Introduction: The Revolution from “Attached” to “Embedded”

In the apparel supply chain, traditional RFID hang tags, while popular, have obvious pain points: they easily fall off during transit or get torn in fitting rooms, leading to a disconnect between “inventory data” and “physical items.”

An increasing number of international brands (such as Uniqlo, Decathlon, and luxury fashion houses) are pivoting from hangtags to RFID Labels. This is not just a change in tag format; it is an efficiency revolution centered on “Source Tagging.” This article will deconstruct every aspect of this “RFID soft label” to help you make the right procurement decisions.

I. RFID System Basics & Product Deconstruction

1.1 RFID 101: How Do RFID Tags Work?

Before diving into RFID woven labels, imagine an RFID Tag as an “Electronic ID with a built-in broadcasting system.”

1.1.1 What is the difference between RFID and Barcodes?

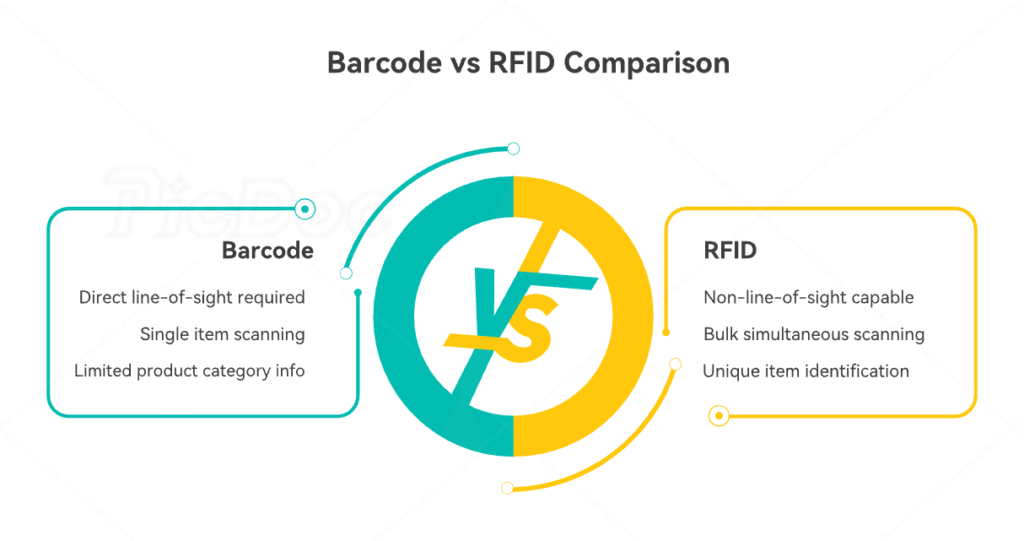

This is the most frequent question from clients. Being an RFID factory, we can summarize it in three points:

- Non-Line-of-Sight Reading: Barcodes are like flashlights; you must aim directly at them to scan. RFID is like a radio; as long as it is within range (typically 3-8 meters), the clothing RFID tags can be captured instantly, even if hidden inside boxes or pockets.

- Bulk Processing: Barcodes must be scanned one by one. An RFID tag reader can scan hundreds of tags per second. This means a stocktaking task that previously took three people a whole day can now be finished in minutes by one person with a handheld reader.

- Uniqueness: A standard barcode only tells the system, “This is a white L-size shirt.” RFID garment tag tells the system, “This is the white L-size shirt with Serial No. 001 from this specific batch.”

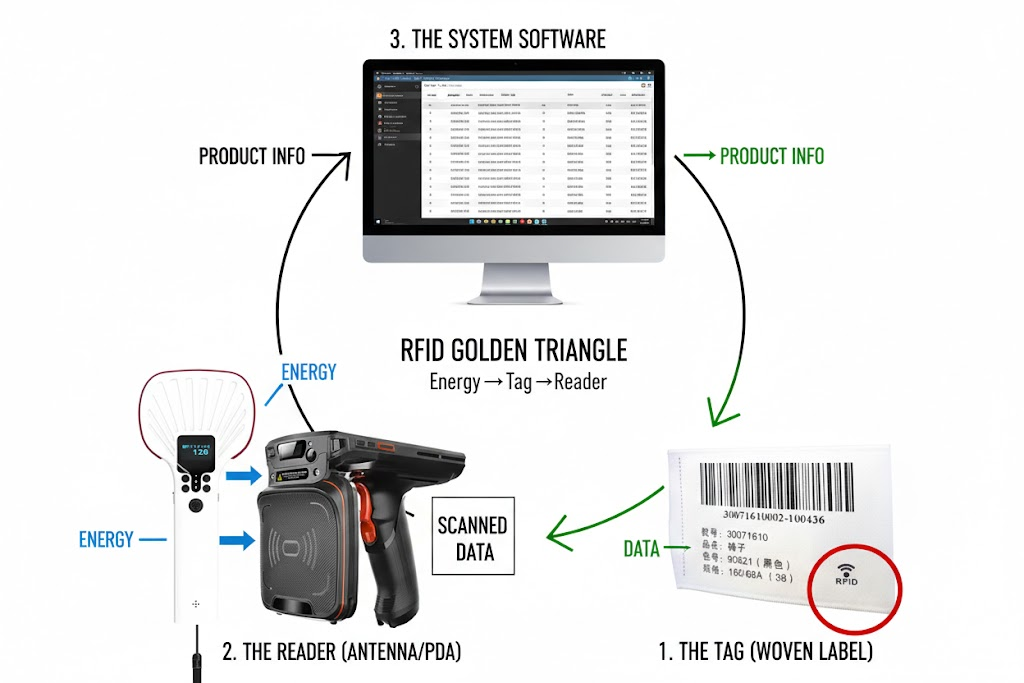

1.1.2. The “Golden Triangle” of RFID Systems

To make RFID work, the tag alone is not enough; it requires three components:

- The RFID Clothing Tag (Woven Label): The data carrier. It has no battery and is powered by the energy received from the reader.

