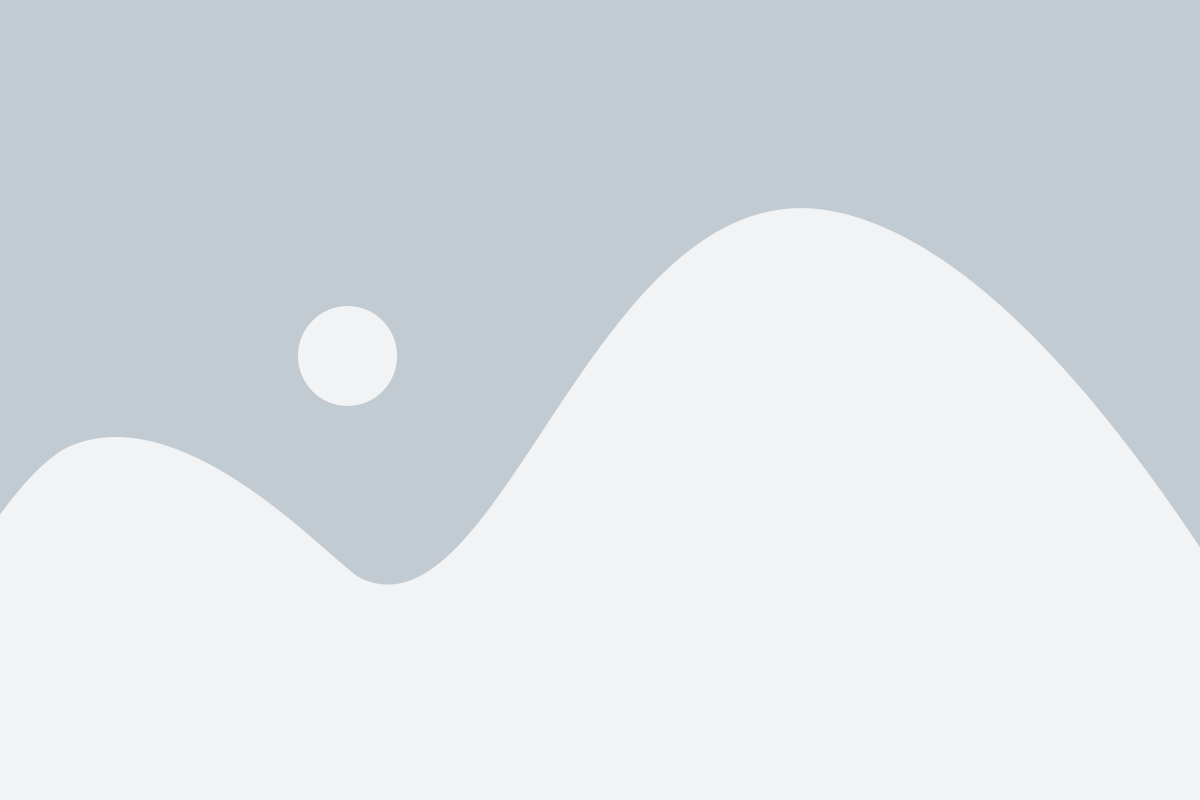

“Last week, we found 200 shirts missing during the audit. The system said they were in stock, but they were nowhere to be found!” This isn’t just a headache for one factory owner—it is the most common complaint we’ve heard during our 5 years in the RFID clothing tag industry. At FYRFID, after serving over 100 garment businesses worldwide, we’ve learned that inaccurate inventory is a “silent thief” stealing your profits. The Cost of Living with Low Accuracy:

When your inventory accuracy stays below 85%, your business suffers three major “bruises”:

- Lost Sales: In places like Buenos Aires, retailers tell us: “Our shelves are empty, but our warehouse is full of last season’s leftovers.” This mismatch causes a 3-5% loss in annual revenue.

- Wasted Labor: A factory owner in Bogotá complained that every audit requires the entire staff to work two days of overtime, paralyzing the production line.

- Broken Trust: Shipping errors in Santiago lead to double the industry average in complaints. As labor costs rise, manual counting just can’t keep up.

The Solution: Our professional RFID clothing tags act like a “high-speed radar” for your stock.

- Mass Counting: Read 200+ items in seconds with 99.9% accuracy.

- Total Visibility: Track a garment from the sewing machine to the store shelf.

- Smart Alerts: Get “Low Stock” warnings based on real-time data.

