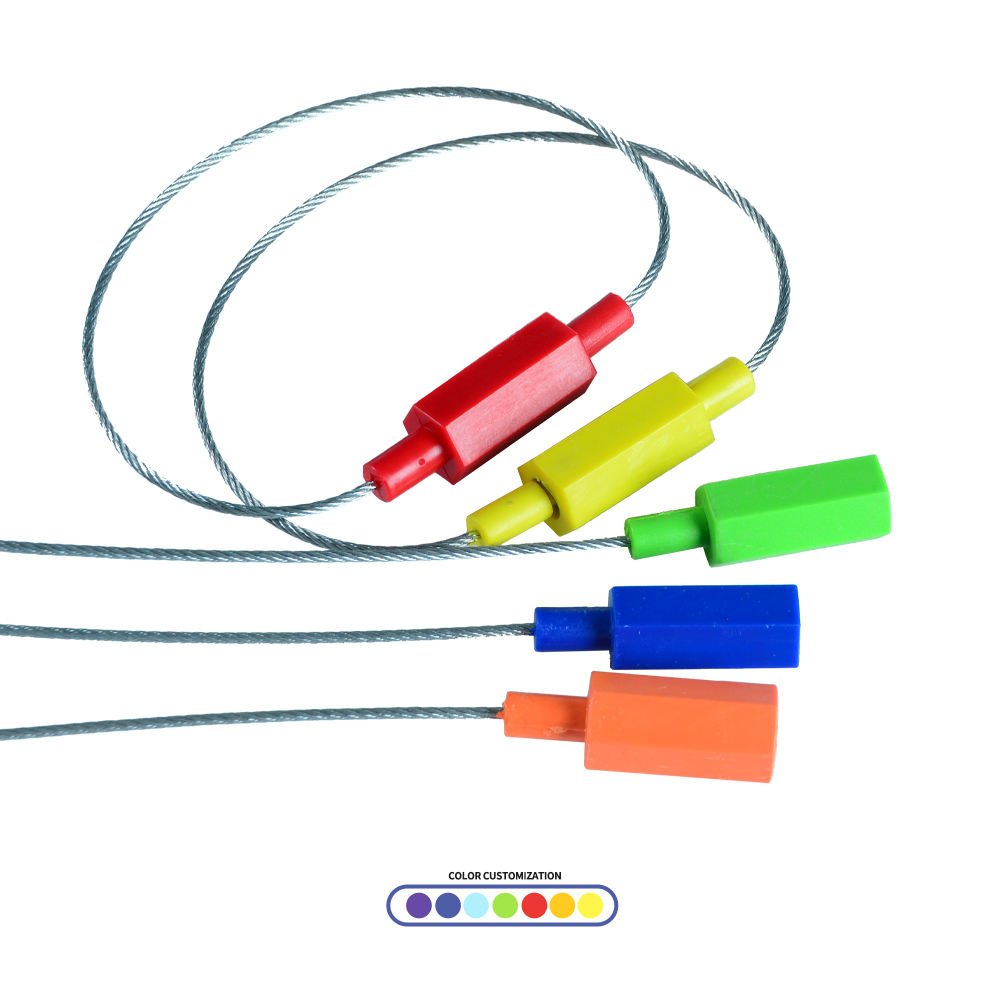

Customizable Options

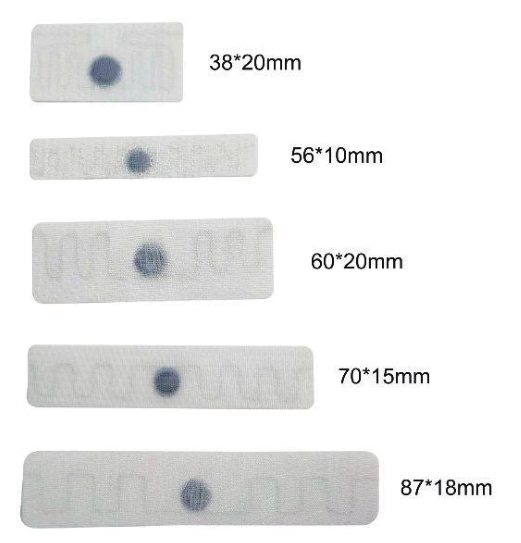

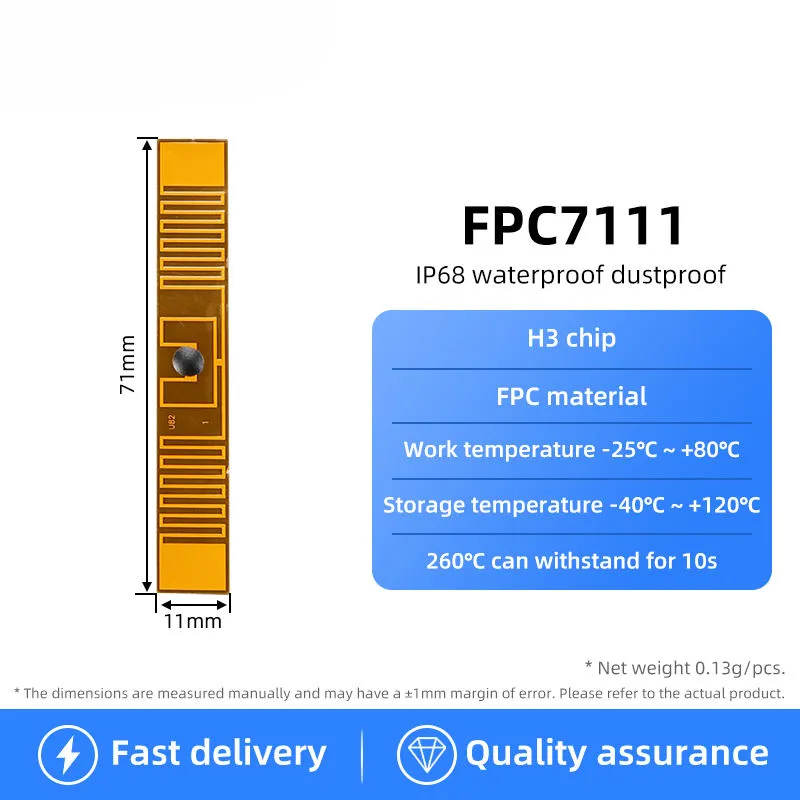

4. Technical Specifications

| Parameter | Details |

|---|---|

| Frequency Range | UHF 860–960 MHz |

| Protocols | EPCglobal Class 1 Gen2 / ISO 18000-6C |

| Read Range | 3–6 meters (depending on reader and environment) |

| Washability | 200+ wash/sterilization cycles |

| Chip Options | Impinj Monza, NXP UCODE, Alien Higgs |

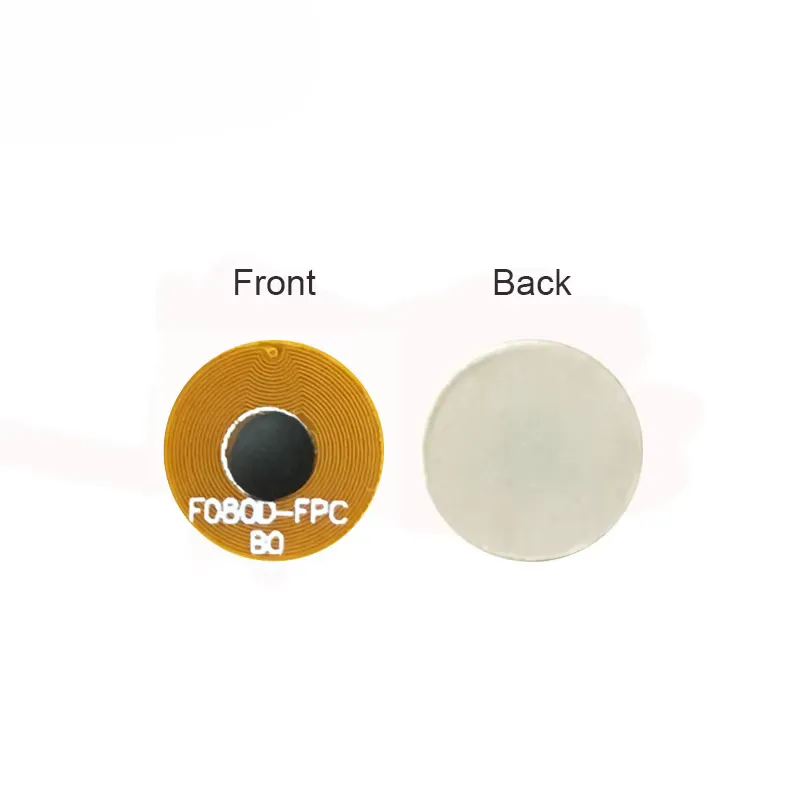

| Material | Textile / PPS / Epoxy encapsulation |

| Attachment Methods | Sewing, heat-sealing, inserting |

| Operating Temp | -20°C to +200°C |

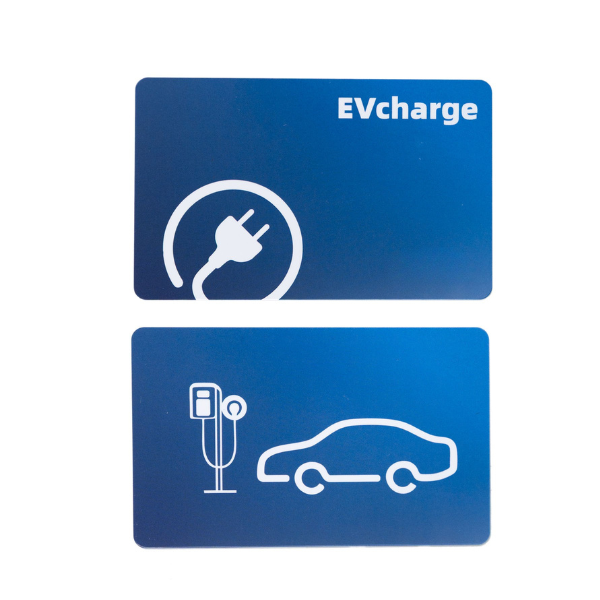

| Applications | Hotels, hospitals, uniforms, industrial laundries, apparel management |

5. Advantages Over Standard Tags

-

Specifically designed for textiles – soft, flexible, and durable.

-

Survives industrial laundry processes – heat, water, chemicals.

-

Simultaneous reading – hundreds of tags scanned at once.

-

Lifecycle insights – manage usage and replacement efficiently.

-

Reduced theft and loss – traceable items at all times.

6. Applications

-

Hotels – bed sheets, towels, and staff uniforms.

-

Hospitals – patient gowns, surgical uniforms, and sterile linens.

-

Industrial Laundries – large-scale garment and textile tracking.

-

Apparel Management – uniforms and rental clothing.

-

Event & Entertainment – costumes and textile assets.

7. Customization Options

-

Chip type and memory size.

-

Printing with logo, serial, or barcode.

-

Shape, size, and material selection.

-

Pre-encoding with customer database integration.