- The RFID Tag Reader (Antenna/PDA): The data collector. It can be a handheld “gun” used by staff or a “portal antenna” at warehouse gates.

- The ERP/MWS Software System: The brain. It converts the scanned numbers into specific product names, colors, and inventory quantities.

1.1.3. About “Frequency”: Why does the apparel industry only talk about UHF?

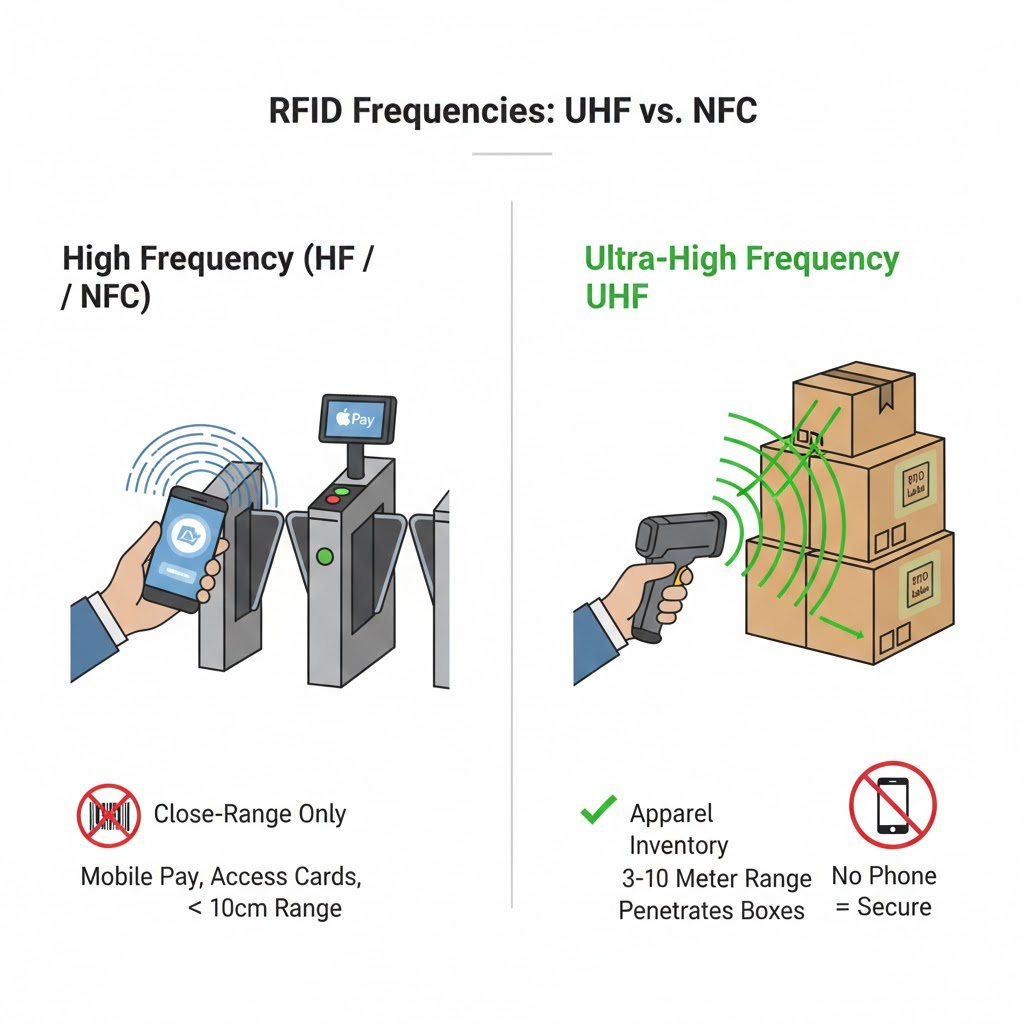

RFID operates across various frequency bands, primarily Low Frequency (LF), High Frequency (HF), and Ultra-High Frequency (UHF).

- UHF (Ultra-High Frequency): This is the gold standard for the apparel industry. Its core strengths include long-range reading, high-speed data acquisition, and the ability to penetrate cardboard boxes. All RFID Clothing Tags discussed in this guide operate on the UHF frequency by default.

- Pro-Tip on NFC vs. UHF: The technology used for mobile payments (like Apple Pay), transit cards, or office access badges is NFC (High Frequency), which requires close-range “tapping” to work. Consequently, standard smartphones (excluding specialized industrial models) cannot scan UHF apparel tags. This frequency gap serves as a natural barrier to protect corporate data security.

1.2 Deep Dive: Why UHF is the “Perfect Match” for Apparel

To further explain why the industry focuses almost exclusively on UHF, we can break it down into three dimensions:

A. Technical Superiority: Group Reading and Distance

- Long-Range Capability: Unlike LF or HF, which require proximity of less than 10cm, UHF can be read from a distance of 3 to 10 meters. This allows warehouse staff to inventory high shelves without needing ladders.

- High-Speed Bulk Scanning: UHF protocols feature advanced anti-collision algorithms. When passing through an RFID tunnel or using a handheld PDA, hundreds of tags can be identified per second, achieving near-instantaneous bulk data capture.

- Packaging Penetration: UHF signals effectively penetrate cardboard and plastic packaging. This means garments can be verified at the unit level throughout the logistics process without ever needing to open a box.