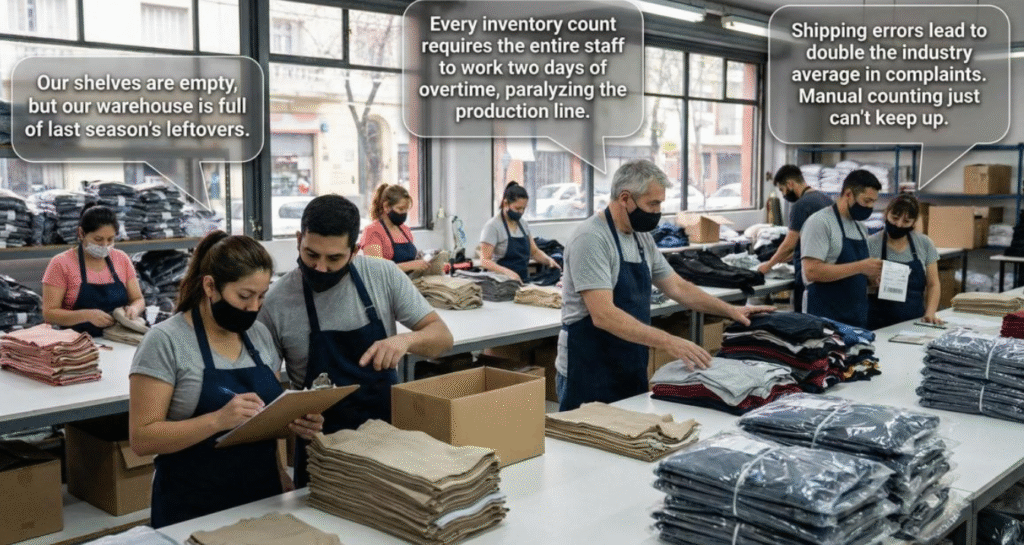

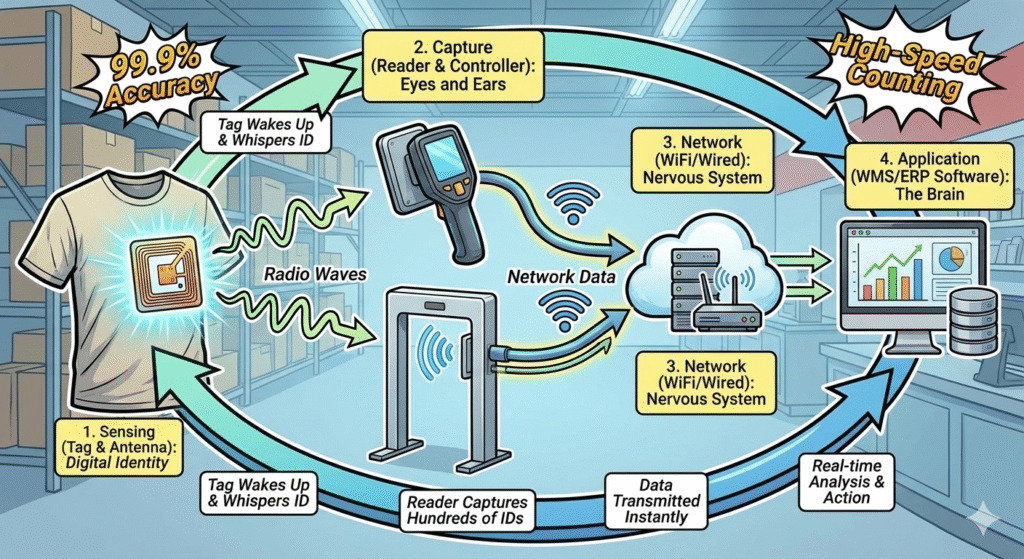

1. How RFID Garment Tag Works: Giving Every Garment a “Digital Identity.”

Think of an RFID system as giving every shirt its own Digital ID Card. Inside each tag is a tiny chip with a unique code. When our reader sends out a radio wave, the tag “wakes up” and whispers its ID back. Our advanced “anti-collision” tech allows the reader to hear hundreds of these whispers at once without getting confused.

