RFID Warehouse Management & Supply Chain Solution

Subtitle: Optimizing Warehouse Operations with RFID: Real-Time Visibility, Faster Logistics, and Smarter Supply Chain Management

Introduction

Warehousing and supply chain management are the backbone of global commerce. Every product, from consumer goods to automotive parts to pharmaceuticals, passes through warehouses, distribution centers, and supply chain nodes before reaching end customers. As e-commerce continues to accelerate and customer expectations for same-day or next-day delivery rise, warehouses face increasing pressure to improve speed, accuracy, and efficiency while reducing operational costs.

Traditional warehouse management systems (WMS) and barcode-based processes, while reliable, are not designed for the complexity and scale of modern logistics. Barcode systems require line-of-sight scanning and manual handling of each individual item. This creates bottlenecks in receiving, counting, and shipping, leading to errors, inefficiencies, and a lack of real-time visibility.

Radio Frequency Identification (RFID) provides a powerful solution to these challenges. By embedding each item, pallet, or container with a unique RFID tag, warehouses gain the ability to automatically capture data in real time without line-of-sight. Fixed RFID readers at dock doors, conveyors, and shelves can monitor the movement of goods instantly, while handheld readers allow staff to scan thousands of items in minutes.

The RFID Warehouse Management & Supply Chain Solution integrates hardware, software, and analytics into a seamless platform, enabling:

Real-time inventory accuracy up to 99%.

Labor savings by automating scanning processes.

Reduced errors in receiving, picking, and shipping.

Enhanced visibility across the entire supply chain.

Improved customer satisfaction through faster, more reliable order fulfillment.

This solution is designed for industries including e-commerce fulfillment, retail distribution, automotive supply chains, pharmaceuticals, food & beverage, and cold chain logistics. Whether managing a small warehouse or a global supply network, RFID transforms supply chain operations from reactive to proactive, from manual to automated, and from opaque to transparent.

Why Choose RFID in Warehouse & Supply Chain Management

2.1 Real-time Visibility

With RFID, every tagged item or pallet is visible at all times. When goods move from inbound receiving to storage, then to picking, packing, and outbound, the system automatically updates inventory records. Managers can see where each SKU is located and whether it is available, reserved, or shipped. This real-time view eliminates “phantom inventory” and reduces lost or misplaced stock.

2.2 Increased Inventory Accuracy

Barcodes typically deliver 65–80% accuracy in warehouse environments, depending on labor compliance. RFID raises accuracy to 98–99%, reducing stock discrepancies and enabling precise replenishment. This directly improves order fulfillment rates and reduces backorders.

2.3 Labor Efficiency

RFID automates scanning tasks. Workers no longer need to handle and scan each item individually. Instead, RFID portals can scan hundreds of items in bulk as they pass through, while handheld readers can cover thousands of items during cycle counts. This frees staff to focus on value-added activities.

2.4 Faster Inbound & Outbound Processing

Inbound trucks can be unloaded and verified in minutes using RFID dock portals. Outbound shipments are automatically validated to ensure the correct items are loaded. This accelerates warehouse throughput and reduces detention costs.

2.5 Reduced Picking & Packing Errors

Order picking is a critical step where errors can damage customer satisfaction. RFID-enabled smart carts, pick-to-light systems, and tunnel readers verify each pick and pack automatically, ensuring error-free fulfillment.

2.6 Theft & Loss Prevention

RFID tags provide item-level visibility that deters theft and prevents misplacement. Unauthorized removals can be flagged instantly at exits, while shrinkage is reduced by monitoring goods across every movement.

2.7 Data-Driven Insights

Every RFID scan generates data that can be analyzed for trends and optimization. Managers can identify bottlenecks, evaluate supplier compliance, measure worker productivity, and forecast demand more accurately.

Application Scenarios

Inbound Logistics & Receiving

Challenges:

Traditional inbound processes require manual barcode scanning of each case or pallet, which is time-consuming and prone to human error. Shipments may contain shortages, overages, or mis-labeled goods that go undetected until later, disrupting downstream processes.

RFID Solution:

RFID tags are applied at the manufacturer or supplier level.

As trucks arrive at the warehouse, RFID portals at dock doors automatically read all tagged items as they pass through.

The system instantly verifies shipments against Advanced Shipping Notices (ASN).

Any discrepancies (missing or extra items) are flagged immediately.

Benefits:

Receiving time reduced by up to 80%.

Accurate verification without manual scanning.

Reduced bottlenecks and faster truck turnaround.

Full compliance and accountability across suppliers.

Example:

In a large retail distribution center, inbound trucks carrying thousands of RFID-tagged apparel items are processed in minutes. Dock door portals read entire shipments automatically, reducing labor costs and ensuring inventory accuracy before items enter the warehouse.

Inventory Management & Cycle Counting

Challenges:

Cycle counts and annual stocktaking are labor-intensive with barcodes. Workers must scan each item manually, often requiring temporary shutdowns. This results in poor accuracy and increased operational costs.

RFID Solution:

Handheld RFID readers allow staff to scan thousands of items per hour without line-of-sight.

RFID drones or robots can automate cycle counts by scanning items across aisles.

Smart shelves with embedded RFID readers provide continuous monitoring.

Benefits:

Inventory accuracy improved to 98–99%.

Cycle counts completed in hours instead of days.