B. Business Scenarios: Solving Supply Chain Pain Points

The apparel industry is characterized by high volume, massive SKU counts, and rapid turnover. UHF addresses these specific challenges:

- Instant Inbound/Outbound: With RFID tunnels, an entire carton of garments can be verified against a shipping order in seconds, increasing efficiency by hundreds of times compared to traditional barcode scanning.

- Rapid Store Inventory: A task that used to take three people an entire day can now be completed in minutes by one person walking the floor with a handheld reader.

- Geiger Mode Finding: Staff can use the signal strength of a UHF tag reader to “locate” a specific size or color within a crowded stockroom, much like a metal detector.

C. Data Security and Ecosystem Isolation

- Frequency Barriers: Because mobile phones operate on HF (13.56MHz) and apparel RFID operates on UHF (860-960MHz), ordinary consumers cannot easily read or tamper with the production and supply chain data stored in the woven labels.

- Controlled Access: This non-universality ensures that data remains within the enterprise’s internal loop, accessible only via professional industrial equipment.

Summary Comparison Table

| Feature | Low Frequency (LF) | High Frequency (HF/NFC) | Ultra-High Frequency (UHF) |

| Typical Use | Animal ID, Access cards | Mobile Pay, Transit cards | Apparel & Logistics |

| Read Distance | < 10 cm | < 10 cm | 3 – 10 Meters |

| Scanning Speed | Very Slow | Medium | Extremely Fast (Bulk) |

| Penetration | Strong (Liquid) | Medium | Excellent (Cardboard) |

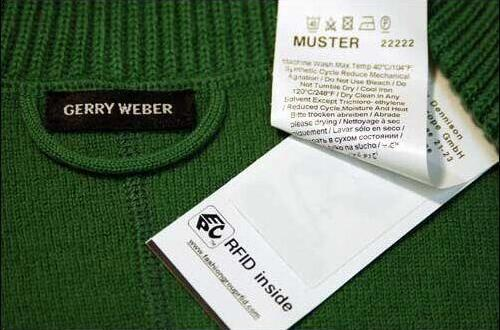

1.3 What is an RFID Clothing Label?

There are many types of RFID tags used in the apparel and footwear industry: RFID textile tags(woven labels), Self-adhesive RFID stickers, RFID hang tags, and dual-frequency RFID+EAS recyclable hard tags.

Among them, the Clothing RFID Tag is more than just a piece of fabric with washing instructions; it is a “Black Box sewn into the garment.” Unlike traditional hangtags, the Clothing RFID Tag (woven labels) enables Source Tagging: they are permanently fixed into the seams during the final stage of garment construction.

“Sandwich” Composite Process:

Since the Clothing RFID Tag must be as soft as ordinary fabric, the internal RFID Inlay (antenna + chip) uses an extremely thin polyester film substrate.

- Invisible Antenna: The internal etched aluminum antenna is specially designed so it won’t easily break or fail even after slight rubbing or bending.

- Physical Feel: Thickness is typically controlled between 0.18mm and 0.25mm.

1.4 Material Selection: From “Sensory Experience” to “Technical Performance.”

As an RFID tag manufacturer, Many clients focus only on price but ignore the compatibility between the material and the garment type.