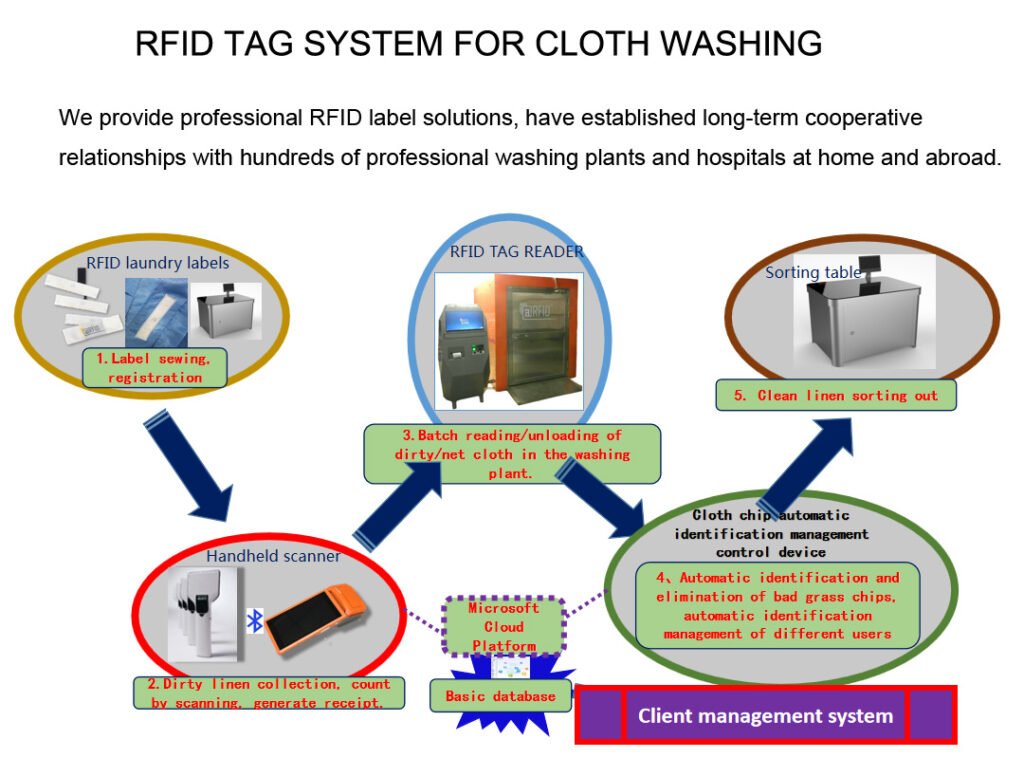

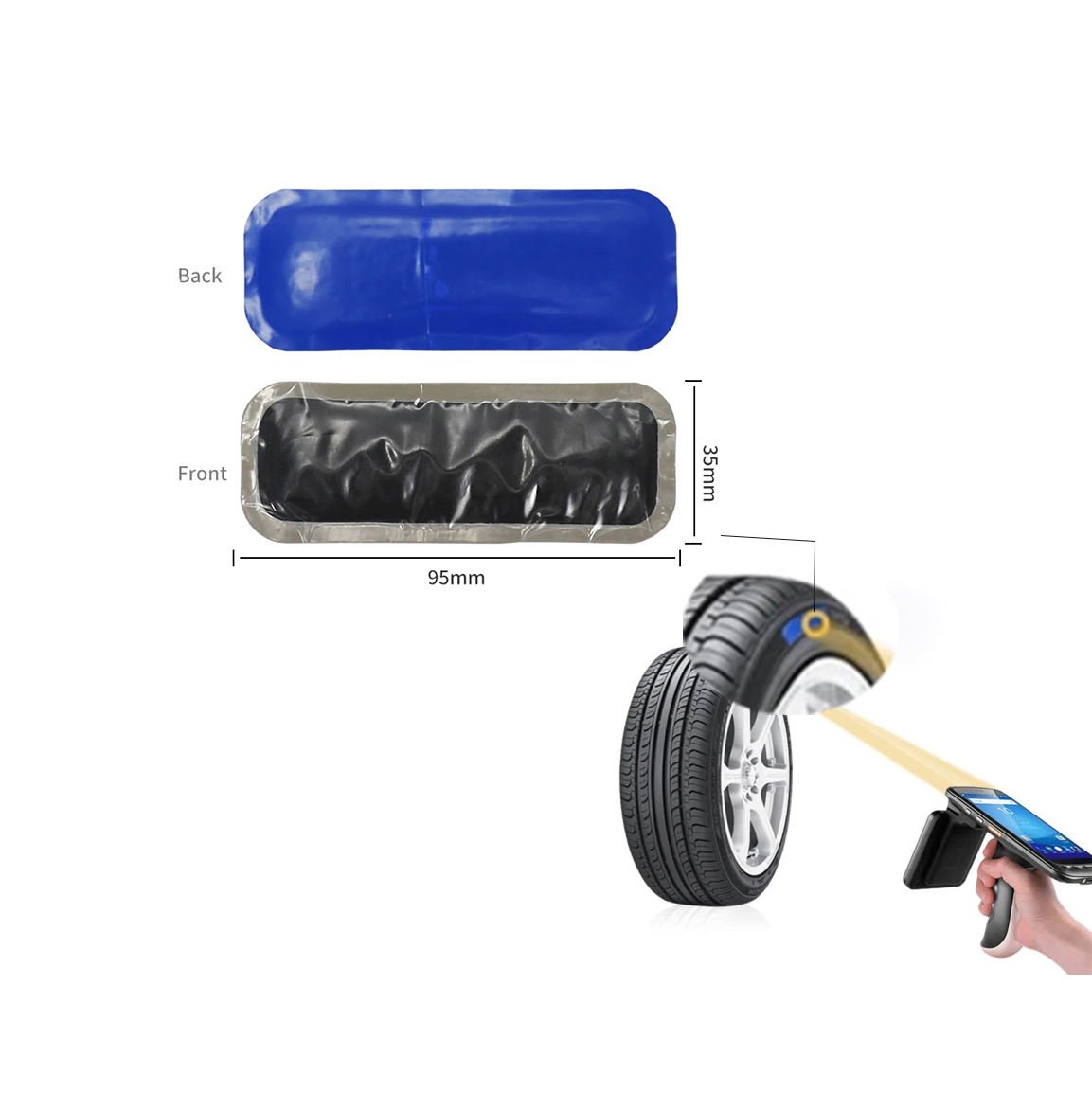

8. Installation & Deployment

-

Sew or heat-seal tag into linen or garment.

-

Program unique ID for tracking in ERP/WMS systems.

-

Use UHF readers to scan bulk items at laundry checkpoints.

-

Monitor usage cycles, distribution, and losses in real-time.

9. Frequently Asked Questions (FAQ)

Q1: How many wash cycles can the tags survive?

Typically 200+ washes depending on process conditions.

Q2: Are they comfortable in apparel?

Yes, tags are soft and flexible when embedded in textiles.

Q3: Can tags be scanned in bulk?

Yes, UHF RFID allows simultaneous reading of hundreds of items.

Q4: What standards are supported?

EPC Gen2 / ISO18000-6C for global compatibility.

Q5: What industries benefit most?

Hotels, hospitals, laundries, apparel rental, and textile management.

10. Conclusion

The UHF Textile Apparel RFID Laundry Tag is a durable, washable, and efficient solution for managing hotel, hospital, and industrial laundry operations. With long-range readability, lifecycle tracking, and resistance to harsh washing processes, it enables businesses to improve efficiency, reduce losses, and ensure better linen management.