Reduced need for full shutdowns during stocktaking.

Real-time updates keep WMS accurate at all times.

Example:

A pharmaceutical warehouse achieves near-perfect inventory accuracy by using RFID handheld readers for weekly cycle counts. Staff scan entire aisles in minutes, eliminating discrepancies and ensuring compliance with regulations.

Order Picking & Packing

Challenges:

Order picking is the most labor-intensive and error-prone process in warehouses. Manual barcode systems require workers to scan each item, which slows down operations and introduces mistakes that lead to returns and dissatisfied customers.

RFID Solution:

RFID-enabled smart carts guide workers with visual or audio cues.

Items are automatically verified as correct when placed in the cart.

Tunnel readers at packing stations validate entire orders at once.

The system ensures each carton contains exactly the right SKUs.

Benefits:

Picking accuracy increased to 99.9%.

Significant reduction in returns and re-shipments.

Improved customer satisfaction from error-free orders.

Faster throughput and higher labor productivity.

Example:

An e-commerce fulfillment center uses RFID carts to support same-day delivery. Workers are guided through the warehouse, and RFID readers confirm each item in real time. Packing tunnels verify completed orders, ensuring customers receive exactly what they ordered.

Outbound Logistics & Shipping

Challenges:

Incorrect or incomplete shipments are costly and damage customer trust. Manual barcode scans may miss errors, while outbound processing often creates bottlenecks at dock doors.

RFID Solution:

RFID portals at outbound doors automatically verify shipments as they leave.

Forklifts with RFID readers ensure pallets are loaded onto the right truck.

Shipping documentation and WMS are updated instantly.

RFID tags provide traceability for goods in transit.

Benefits:

Outbound errors reduced by 90%+.

Faster truck loading and dispatch.

Improved traceability and accountability across supply chain.

Enhanced customer satisfaction with on-time, error-free deliveries.

Example:

An automotive parts warehouse installs RFID portals at outbound docks. Each pallet is verified against the shipping order automatically, preventing costly shipping errors. This reduces penalties from OEM customers and ensures production lines receive the correct parts on time.

How It Works: Deployment Process

The end-to-end workflow of RFID-enabled warehouse management typically follows these steps:

Tagging & Encoding – Items are tagged at manufacturing or upon arrival. Each tag contains EPC (Electronic Product Code) data.

Inbound Receiving – Dock portals read tags in bulk as shipments arrive. WMS verifies ASNs automatically.

Storage & Put-away – RFID readers update item locations in real time as goods are stored.

Inventory Management – Handheld devices and smart shelves continuously track stock.

Order Picking – Workers guided with RFID smart carts or wearables pick items with instant validation.

Packing Verification – Tunnel readers confirm each order is accurate before sealing.

Outbound Shipping – RFID portals and forklifts verify outbound shipments.

Returns Handling – Returned goods are scanned, verified, and updated back into inventory.

RFID Components in Warehouse Solutions

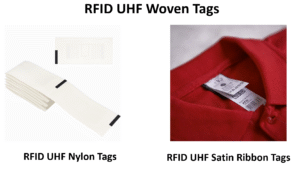

Tags

- UHF passive labels for cartons.

- Rugged tags for pallets.

- Metal-mount tags for machinery.

- Sensor tags for cold chain.

Readers

- Fixed readers for dock doors.

- Handheld readers for staff.

- Tunnel readers for conveyors.

- Vehicle-mounted readers for forklifts.

Software

- RFID middleware integrates devices.

- WMS and ERP integration via APIs.

- Analytics dashboards for KPIs and insights.

Specifications

| Component | Specification |

|---|---|

| Frequency | UHF 860–960 MHz (EPC Gen2 ISO18000-6C) |

| Read Range | 1–15m depending on reader type |

| Tag Memory | EPC 96–512 bits; User Memory up to 8 KB |

| Read Speed | Hundreds of tags per second |

| Durability | Tags withstand -40°C to +85°C, IP67 rating |

| Integration | Compatible with WMS, ERP, TMS, IoT platforms |

| Security | Encrypted data, anti-cloning features |

FAQ

Q1: How long does it take to implement an RFID warehouse solution?

Q2: Are RFID tags reusable?

Q3: Does RFID work in all warehouse environments?

Q4: How does RFID integrate with existing WMS?

Q: Is data secure in RFID animal tracking?

Recommended Products

RFID UHF Carrier Tag – Unlimited Read & Write Fujitsu ISO15693 Industrial RFID Tag for Small Pallets, Logistics & Smart Manufacturing

Industry 4.0 RFID Tag – High-Frequency 30mm Industrial Code Carrier for Automation, Smart Factory, and Manufacturing Execution Systems (MES)

UHF On-Metal Label RFID Tag (Silverline Printable) for Asset Tracking – NFC & RAIN UHF Labels

Anti-counterfeiting Tamper-proof Disposable NFC RFID Labels – Fragile Breakable Smart Label for Wine Bottles, Liquor Packaging, Cosmetics & Brand Protection

Reusable NFC RFID Sticker Tag – 10mm Mini Rewritable NFC Chip Label (Free Sample Available)

ISO 18000-6C UHF RFID Inlay – 860–960MHz Writable Passive RFID Label & Tag Sticker

Get A Quote

Ready to transform your warehouse with RFID? Contact us today for a customized solution and fast quotation.