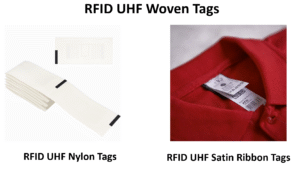

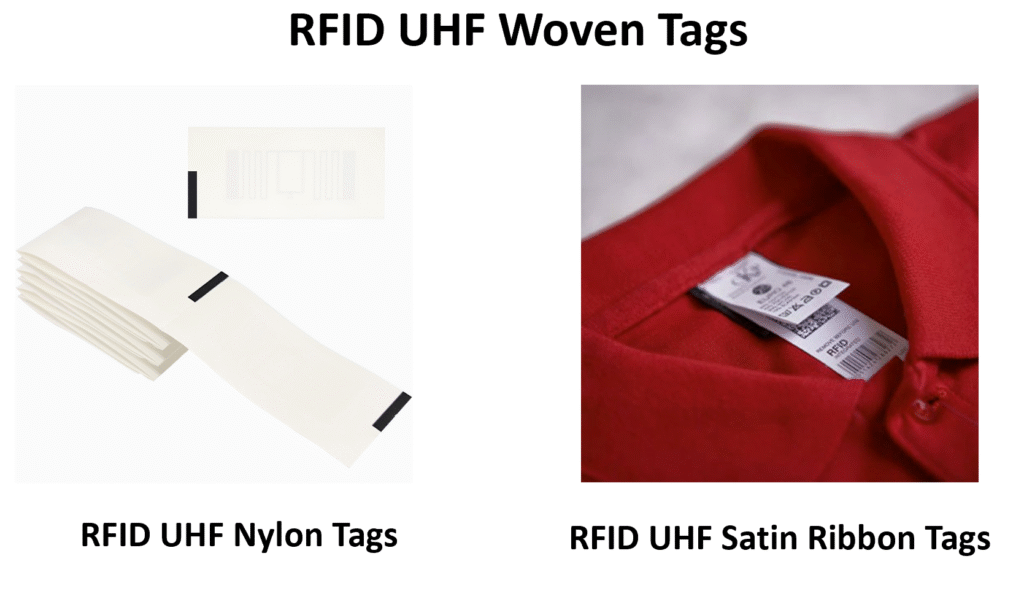

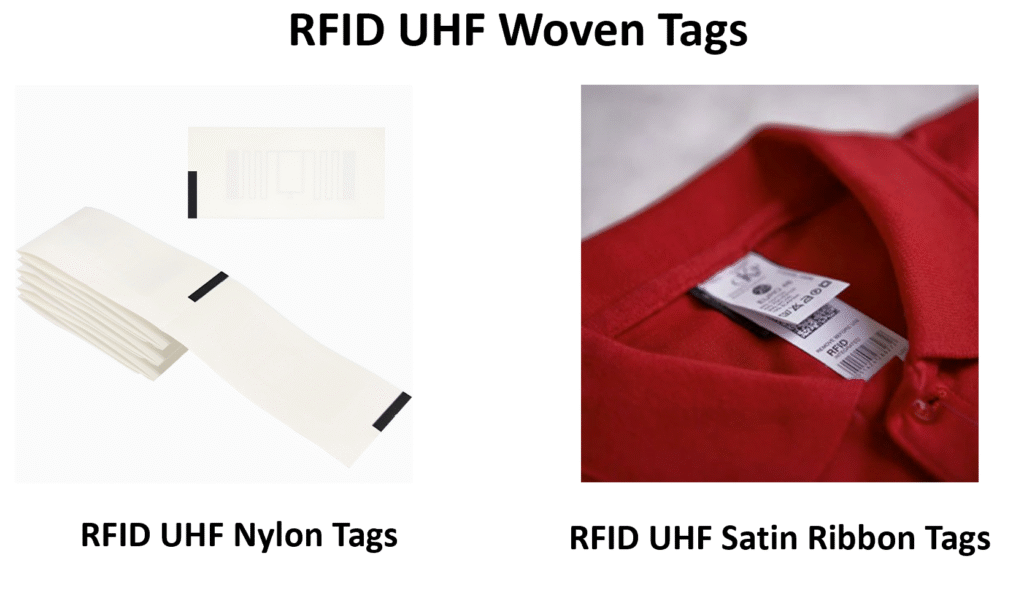

A. Nylon Taffeta — The “Pragmatist” for Efficient Logistics

- Visuals: Matte white surface, relatively stiff texture.

- Technical Traits: The surface is treated with a special coating for rapid ink absorption and strong color fixation. It ensures clear QR codes and washing symbols without ghosting during high-speed RFID printing.

- Best For: Denim, workwear (high abrasion resistance), and fast fashion (prioritizing readability and production speed).

- Note: If the edges are not handled well, there may be a slight “hard feel” (stinging sensation); thus, it is often sewn into the waist side or inner lining.

B. Satin — The “Guardian” of Brand Value

- Visuals: Elegant silky luster, extremely soft, and great drape.

- Technical Traits: Usually woven with heat-sealed or ultrasonic-cut edges to prevent fraying.

- Best For: Intimate apparel (underwear, loungewear) where 24-hour comfort is vital, and luxury/high-end fashion where touch is part of the brand experience.

- Note: Satin surfaces are slippery and require high-quality full-resin ribbons to ensure the print does not fade.

C. Polyester/Synthetic Fiber — The “Balance Point” for Extreme Durability

- Traits: Between Nylon and Satin; features excellent wrinkle resistance and chemical stability.

- Best For: Garments requiring mild chemical treatments or frequent laundering.

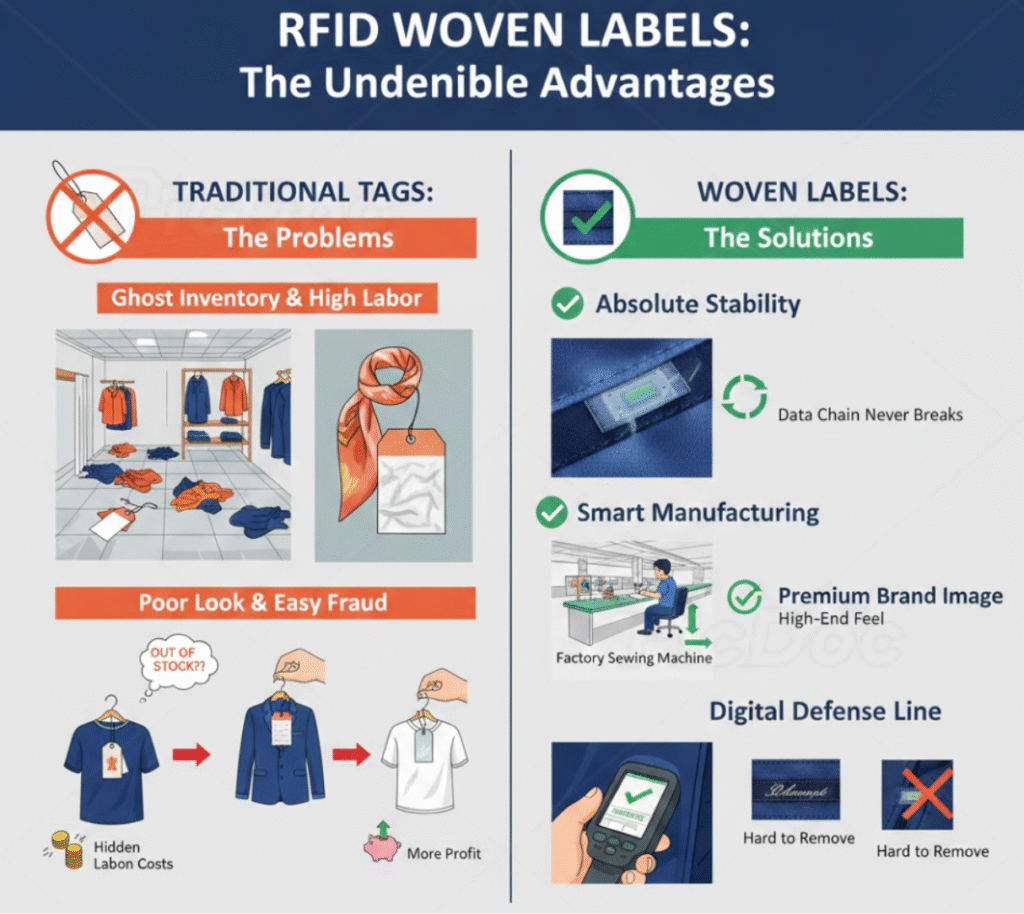

II. Why Choose RFID Textile tags(Woven Labels)? — Comparing the Three Main RFID Clothing Tags’ Formats

In the apparel industry, RFID garment tags typically take three forms: RFID Self-adhesive Stickers, RFID Hang tags, and RFID Woven Labels. Your choice determines data quality, installation cost, and user experience.