1.1 The 4-Layer “Brain” of the RFID System

| Layer | Components | Role | Performance Goal |

| Sensing | Tags & Antennas | The “Digital DNA” | Read range of 3-10 meters |

| Capture | Readers & Controllers | The “Eyes and Ears” | Processes 500+ tags per second |

| Network | WiFi 6 / Wired | The “Nervous System” | Ultra-low delay (<10ms) |

| Application | WMS/ERP Software | The “Brain” | Real-time data analysis |

1.2 Digitizing the Supply Chain (Application Scenarios & Quantitative Benefits)

| Operational Stage | Core Application & Functionality | Quantitative Benefits & Validation |

| Precision Production Control | • Process Binding: RFID tags are implanted during the cutting stage to give every fabric piece a unique identity. • Transparency: Automatically records time nodes and personnel for sewing, printing, and QC. • Smart Alerts: Monitors production rhythm and triggers alerts for delays or quality issues. | • Production cycle shortened by 25% (verified by Bogotá factory project). • 100% Work-in-Progress (WIP) visibility, reducing communication costs by 70%. • 90% reduction in manual labor for data collection and reporting. |

| Logistics & Warehousing Revolution | • High-Speed Receiving: Cartons pass through RFID gates for automatic counting and SKU verification without opening boxes. • Real-time Inventory: Handheld devices enable “walking audits” that sync stock data instantly. • Smart Sorting: Systems guide picking paths and auto-check outbound goods to ensure order accuracy. | • Receiving efficiency increased from 200 pcs/hr to 600 pcs/hr. • Inventory accuracy increased from 85% to 99.9% (verified by 3rd-party audit). • Shipping error rate dropped from 3% to <0.1%, significantly cutting return costs. |

| Smart Retail Operations | • Intelligent Shelf Management: Shelves sense how often items are picked up or taken to fitting rooms. • Data-Driven Restocking: Generates replenishment suggestions based on real-time fitting-to-sales conversion data. • Consumer Insights: Collects interaction data to optimize design, selection, and display. | • Stockout rates lowered by 65%, directly boosting sales revenue. • 99% store inventory visibility, reducing staff search time by 80%. • Best-seller prediction accuracy increased by 40% based on fitting room data. |

1.3 Real-World Benefits: From Factory to Store

- Production: We saw a factory in Bogotá shorten its production cycle by 25% by tracking pieces at the sewing stage.

- Logistics: Receiving efficiency jumped from 200 to 600 pieces per hour. It’s like switching from a flashlight to a floodlight—you see everything instantly.

- Retail: Out-of-stock rates dropped by 65%. If a customer tries on a dress but doesn’t buy it, the system knows, helping you understand fashion trends better.

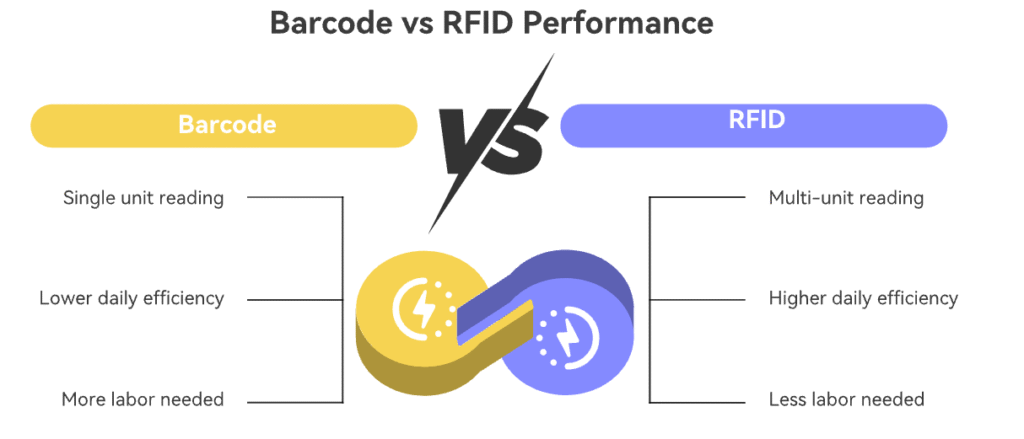

Efficiency Comparison (Traditional Barcode vs. RFID)

| Performance Metrics | Traditional Barcode Scanning | RFID Technology | Improvement Magnitude |

| Batch Reading Quantity | 1 unit at a time | 200 – 500 units | 500x Faster |

| Daily Inventory Efficiency | 5,000 units / 8 hours | 50,000 units / 2 hours | 10x Efficiency |

| Labor Requirement | 3 Dedicated staff members | 1 Part-time inspector | 67% Cost Saving |

2. Key RFID Tag Technical Specs: What Every Manager Needs to Know

To ensure your tags last as long as your clothes, you must focus on three “Vital Signs”:

2.1 Durability: Can it survive the wash?

Apparel environments are tough. Our lab tests categorize durability as:

| Grade | Testing Standard | Best Use Case |

| Grade A | 200+ Industrial Laundry Cycles | Workwear, School Uniforms, Hotel Textiles |

| Grade B | 100+ Home Washing Cycles | Standard Ready-to-Wear, Denim Collections |

| Grade C | 50+ Dry Cleaning Cycles | High-end Fashion, Wool Products |

FYRFID Fact: Our wash labels used by major workwear brands maintain a 99.5% read rate even after 200 industrial cycles.

