RFID Apparel & Retail Inventory Management Application

Introduction

The apparel and retail industry has undergone tremendous transformation in the past decade, driven by fast fashion, omni-channel sales, and rising customer expectations for instant product availability. Traditional barcode-based inventory systems often fail to deliver the accuracy, speed, and visibility required to compete in this digital-first environment.

RFID technology (Radio Frequency Identification) enables retailers to move beyond manual stock counts and delayed updates by providing real-time inventory visibility, accurate item-level tracking, and seamless integration across online and offline sales channels. Whether it is tracking thousands of apparel items in a flagship store, managing seasonal promotions, or preventing shrinkage at the checkout counter, RFID ensures retailers gain end-to-end control of their supply chain.

This solution page explores how RFID can be applied to apparel and retail inventory management, from store-level replenishment to customer engagement.

Why Choose RFID Apparel & Retail Inventory Management Application

RFID provides a competitive advantage that barcodes cannot match:

- Up to 99% Inventory Accuracy: Automated item-level tracking ensures stores know exactly what is in stock, in the fitting room, or sold.

- Faster Stock Counts: Staff can scan thousands of items in minutes using handheld RFID readers.

- Reduced Out-of-Stocks: Real-time replenishment ensures shelves are always stocked with best-selling SKUs.

- Omnichannel Fulfillment: Accurate inventory data allows “Buy Online, Pick-up In Store” (BOPIS) and ship-from-store operations.

- Shrinkage Control: RFID-enabled EAS (Electronic Article Surveillance) prevents theft and loss.

- Customer Engagement: Smart fitting rooms and interactive displays enhance the shopping experience.

Application Scenarios

Real-time Stock Visibility & Store Replenishment

Inventory in fashion retail is notoriously difficult to manage. Seasonal changes, fast-moving styles, and fragmented supply often cause stock-outs on the sales floor while overstock remains in the backroom. Barcode-based systems cannot keep pace since each item must be scanned manually, making counts slow and error-prone.

RFID solves this by giving each garment a unique digital identity. Staff can wave a handheld reader across shelves or racks and instantly update stock levels. When items run low on the sales floor, the system triggers alerts to replenish from the backroom. Store associates can now complete a full-cycle stock count in under 30 minutes, compared to several hours with barcodes.

Key Benefits:

Near-perfect stock accuracy (98–99%).

Increased sales from fewer “empty shelf” scenarios.

Staff productivity redirected from counting to customer service.

Customers find the right size and color in-store, improving satisfaction.

Omnichannel Fulfillment (BOPIS & Ship-from-Store)

Omnichannel is no longer optional. Customers expect to buy online and pick up in-store (BOPIS), or have products shipped from the nearest retail outlet. Yet many retailers cancel orders due to inaccurate inventory data, damaging trust.

RFID enables real-time visibility across every channel. When an online order is placed, the system instantly confirms if the item is available in-store or in the backroom. Staff pick the item, scan it via RFID, and prepare it for customer pickup or courier dispatch. This not only reduces order cancellations but also speeds up last-mile delivery.

Key Benefits:

Higher order fulfillment rate.

Reduced lost sales from “phantom inventory.”

Faster delivery, improving customer loyalty.

Stores function as efficient mini-distribution centers.

Smart Fitting Rooms & Customer Experience

The fitting room is the most influential space in apparel retail. Studies show that 67% of purchase decisions are made after trying on an item. RFID makes this stage intelligent and interactive.

When a shopper brings items into a smart fitting room, RFID readers automatically identify them. A smart mirror screen displays product details, available sizes, color variants, and suggestions for matching items. If the customer wants another size, they can request staff assistance via the mirror without leaving the room.

Key Benefits:

Boosts cross-selling and upselling opportunities.

Reduces lost sales due to missing sizes or colors.

Provides customers with an elevated, high-tech shopping experience.

Collects valuable data on items frequently tried but not purchased.

Supply Chain & Warehouse Integration

Inventory accuracy issues often start before products even reach the store. Shipment errors, delays, and lack of visibility in distribution create downstream chaos.

By tagging apparel items at the source (factory), retailers ensure visibility across the supply chain. Distribution centers equipped with RFID gates verify shipments automatically as pallets pass through dock doors. This eliminates mismatched deliveries and speeds up cross-docking operations.

Key Benefits:

Automated shipment verification reduces receiving time by 80%.

Vendor compliance improves with RFID-tagged goods.

Faster replenishment cycles ensure stores never run out of bestsellers.

Full traceability from production to store shelf.

How It Works: Deployment Process

- Tagging & Encoding – Attach RFID tags to apparel items at source (factory or distribution center). Encode EPC (Electronic Product Code) data.

- In-store Readers Setup – Install handheld readers, fixed antennas, and fitting room RFID sensors.

- Integration with POS & ERP – Connect RFID system with retail POS and ERP systems for real-time synchronization.

- Staff Training & Go-live – Train store associates on RFID use and conduct a phased rollout.

- Ongoing Analytics – Use dashboards for inventory control, replenishment, and customer analytics.

Specifications

| Parameter | Specification |

|---|---|

| RFID Standard | EPC Class 1 Gen 2, ISO 18000-6C |

| Frequency | UHF 860–960 MHz (Global) / HF 13.56 MHz (NFC for customer interaction) |

| Read Range | Up to 10m with fixed readers, 2–5m with handheld devices |

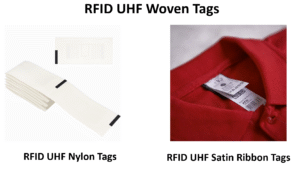

| Tag Form Factors | Hang tags, woven labels, stickers, hard tags |

| Durability | Washable, tamper-resistant, eco-friendly options |

| Integration | Compatible with POS, ERP, WMS, and CRM systems |

| Applications | Apparel tracking, omnichannel fulfillment, loss prevention, smart fitting |

FAQ

How does RFID improve retail inventory accuracy?

Q2: Can RFID work with both online and offline retail systems?

Q3: Are RFID tags reusable in apparel?

Q4: Does RFID reduce theft in retail stores?

Recommended Products

Tamper-Proof Jewelry RFID UHF Tag – Custom-Shaped PVC Passive Label for Jewelry Tracking & Anti-Counterfeiting

Custom Shaped Waterproof Mini Security Tracking RFID UHF Label | Passive Tamper-Proof Jewelry Labels

Reusable NFC RFID Sticker Tag – 10mm Mini Rewritable NFC Chip Label (Free Sample Available)

ISO 18000-6C UHF RFID Inlay – 860–960MHz Writable Passive RFID Label & Tag Sticker

Factory Customized UHF RFID Inlay Sheet – Long Range Passive Prelaminated RFID Label Sticker with UHF Chip

Get A Quote

Tell us about your project, and we’ll recommend the best RFID tags, readers, and software tailored to your retail needs. Fast response within 24 hours from our RFID experts.