2.1. Comparison Table: Who is the “Efficiency King”?

| Dimension | RFID Textile tags(Woven Labels) | RFID Hang tag | RFID Self-adhesive Sticker |

| Form | Native: Sewn into seams | External: Hung on collar/sleeve | Patch: Stuck on hangtag back |

| Stability | Extreme: Data stays as long as the garment exists | Medium: Easily torn or lost during transit | Low: Adhesive can fail, peel, or be swapped |

| Security | Strong: Hard to remove without damaging the garment | Weak: A string can be cut easily | Very Weak: Stickers can be peeled and swapped |

| Brand Image | Premium: Seamless tech & fabric integration | Medium: Standard appearance | Poor: Ruins the aesthetic of the hangtag back |

| Total Cost | Low: Eliminates manual tagging labor costs | High: High cost for manual tagging/verification | High: Manual alignment & correction costs |

| Best Application | High-end fashion, Underwear, Full brand lines | Fast fashion, Low-priced consumables | Temporary promotions, E-commerce shipping |

2.2. Why RFID Textile tags (Woven Labels) Win (Deep Dive)

A. Eliminating “Ghost Inventory”: Absolute Physical Stability

- The flaw of Hangtags/Stickers: Paper hangtags and stickers are “external attachments.” During high-frequency trials in fitting rooms or turbulent logistics, hangtags break easily, and stickers tend to peel off. Once a tag is lost, the garment becomes a “Ghost” in the system—it is physically present in the store, but the computer shows it as “out of stock.”

- The Victory of Woven Labels: Woven labels are sewn into the side seams or collars, becoming an “organ” of the garment. This “native” attribute ensures that the data chain remains unbroken from the moment it leaves the factory until the final sale.

B. The Economics of “Source Tagging”: Converting Labor Costs into Manufacturing Costs

- Hidden Costs of Hangtags/Stickers: Although stickers themselves are cheap, you need to hire significant labor for “secondary processing” at warehouses or stores—alignment, sticking, stringing, and verification. These scattered labor costs and the cost of re-tagging due to errors represent a staggering hidden expense.

- The Victory of Woven Labels: Woven labels are integrated into the production line “in passing” during the sewing stage at the garment factory. It transforms the tedious manual tagging process into a standardized industrial production process. When calculating the Total Cost of Ownership (TCO), woven labels often prove to be more economical.

C. Brand Dignity: “Non-Intrusive” and “High-End” Technology

- The Embarrassment of Stickers: A plain white electronic sticker on the back of a beautifully designed brand hangtag instantly downgrades the brand’s aesthetic.

- The Dignity of Woven Labels: Made from satin or nylon, woven labels have a smooth, premium feel. To the consumer, it is simply a high-quality care label; to the brand, it is an invisible digital identity. This “understated” sense of sophistication is the bottom line for high-end brand digital transformation.

D. Security & Anti-Counterfeiting: An Irremovable Digital Defense Line

- The Risks of Hangtags/Stickers: Malicious actors can easily tear off RFID stickers from high-priced items and swap them onto low-priced ones.

- The Defense of Woven Labels: Sewn-in labels are extremely difficult to remove without damaging the garment. This provides a natural barrier for anti-counterfeiting verification: upon a return or exchange, scanning the woven label inside the seam instantly identifies if the item has been “swapped.”

Summary: Your Choice Determines the Quality of Your Data

- If you only seek short-term “inventory capability,” stickers and hangtags are simple entry-level tickets.

- If you pursue long-term “accurate data,” “ultimate user experience,” and “true process automation, then RFID Woven Labels are the standard configuration for brand digitization in 2026.

III. Field Implementation: Building Your RFID Textile tags(Woven Labels Closed-Loop Application

The successful implementation of RFID woven labels is never a simple “buy and sell” transaction; it is a synergy of hardware, industrial processes, and software. To make the chip sewn inside the garment functional, three core links must be integrated.

3.1. Encoding: Transforming “Fabric Strips” into “Digital IDs.”

RFID chips are typically blank when the woven labels leave the factory. The simultaneous “Printing + Encoding” must be completed via industrial-grade specialized RFID printers.

- Equipment Selection and Configuration:

- Thermal Transfer Printing: You must use industrial printers that support RFID read/write functions. Unlike standard printers, these feature a read/write antenna beneath the print head that accurately captures the chip’s position as it passes and writes EPC data.

- Ribbon Matching: Woven surfaces have tiny fibrous pores that ordinary wax ribbons cannot grip. You must use “Full Resin Ribbon.” These ribbons contain a high proportion of resin that melts under the high-temperature print head, “anchoring” itself into the fibers to achieve wash-resistant and scratch-resistant results.

- Technical Know-how:

- Automatic Defective Tag Rejection: Professional printers will automatically print an “X” mark or a black block on the surface of a label if a damaged chip (bad tag) is detected. The printer will then automatically skip it, ensuring that downstream sewing workers do not use defective tags.

- Cutter Configuration: Since woven labels come in rolls, the printer must be equipped with a cutter module to achieve a seamless process of printing, encoding, and cutting in one go.

3.2. Sewing: Physical Protection in Industrial Production

This is the stage where “bulk loss” of RFID labels most frequently occurs. Many factories report tags that cannot be read, which is often due to improper sewing techniques.