2.2 Environmental Strength: Built for South America

| Climate Type | Standard | Performance Guarantee |

| Amazon (Hot/Humid) | IP68 Waterproof | Works at 95% humidity; signal stays strong. |

| Andes (Cold/Dry) | -25°C to +85°C | Stable reading even in high-altitude dry heat. |

| Coastal (Salty) | Anti-Corrosion | Tags survive salty sea air and dust. |

2.3 Core Performance Indicators

Optimizing antenna design and chip selection ensures peak reading accuracy and efficiency.

| Parameter | Standard Requirement | Optimization Target | Testing Method |

| Read Range | 3 – 5 meters | 8 – 10 meters | EPC Global Standard |

| Read Rate | 500 tags/sec | 2,000 tags/sec | Multi-tag Test |

| Accuracy | 99% | 99.9% | 72-hour continuous test |

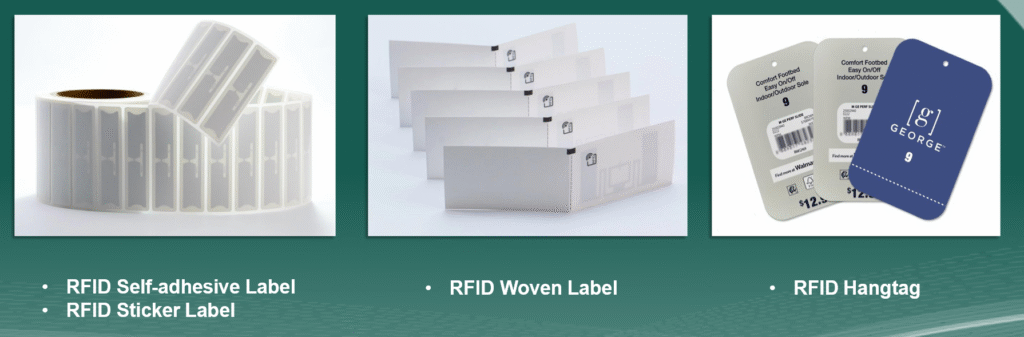

3. Product Selection: Which RFID Garment Tag is Right for You?

Choosing the wrong tag is like putting truck tires on a race car—it just won’t work. For managers, technical terms (such as UHF) ultimately translate into specific products. Choosing the wrong tag format can, at best, lead to reading failures and, at worst, affect product appearance or increase unnecessary costs. Our core recommendation is: UHF technology is the foundation of warehouse management, but different product formats are required to adapt to different stages of the process.

The following is a selection guide for the three mainstream product formats based on your factory’s actual workflow:

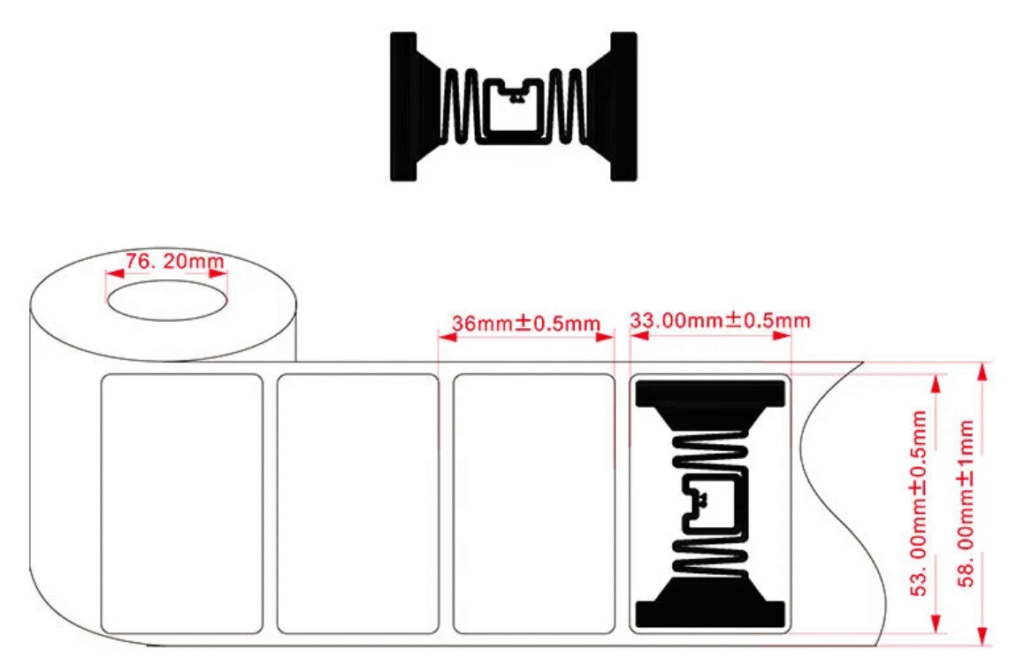

3.1. RFID Adhesive Labels: The Efficiency Engine for Logistics and Warehouse Management

Adhesive labels are the top choice for fast labeling and high-speed reading, especially suitable for outer boxes, packaging bags, and garment hang tags that require post-production labeling.

- Core Advantages & Scenarios:

- High-Speed Operation: When used with automatic labeling machines, they can achieve labeling efficiency of hundreds of pieces per minute, perfectly suited for high-speed stages such as receiving and sorting.

- Flexible Application: Can be directly pasted on various surfaces, making it an ideal choice for integrating with existing paper documents or packaging.

- Performance Keys: Read distance and stability primarily depend on antenna design and chip performance. For example, the 70*14mm (Belt series) antenna mentioned in the documents is optimized for long-range reading, while the 42*16mm (Miniweb series) is suitable for space-constrained environments.

- Management Decision Points:

- Chip Selection: Choose based on data capacity requirements. For instance, NXP UCODE 8 (128-bit EPC) can store more information, while Monza M750 (96-bit EPC + 32-bit User Memory) allows for custom data writing.

- Adhesive Selection: It is crucial to choose between a removable adhesive (to avoid damaging garments when applied directly) or a permanent adhesive (for boxes or hang tags to ensure a secure bond) based on the application surface.

- ARC Certification: If your customers are international brands like Walmart, selecting antennas that have passed ARC certification (such as AD-334, AD-327) is a prerequisite for project success.

3.2. RFID Washable Labels (Woven Labels): The Solution for Seamless Integration and Extreme Durability

Washable labels are sewn directly into the clothing, becoming a part of the product. They are the ultimate solution for single-item full lifecycle management, particularly suitable for high-end apparel and workwear requiring frequent washing.

- Core Advantages & Scenarios:

- Permanent Identification: From the production line to the retail store, and even after multiple washes by the consumer, the tag remains integrated with the garment, eliminating the risk of falling off.

- Aesthetic & Stealthy: Integrates perfectly with traditional care labels without affecting the garment’s appearance, maintaining brand quality.

- Superior Durability: Uses materials like coated nylon tape or polyester tape, featuring high-temperature and wash-resistant properties. They can withstand over 200 industrial wash cycles, with a lifespan synchronized with the garment itself.

- Management Decision Points:

- Customized Services: Can be customized with single-color/multi-color printing and variable data encoding according to your needs. Supports delivery in rolls or single pieces to flexibly adapt to your production line.

- Cost Considerations: Although the unit price is higher than adhesive labels, its permanent nature avoids secondary costs caused by tags falling off during circulation, potentially resulting in a lower Total Cost of Ownership (TCO).

3.3. RFID Hang Tags: The Bridge Between Retail Experience and Inventory Management

Hang tags are the key carrier connecting efficient warehouse management with smart retail stores. They can carry UHF chips to satisfy warehouse inventory needs and can also integrate NFC chips to provide interactive experiences for consumers.

- Core Advantages & Scenarios:

- UHF for Warehousing: Within the warehouse, UHF chips on hang tags can be read in bulk at high speeds, achieving second-level inventory audits.

- NFC for Interaction: In stores, consumers can touch the NFC area of the hang tag with their phones to access product stories, authenticity verification, and styling recommendations, enhancing the shopping experience.

- Flexibility & Cost-Effectiveness: As an attachment, hang tags do not damage the garment itself and can be recycled and reused, keeping costs controllable.