- Safe Zone Design:

- The Chip is the core of the RFID Clothing tag label. It is extremely tiny and fragile; it cannot withstand direct penetration by a sewing needle or heavy compression from a presser foot.

- Standard Operation: When designing the label, a “Sewing Zone” and a “Core Zone” must be clearly defined. The width of the sewing zone is usually reserved at 3mm-5mm. Factory supervisors must conduct pre-job training for workers to ensure that stitches remain only within the reserved edge area and never cross the center of the label.

- ESD Control (Electrostatic Discharge):

- In dry winter environments, sewing machines can easily generate high-voltage static electricity. If static is conducted through the needle to the chip, it can break down the internal circuitry. It is recommended to install anti-static table mats or maintain ambient humidity to ensure the electrical safety of the chips.

3.3. Collection: Achieving the Efficiency of “Second-Level Stocktaking.”

Once products enter the warehouse or retail store, the performance of the read/write equipment directly determines the user experience.

- Scanning Techniques for Handheld Terminals (PDA):

- Polarization Matching: RFID signals are directional. If the RFID garment tag antenna is sewn horizontally, the handheld scanner should also be held at a specific angle to achieve the best “group reading” effect.

- Dynamic Power Adjustment: When performing large-scale warehouse inventory, increase the power to cover a range of 5-8 meters. When searching for a single item (Geiger Mode), decrease the power to pinpoint the specific product.

- Batch Reading Platforms (Smart Checkout):

- Shielding Interference: Checkout counters in retail stores are usually designed with a Shielded Box structure. This ensures that the reader only scans the RFID textile labels inside the checkout basket and does not misread tags worn by customers or those on nearby racks.

In addition to flexible handheld terminals, for factories and large logistics centers pursuing ultimate efficiency, the RFID Tunnel Reader is the core equipment.

- RFID Tunnel Reader / Portal: The “Harvester” of Batch Identification

- Application Scenarios: Mainly used for warehouse inbound/outbound logistics and finished goods carton verification at factories.

- Working Principle: Fixed readers and high-gain antennas are installed at a conveyor belt or warehouse gate to form a closed or semi-closed signal field. When a whole carton of garments or a rack of hanging items passes through, the tunnel senses all the woven labels inside within 1-2 seconds.

- Technical Advantages:

- Anti-Leakage Shielding: Professional tunnels feature physical shielding to ensure they only read the carton passing through the gate, preventing misreads from nearby stock.

- Automatic Interception: If the physical items inside the carton do not match the outbound order (extra or missing items), the system will automatically trigger an alarm and stop the conveyor belt.

- Efficiency Comparison: Traditional manual carton opening for barcode scanning takes 5-10 minutes per box; an RFID Tunnel takes only 2 seconds, increasing efficiency a hundredfold.

3.4 The Data Brain: Why Must Your ERP/WMS be RFID-Compatible?

This is a common blind spot for many customers: an RFID tag only outputs a string of hexadecimal code (the EPC). It does not directly tell the system, “I am a red shirt.”

3.4.1. The Data “Translator”: RFID Middleware

- Function: Hardware captures “physical signals,” but the business requires “logical data.” Middleware is responsible for filtering duplicate signals (for example, if a tag is read 50 times, the system only records it once), managing hardware status, and streaming cleaned data to the backend software.

3.4.2. Three Major Thresholds for ERP/WMS Compatibility

If your current software system (ERP, Warehouse Management System (WMS), or Retail POS) lacks an RFID compatibility module, you will face the following challenges:

- Coding Mismatch: Traditional systems only support SKU-level management (one code shared by the same style and color), whereas RFID enables item-level management (one unique code per garment). The system database must be capable of accommodating a unique UID for every single piece of clothing.

- Concurrent Processing Capability: A defining characteristic of RFID is the “instant generation of massive data.” An RFID tunnel can read 500 RFID Clothing tags per second; if the software’s processing power is insufficient, it may cause system crashes or data loss.

- Real-time Synchronization Logic: The system needs to support specific RFID business logic, such as “bulk inbound processing” and “second-level stocktaking.”

3.4.3. What Do Customers Need to Prepare in Advance?

- Interface Confirmation: Ask your ERP vendor if the system provides standard API interfaces to support RFID data import.

- Data Structure Upgrade: Confirm whether the system can record and track the entire lifecycle of every EPC code (from factory production to warehouse, to store, and finally to sale).

- Local vs. Cloud: Considering warehouse reading speeds, we recommend an architecture of “Local Collection + Asynchronous Upload” to prevent network fluctuations from affecting loading and dispatching efficiency.

As an RFID tag manufacturer, we often tell our clients, “RFID hardware without software support is merely an expensive decoration.” While procuring RFID woven labels, it is essential to involve your IT department or software vendor for a joint evaluation. If your ERP is outdated, we can provide professional RFID adaptation plugins to help legacy systems seamlessly integrate with this new technology.

V. Usage Environment and Precautions: A Comprehensive “Pitfall Avoidance” Guide

The performance of RFID tags(RFID Labels) depends not only on chip quality but also on the “physical environment” in which they are placed. Below, we break down invisible risk points across production, warehousing, and retail.

4.1. Production and Ironing: Protecting the Fragile “Heart.”

- High-Temperature Alert Line: The internal chip and antenna are connected via micro-welding processes.

- Detailed Pitfall: Steam from industrial irons often exceeds 100°C, and the metal plates of pressing machines are even hotter. Pressing directly on the chip position can melt the encapsulation adhesive or deform the antenna.

- Practical Advice: It is recommended to sew the label into the inner side seam and clearly mark the care label with “Avoid ironing this label.” An additional “pass-through test” should be added during the factory quality inspection stage to eliminate labels accidentally damaged by ironing.

- Sewing Machine Puncture Risk:

- Detailed Pitfall: Many factories use fully automatic template machines or high-speed flat sewing machines. If a needle pierces the center of the chip, the RFID label is scraped, and the needle may even break.

- Practical Advice: The RFID label designs should use “cold-cut edges” and reserve a 5mm sewing zone. Workstations should be marked with red warning signs to remind workers that the “needle position must not cross the line.”

4.2. Warehouse Scenarios: “Physical Games” in Bulk Environments

In the warehouse, RFID faces the challenge of “group reading” thousands of tags simultaneously.

- Metal Shielding and Reflection:

- Risk: If your shelves are pure metal or the clothing itself contains a large number of metal buttons, sequins, or metal wires, radio waves will be reflected or absorbed.

- Pitfall Details: If a label is placed directly against a metal shelf, the reading distance will drop sharply to less than 10cm. The solution is to ensure a gap of at least 2cm between the label and metal supports during display or use read/write antennas with anti-metal capabilities

- Shadowing Effect:

- Risk: When hundreds of pieces of underwear or shirts are tightly squeezed into a cardboard box, “mutual interference” can occur between chip antennas.

- Pitfall Details: This phenomenon can make items in the center of the box unreadable. The solution is to use tunnels equipped with “polarization-switching antennas” to penetrate the stacked layers through multi-angle, high-power scanning.

- Packaging Humidity:

- Risk: Moisture is the nemesis of UHF signals.

- Pitfall Details: If the warehouse environment is extremely humid or the fabric itself is highly moisture-absorbent (such as heavy wool sweaters), the reading rate will drop. Warehouses must be kept dry, and reading sensitivity calibration should be performed before large-batch inbound processing.

4.3. Retail Store Scenarios: Balancing User Experience and Precision

In-store, RFID faces a messy signal environment and non-professional operators.

- Over-reading:

- Risk: A clerk scans a garment at the checkout counter, but the system also picks up clothes on a rack 3 meters away.

- Pitfall Details: This is the most common store complaint. The solution is to install an “RFID shielding cover” at the checkout counter or use “near-field read/write antennas” to lock the identification distance within 30cm, preventing accidental charges.

- Anti-theft System “Blind Spots”:

- Risk: While RFID woven labels can prevent theft, they are not as conspicuous as hard magnetic tags, and if a human body blocks the label, alarm sensitivity will decrease.

- Pitfall Details: You cannot rely solely on RFID woven labels for anti-theft. They should be used as an invisible auxiliary in coordination with in-store digital monitoring systems.

- Consumer Tag Cutting:

- Risk: Although the woven labels are skin-friendly, some consumers still have the habit of cutting off all garment labels.

- Pitfall Details: It is recommended to design the RFID woven label as the main brand label or sew it in a hidden part of the inner side seam. Printing a beautiful brand logo can guide consumers to view it as a brand mark rather than a “trash label” to be removed.

4.4. Follow-up Issues: Handling Damaged Tags and Data Confusion

- Failure Rate:

- No electronic product is 100% perfect. There is typically a 0.1% to 0.3% loss rate during garment production.

- Pitfall Advice: The ERP system must have a process for “damaged tag re-printing” and “single-item replacement.” Once a damaged label is found, staff should be able to unbind the old code and quickly associate a new label via a handheld device.

- Data Conflicts:

- Avoid assigning the same EPC code to two different pieces of clothing (duplicate codes).

- Pitfall Advice: A unified cloud-based encoding platform must be used to allocate code sequences, and OEMs are strictly prohibited from generating codes privately.

💡 Summary: Details Determine ROI An RFID Textile tag (Woven Labels)is not just a simple consumable; it is a physical engineering project. By focusing on “penetration” in the warehouse, “boundaries” in the store, and “heat avoidance” during production, your RFID investment can truly translate into high inventory turnover.

VI. RFID Tag Price: Are RFID Textile tags Expensive?

When discussing costs, many clients’ first reaction is to compare unit prices: while a standard RFID woven label might cost only a few cents, an RFID woven label can be several times more expensive. However, if we evaluate management efficiency across the entire garment lifecycle, the conclusion changes completely.

5.1. Breakdown: Cost Composition of RFID Woven Labels

To understand the price, we must look at where the investment goes:

- Hardware (Chip + Antenna): This is the core component. Currently, UHF (Ultra-High Frequency) chips are the mainstream standard. Prices are influenced by global semiconductor market fluctuations and order volume (e.g., 100k vs. 1M units).

- Materials and Encapsulation: Using premium satin or nylon and the specialized composite process required to “implant” a micro-chip into textiles is inherently more costly than standard paper printing.

- Market Price Reference: According to the current rate, the average price for RFID Textile tags (Woven Labels)typically ranges from $0.03 to $0.7 USD per unit.

- Price Variable Factors: It is important to note that final pricing varies significantly based on:

- Order Quantity: Bulk orders significantly drive down unit costs.

- Label Size: Larger labels require more material and larger antennas.

- Chip Type: Specialized chips (e.g., high-memory or high-sensitivity models) carry a premium.

- Customization: Specific weave patterns or complex printing requirements will affect the quote.

- Production Loss: Every single woven label undergoes 100% electrical performance testing before leaving the factory; the cost of discarding defective tags is factored into the final price.

5. 2. The “Subtraction” of Hidden Costs: Why RFID Textile tags Can Save Money

While the unit price of a woven label is higher, it often wins on the Total Cost of Ownership (TCO):

- Elimination of Manual Tagging Fees:

- RFD Hang tag/Sticker Mode: These tags are cheaper, but you must pay labor costs at the warehouse or store to manually apply them to every single item. In mass production, this labor cost often exceeds the price difference of the label itself.