- Management Decision Points:

- Material & Craftsmanship: We provide various material choices such as 200g/250g coated paper or white cardboard, supporting processes like color printing, lamination, and special die-cutting to ensure consistency with your brand image.

- Integration Solutions: UHF adhesive labels can be pasted inside ordinary hang tags, or dedicated RFID hang tags with integrated antennas and chips can be manufactured directly.

3.4 Summary: How to Decide?

| Product Format | Core Application Scenarios | Management Advantages | Performance Focus Points |

| RFID Adhesive Labels | Logistics boxes, packaging bags, and post-production labeling | Fastest deployment, optimal cost, suitable for high-speed automated operations | Antenna size, chip performance, adhesive type |

| RFID Washable Labels | Garments requiring frequent washing, single-item tracking | Permanence, zero detachment, enables full lifecycle management | Washability, high-temperature resistance, and sewing craftsmanship |

| RFID Hang Tags | Connecting warehousing and retail, requiring consumer interaction | Dual-frequency compatibility (UHF+NFC) balances efficiency and experience | Material durability, printing craftsmanship, and chip compatibility |

Final Recommendation: Before project implementation, it is essential to conduct sample testing. We will provide the most suitable tag combination solution and free sampling based on your specific garment fabrics (e.g., down jackets, jeans), warehouse environment, and workflows, ensuring that a 99.9% read accuracy rate is achieved in your actual environment.

4. ROI Analysis: Is RFID Tag Inventory Management System Worth the Investment?

Based on FYRFID’s 5 years of professional experience serving the global apparel industry and industry data, the following figures are derived directly from client project feedback.

4.1 Empirical Data: Quantifying the Value of RFID Investment

| Investment Dimension | Pre-Implementation Status | Post-Implementation Effect | Value Improvement |

| Inventory Accuracy | 92~95% | 99.5-99.9% | Up 21.3% |

| Stocktaking Efficiency | 2,000 pcs/person/day | 20,000 pcs/person/day | Up 900% |

| Labor Costs | 3 people × $500/month | 1 person × $500/month | 67% Saving |

| Stockout Losses | 3.5% of annual sales | 1.2% of annual sales | Reduced by 2.3% |

The payback period for an RFID project is closely related to the scale of implementation. For example, a medium-sized garment enterprise in China invested $45,000 in an RFID system and achieved full cost recovery within 14 months.

4.2 Phase-by-Phase Benefit Analysis: Making Every Cent Visible

Detailed Benefits of RFID Project Implementation Stage

| Implementation Stage | Time Period | Investment Ratio | Main Benefits | Cumulative ROI Rate |

| Pilot Validation | 1-2 Months | 20% of Total Investment | Process optimization; error reduced by 50% | 15-20% |

| Scale Expansion | 3-4 Months | 40% of Total Investment | Efficiency boost; labor cost savings of 30% | 55-60% |

| Full Deployment | 5-6 Months | 40% of Total Investment | Full system optimization; data value extraction | 100%+ |

4.3 Long-Term Value Creation Mechanism

Five-Year Total Cost of Ownership (TCO) Analysis: RFID vs. Barcode

| Cost Item | Traditional Barcode System | RFID System | Five-Year Savings |

| Hardware Investment | $30,000 | $45,000 | -$15,000 |

| Tag Consumables | $50,000 | $75,000 | -$25,000 |

| Labor Costs | $300,000 | $100,000 | +$200,000 |

| Total | $380,000 | $220,000 | +$160,000 |

Based on our extensive industry experience, the marginal cost of an RFID system after three years is nearly zero, whereas traditional systems require continuous high labor investment for stocktaking operations. Through this comprehensive ROI analysis, we help garment enterprises establish a precise understanding of RFID’s value, ensuring that every cent invested delivers a tangible return.

Conclusion

RFID technology is reshaping the inventory management landscape of the apparel industry, achieving end-to-end visualized control from production to sales through precise radio frequency identification. Based on our experience serving over 100 garment companies worldwide, this technology not only raises inventory accuracy to 99.9% and boosts stocktaking efficiency tenfold but also delivers a return on investment within 12-16 months.

Its washability and adaptability to harsh environments ensure long-term stable operation, while intelligent data analysis provides decision support for stockout warnings and best-seller forecasting. We cordially invite you to book a free on-site evaluation to obtain a customized solution, allowing this market-proven technology to become the accelerator for your enterprise’s digital transformation.