- Woven Label Mode: Factory workers sew the label in during the standard production process, making the additional labor cost virtually zero.

- Reducing “Ghost Inventory” Losses: Because woven labels are permanently attached, they do not fall off. You avoid losing track of stock or being forced to clear items at a steep discount due to missing identifiers. The recovered gross profit from these saved sales is often enough to cover the label’s premium.

5.3. Return on Investment (ROI): When Will You See a Return?

Based on industry big data, the profit points for adopting RFID woven labels come from three main areas:

| Profit Source | Data Improvement | Financial Impact |

| Inventory Accuracy | From 70% to 99% | Reduces customer complaints from overselling and losses from deadstock. |

| Stocktaking Efficiency | 10-20x Increase | Dramatically cuts store labor time, allowing staff to focus on sales. |

| Search Speed | 80% Improvement | Instantly locate specific sizes/colors to prevent potential lost sales. |

5.4. Expert Advice: How to Optimize Your Budget?

- Tiered Procurement: Not all garments require the most expensive materials. Use Satin for intimate apparel or silk items, and Nylon for outerwear or trousers to optimize costs.

- Core Styles First: If your budget is limited, pilot the program with high-value, fast-turning, or high-risk items (like down jackets or suits) to verify the ROI before a full rollout.

- Long-term Agreements: As RFID technology becomes more ubiquitous, unit prices are gradually decreasing. Locking in a strategic long-term contract with a supplier can secure better pricing.

VII. Pre-Project Launch: What Do You Need to Prepare? (Checklist)

Implementing RFID Textile tags (Woven Labels) is a systematic engineering project. To ensure a smooth transition from “lab testing” to “large-scale mass production,” it is recommended to internally organize the following five categories of information before formally engaging with a rRFID Label Manufacturer:

6.1. Physical Attribute Confirmation (Physical Dimension)

- Material Preference: Confirm the garment type; Satin is recommended for intimate apparel, while Nylon is recommended for outerwear or sportswear.

- Size Constraints: Measure the existing wash-care label position; due to antenna length limitations, it is generally recommended that RFID Textile tags (Woven Labels) be no less than 30mm wide and 50mm long.

- Folding Process: Confirm how the label is presented on the garment; options include Center Fold, End Fold, or Straight Cut, which directly affects the encapsulation position of the internal chip.

6.2. Encoding and Printing Requirements (Data Dimension)

- Encoding Logic: Determine if you have an existing EPC encoding rule or if the supplier needs to initialize and write data for “one item, one code” implementation.

- Surface Printing: Identify what needs to be printed on the label surface besides the chip data, such as washing icons, composition details, logos, or fixed/variable barcodes.

- Software Compatibility: Confirm if your ERP or WMS system has reserved RFID data interfaces capable of handling item-level dynamic data streams.

6.3. Production Equipment Assessment (Hardware Dimension)

- Printing Equipment: Check if existing printers support RFID reading and writing; if not, evaluate purchasing industrial-grade RFID printers and compatible full-resin ribbons.

- Collection Equipment: Inventory the number of devices needed for stores and warehouses:

- Does the warehouse require RFID tunnel readers?

- How many handheld PDAs are needed for stores?

- Does the checkout area require fixed scanning platforms?

6.4. Environmental Testing and Process Simulation (Environmental Dimension)

- Metal and Liquid Assessment: Inform technical staff if garments contain significant metal accessories or conductive fibers for necessary antenna tuning.

- Worker Training Plan: Prepare “Standard Operating Procedures” for sewing workers, clearly defining chip avoidance zones to prevent unnecessary tag damage during sewing.

6.5. Defective Tag Handling Mechanism (Emergency Dimension)

- Re-printing Process: Determine if small RFID printers are available at the factory or warehouse for immediate replacement of damaged tags.

- System De-registration: Ensure the software supports voiding damaged codes and quickly binding new codes.

6.6. Awareness and Attitude: Achieving Top-Down Consensus

- Management’s Strategic Resolve: Decision-makers must realize that RFID woven labels are a digital transformation infrastructure, not just a simple consumable replacement; it must be viewed as a long-term investment.

- Full Staff Acceptance: From leadership to technicians, warehouse staff, and store clerks, there must be positive recognition of RFID technology; staff should understand it aims to reduce repetitive labor and increase accuracy, not monitor work.

Recommendation: From “Small Steps” to “Full Coverage”

Most clients should follow a “Three-Step” strategy:

- Sampling and Testing: Obtain a small batch of sample packs in different materials for sewing and washing tests.

- Small-Scale Pilot: Test the data logic in a single product category or a specific store for 1-3 months.

- Full-Scale Rollout: Implement source tagging across all brands after verifying the Return on Investment (ROI).

Conclusion: From “Perception” to “Decision”—Starting a Brand’s Digital Era

An RFID Textile tag (Woven Label) is more than just a strip of fabric; it is the unique passport connecting every product to the digital world. In today’s highly competitive retail market, RFID technology empowers brands with three core capabilities:

- Full-Chain “X-ray Vision”: Eliminates inventory blind spots by achieving 100% real-time visibility from factory to store.

- High-Speed “Harvester”: Increases the efficiency of inventory, inbound logistics, and checkout by a hundredfold, freeing employees from tedious scanning.

- Item-Level “ID Card”: Provides an irreplaceable physical foundation for anti-counterfeiting, anti-swapping, and precision marketing.

Choosing RFID woven labels is essentially choosing a higher dimension of management language. While transitioning from barcodes to RFID requires “Top-Down” determination and over a year of patience for integration, the reward is the ability to manage brand assets at the individual “item” level rather than just the “style” level. In the marathon of digital transformation, those who establish a precise data closed-loop first will gain true certainty in an ever-changing market.